Compact composite material power transmission line tower

A technology of power transmission lines and composite materials, applied in the field of power transmission and distribution engineering, can solve the problems of high probability of gap discharge accidents, small insulation margin of insulator strings, and high probability of discharge accidents, so as to reduce the width of corridors, ensure safe operation, and save projects. effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

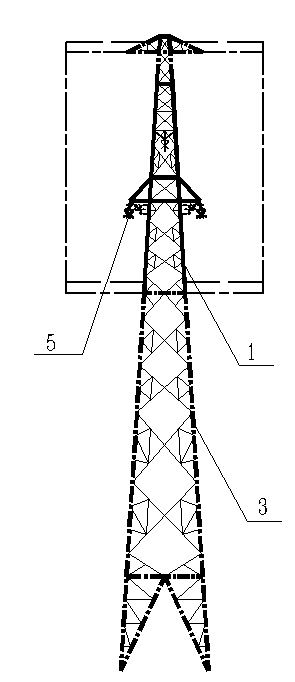

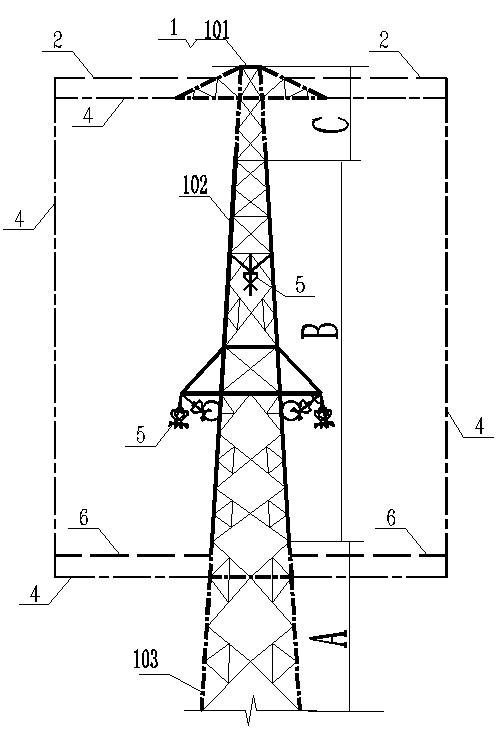

[0017] Example 1, such as figure 1 and figure 2 Shown: a compact transmission line tower made of composite materials, including a steel tower body 3, a tower head 1, and a wire hanging fitting 5; the tower head 1 includes an upper tower head 101, a middle tower head 102, a lower tower head 103, an The tower head 101 and the lower tower head 103 are steel tower heads, the middle tower head 102 is a composite material tower head, the lower end of the upper tower head 101 is fixedly connected with the upper end of the middle tower head 102, and the lower end of the middle tower head 102 is fixed with the upper end of the lower tower head 103 Connection, wire hanging fittings 5 are installed in the tower head 102 in the middle section. In order to show the three-section tower head of the present invention clearly, the C section shown in the figure is the upper section head 101 , the B section is the middle section head 102 , and the A section is the lower section head 103 . ...

Embodiment 2

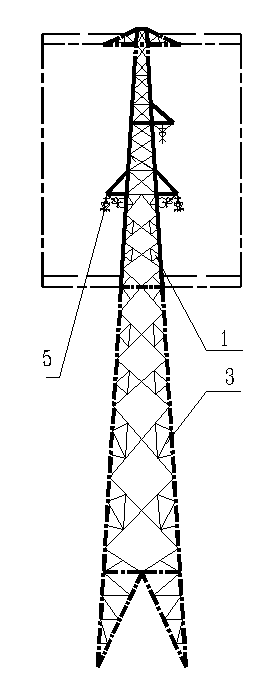

[0021] Example 2, such as image 3 and Figure 4 As shown: in the composite material compact transmission line tower provided in this embodiment, the wire-hanging fittings 5 installed on the tower head 102 in the middle section are arranged in an upward shape; On the left and right sides of the body, another wire fitting 5 is installed on the right side of the middle tower head 102 upper tower body; certainly another wire hanging fitting 5 can also be installed on the middle tower head 102 upper tower body on the left side. The three-phase conductors of this scheme are arranged in non-equilateral triangles, and the charge balance of the three-phase conductors is slightly worse than that of the regular triangular composite material compact scheme. Others are the same as in Example 1.

[0022] The equilateral triangular composite material compact transmission line pole tower implementation scheme provided in Example 1 and the up-shaped composite material compact transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com