Method and device for producing polymer nanofibers with high-speed airflow and high-voltage static electricity

A high-voltage electrostatic and nanofiber technology, which is used in fiber processing, stretch spinning, textiles and papermaking, etc., can solve problems such as the lack of high-pressure airflow guide, the low spinning efficiency, and the low liquid conductivity. , to achieve the effect of low residual solvent content, uniform thickness and increased flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

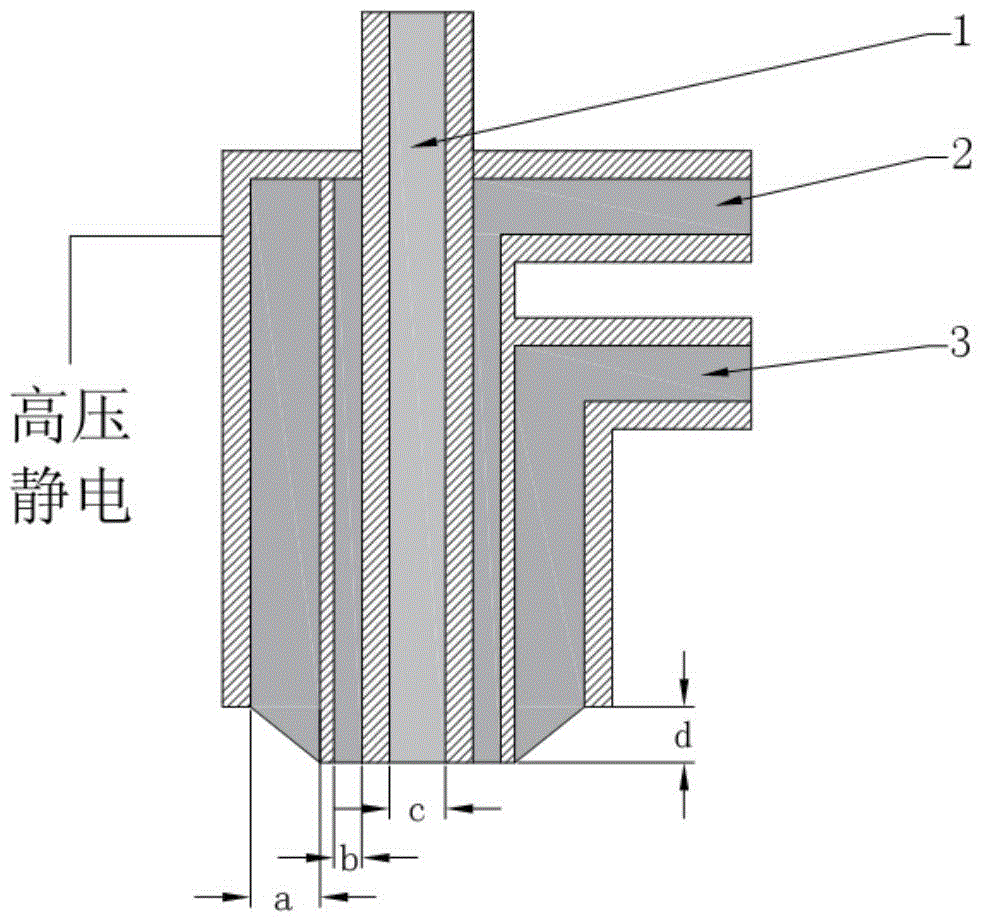

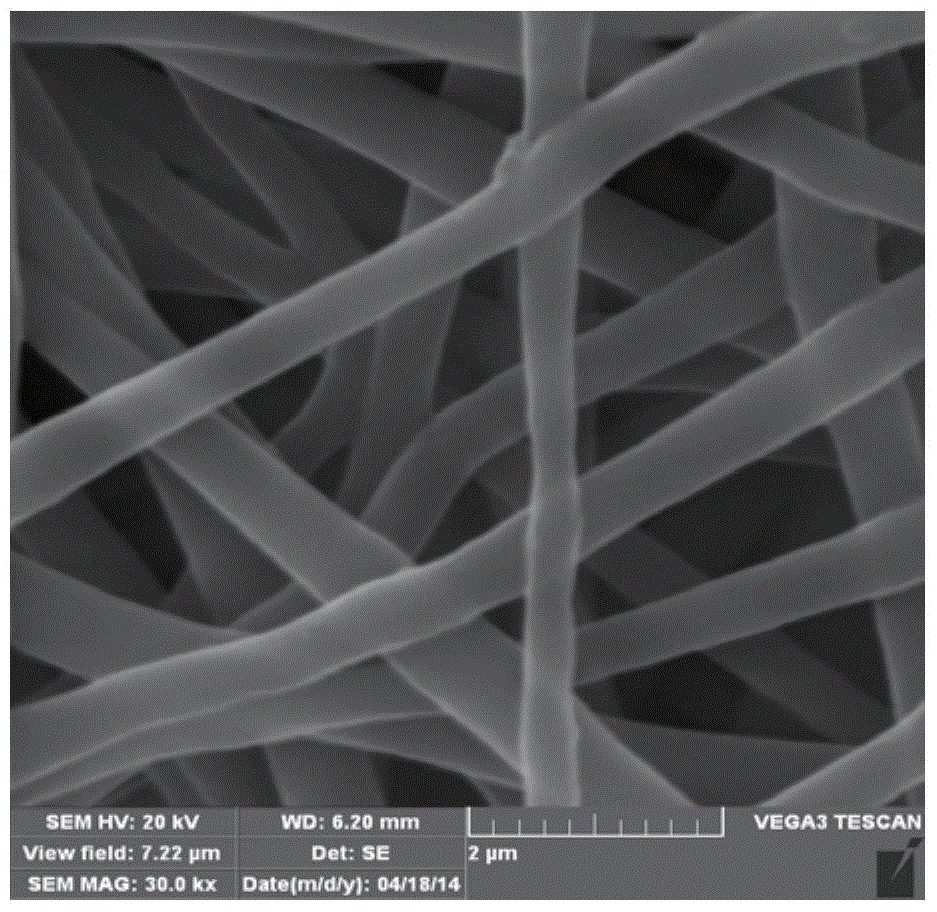

[0034] Example 1: Preparation of polyacrylonitrile (PAN) nanofibers

[0035] PAN powder is dissolved in N,N-dimethylacetamide (DMAc) solution, and a small amount of conductive agent N,N,N-trimethyl-4-dodecylphenylammonium chloride is added to prepare PAN quality A spinning solution with a percentage concentration of 12%, an absolute viscosity of 4.2 Pa.S, and an electrical conductivity of 50 μS / cm is ready for use. Adjust the air pressure parameters of the spinneret so that the air pressure of the inner air flow channel 1 is 0.7 MPa, the air air pressure of the outer air flow channel 3 is 0.6 MPa, the width "a" of the air outlet gap of the outer air flow channel 3 is 1.5 mm, and the air pressure of the inner air flow channel 3 is 1.5 mm. The air outlet aperture "c" of layer air flow channel 1 is 0.5mm, the height difference "d" of the air outlet of the inner and outer layer air flow channel is 3.0mm, and the width "b" of the spinning solution outlet gap is 0.2mm; from the spin...

example 2

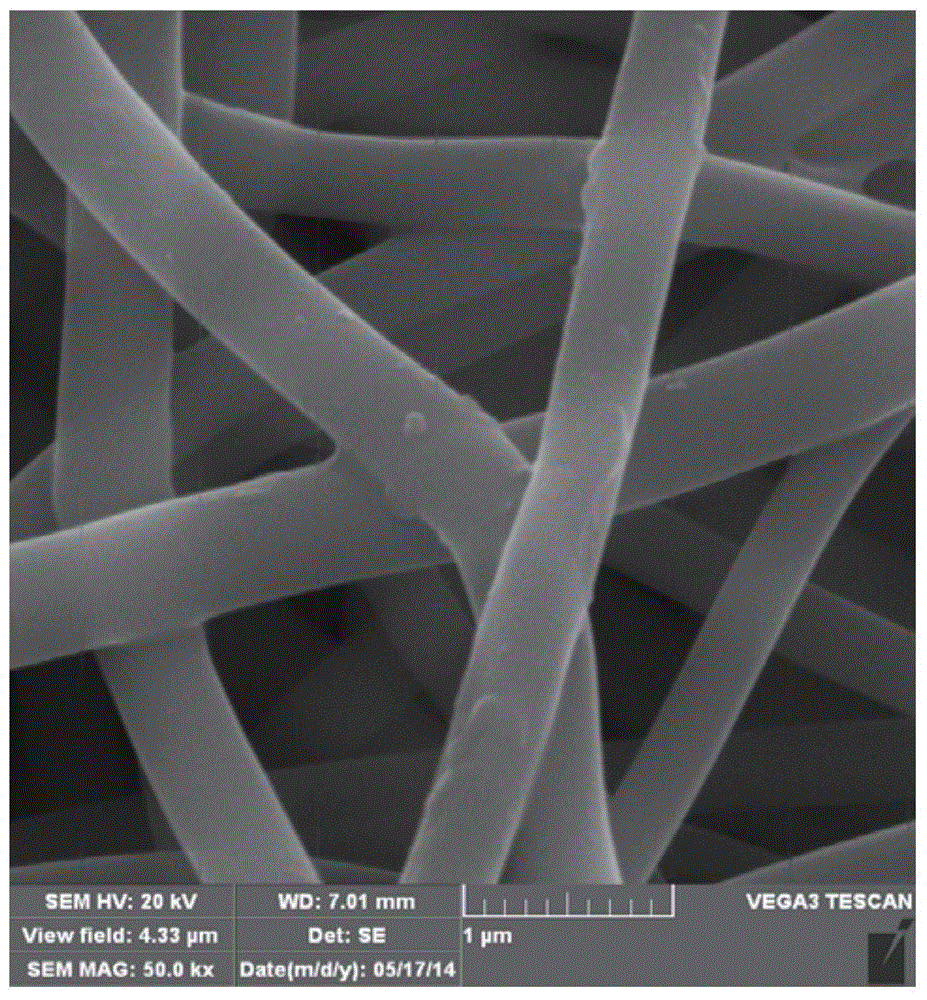

[0036] Example 2: Preparation of polyamic acid (PAA) ultrafine nanofibers

[0037] Take 50 g of DMAc solution of polyamic acid (PAA) with a mass concentration of 20% and an intrinsic viscosity of 1.2 dL / g, dilute with 12.5 g of tetrahydrofuran (THF), and add a small amount of conductive agent N, N, N-trimethyl- 4-dodecylphenylammonium chloride, making the spinning solution with a mass concentration of PAA of 16%, an absolute viscosity of 4.0 Pa.S, and an electrical conductivity of 65 μS / cm for use. Adjust the air pressure parameters of the spinneret so that the air pressure of the inner air flow channel 1 is 1.0 MPa, the air air pressure of the outer air flow channel 3 is 0.8 MPa, the width "a" of the air outlet gap of the outer air flow channel 3 is 0.8 mm, and the air pressure of the inner air flow channel 3 is 0.8 mm. The air outlet hole diameter "c" of layer air flow channel 1 is 1.0mm, the height difference "d" of the air outlet of the inner and outer air flow channel is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com