A kind of method of manufacturing vanadyl sulfate

A technology of vanadyl sulfate and vanadium clinker, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problems of difficult treatment of ammonium-containing acidic wastewater, long process flow, low yield, etc., to avoid pollution and Consumption of manpower and material resources, simplification of operation procedures, and high vanadium yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

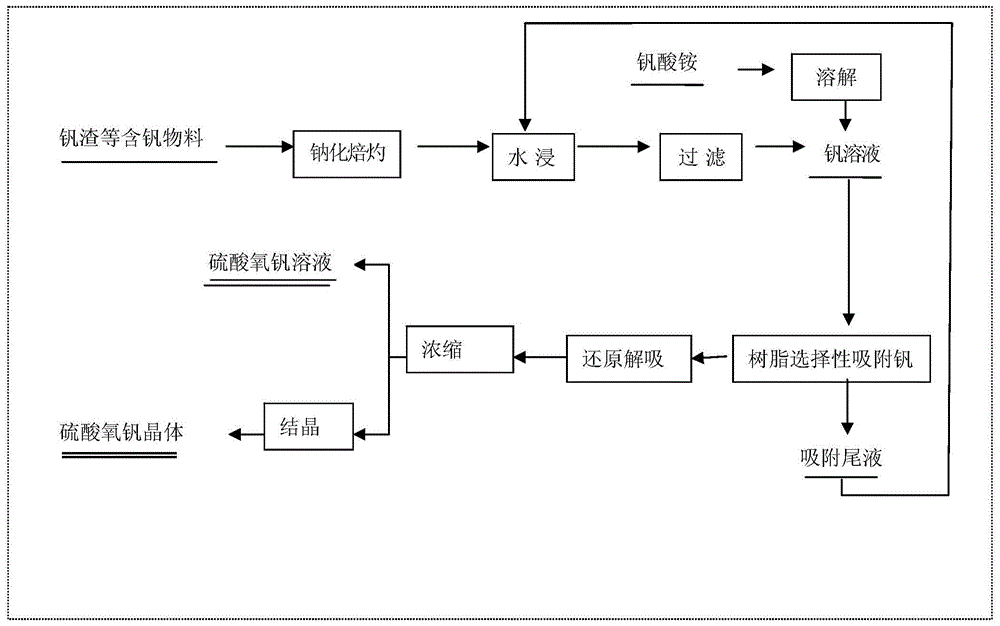

Method used

Image

Examples

Embodiment 1

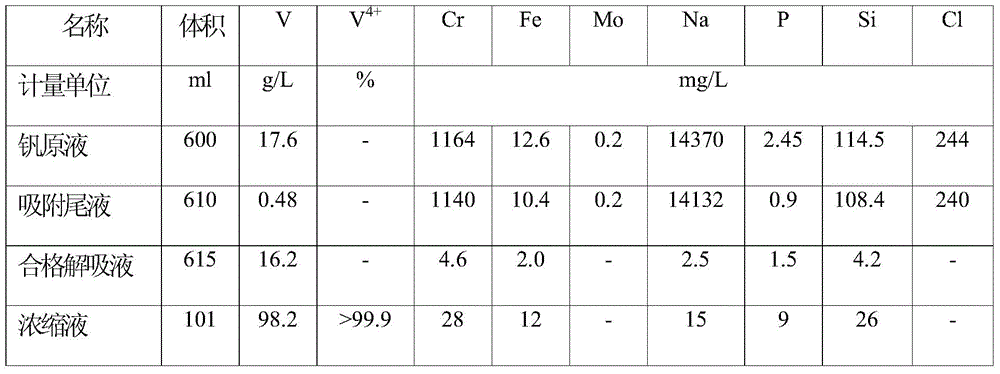

[0032] Take 200ml of vanadium extraction resin, put it into a plexiglass fixed-bed exchange column of Φ22mm×800mm, and the height of the resin layer is about 526mm. Wash the resin downstream with a small amount of deionized water until the effluent is clear. Accurately measure 600ml of vanadium stock solution, flow through the fixed bed at a speed of 400ml / hour, collect the effluent, which is marked as the adsorption tail liquid, and accurately record the volume of the solution, and wash the vanadium-loaded resin with a small amount of deionized water.

[0033] Take 600ml of the prepared reducing desorbent to desorb the vanadium-loaded resin. The reducing desorbent composition is: 2%H 2 SO 3 +4%H 2 SO 4 The mixed solution flows through the fixed bed at a speed of 200ml / hour, collects the effluent, and desorbs the solution to become blue high-purity VOSO 4 solution. After desorption, wash the resin with a small amount of deionized water, and then enter the next cycle to a...

Embodiment 2

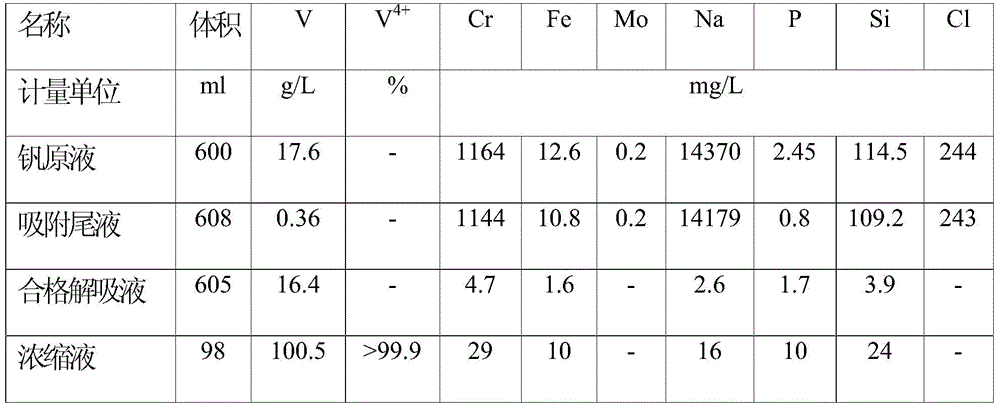

[0041] Take 200ml of resin and put it into a Φ22mm×800mm plexiglass fixed bed exchange column, the height of the resin layer is about 526mm. Wash the resin downstream with a small amount of deionized water until the effluent is clear. Accurately measure 600ml of vanadium stock solution, flow through the fixed bed at a speed of 600ml / hour, collect the effluent, which is marked as the adsorption tail liquid, and accurately record the volume of the solution, and wash the vanadium-loaded resin with a small amount of deionized water.

[0042] Take 600ml of the prepared reducing desorbent to desorb the vanadium-loaded resin. The reducing desorbent consists of: 5% H 2 SO 3 +10%H 2 SO 4 The mixed solution flows through the fixed bed at a speed of 200ml / hour, collects the effluent, and desorbs the solution to become blue VOSO 4 solution. The effluent is marked as a qualified desorption solution, and the volume of the solution is accurately recorded. After desorption, the resin is...

Embodiment 3

[0050] Take 200ml of resin and put it into a Φ22mm×800mm plexiglass fixed bed exchange column, the height of the resin layer is about 526mm. Wash the resin downstream with a small amount of deionized water until the effluent is clear. Accurately measure 600ml of vanadium stock solution, flow through the fixed bed at a speed of 400ml / hour, collect the effluent, mark the effluent as adsorption tail liquid, and accurately record the volume of the solution, wash the vanadium-loaded resin with a small amount of deionized water .

[0051] Take 600ml of the prepared reducing desorbent to desorb the vanadium-loaded resin. The reducing desorbent composition is: 8%H 2 SO 3 +15%H 2 SO 4 The mixed solution flows through the fixed bed at a speed of 200ml / hour, collects the effluent, and the desorbed solution is VOSO 4 solution. The effluent is marked as a qualified desorption solution, and the volume of the solution is accurately recorded. After desorption, wash the resin with a sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com