Conical concrete pile tip, tubular pile provided with pile tip and production method of tubular pile

A technology for concrete piles and a manufacturing method, applied in the directions of manufacturing tools, sheet pile walls, reinforcing forming, etc., can solve the problems of uneven welding quality of picket piles, small stress-bearing area of the cone tip, affecting the quality of pile foundations, etc. Insufficient bearing capacity of the pile tip, good integrity, and the effect of eliminating the welding connection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

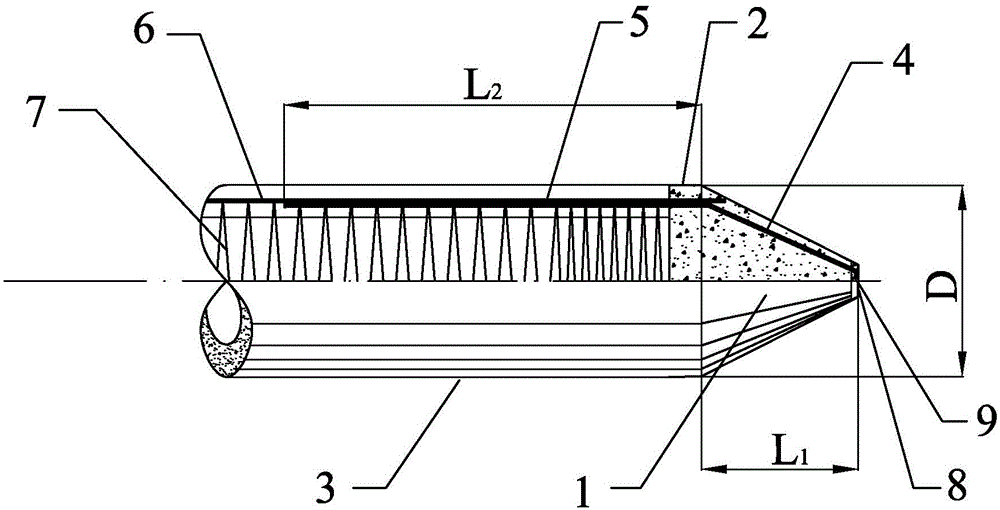

[0033] Such as figure 1 As shown, a cone-shaped concrete pile point, the pile point is a cone-shaped pile point formed by pouring concrete from the pile point main body 1, wherein the pile point body 1 includes a positioning plate 8 arranged at the end of the small head of the cone , the positioning plate 8 adopts a steel plate, and a hole 9 is arranged in the middle of the positioning plate 8, and a plurality of pile tip side ribs 4 are uniformly welded on the positioning plate 8 according to the standard reinforcement quantity of the pipe pile to form the pile tip main body 1 The end of the pile tip side rib 4 is fixed on the positioning plate 8, that is, it is fixed around the hole 9, and the pile tip is not fixed when the pile tip is assembled by screw tightening. Offset phenomenon occurs; the tail of the pile tip side rib 4 is provided with a bending part 5 for pouring to form the transition section 2 between the pile tip and the pile body, and the bending part 5 is conne...

Embodiment 2

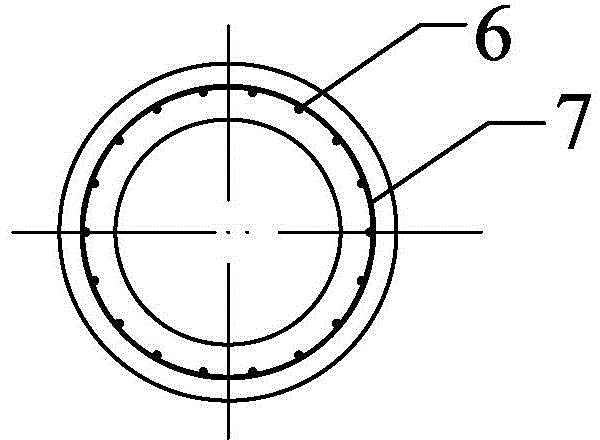

[0036] Such as figure 1 , 2 As shown, a pipe pile with the above-mentioned cone-shaped concrete pile point, the pipe pile is formed by the prestressed main reinforcement 6 of the pile body body 3 first and the bending part of the pile point side rib reinforcement 4 of the pile point 5 is formed by pouring concrete after being fixed, wherein the pile main body 3 includes prestressed main reinforcement 6 matching the number of side ribs 4 of the pile point and braided and wound around the outer periphery of the prestressed main reinforcement 6 with As for the stirrup 7 constituting the reinforcement cage of the pipe pile, the bending part 5 of the rib bar 4 on the side of the pile point and the main prestressed bar 6 are fixed by iron wires.

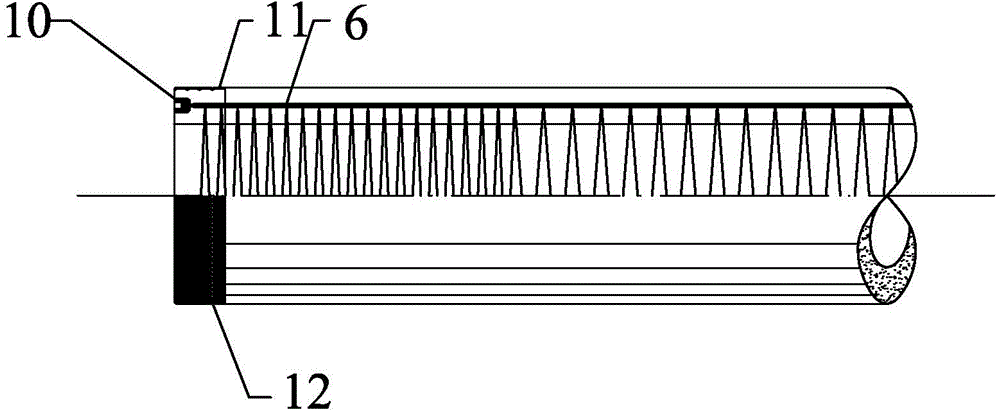

[0037] Such as image 3 , 4 As shown, the tail end of the pipe pile is provided with a plurality of anchor sleeves 10 for fixing the prestressed main reinforcement 6, and a pile hoop 11 is fixed outside the tail end of the pipe pile. A...

Embodiment 3

[0040] A method of manufacturing the above pipe pile, comprising the steps of:

[0041]Step 1: Make the main body 1 of the pile point, bend the steel bars into the side ribs 4 of the pile point, and then evenly weld and fix them on the positioning plate 8 to form the frustum-shaped skeleton of the pile point main body 1, and keep the side ribs of the pile point The height of the ribs 4 is consistent, and the ribs 4 on the side of the pile tip also include a bending part 5 for forming the transition section 2 between the pile tip and the pile body;

[0042] Step 2: Pouring the pile tip, place the pile tip body 1 in the pile tip mold, and there are evenly a number of reserved main reinforcement holes in the pile tip mold, and clean the mold opening and the inner wall of the mold and apply an appropriate amount of demoulding Put the iron shoe cover into the pile tip mold, cover the mold cover and screw the pile tip rod and check whether the iron shoe cover is perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com