Power cable sheath and installation method of the sheath

A sheath and power technology, applied in building types, buildings, towers, etc., can solve problems such as corrosion of wire-pulling hardware, hidden dangers of safe operation, and difficulty in finding wire-pulling hardware, so as to achieve the effect of prolonging service life and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The power cable sheath proposed by the present invention will be further described below in conjunction with the accompanying drawings.

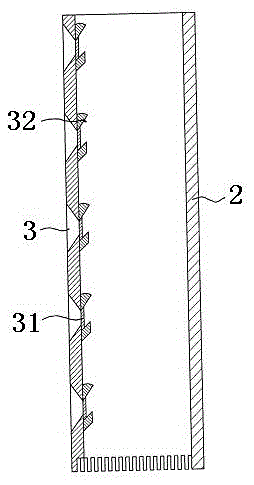

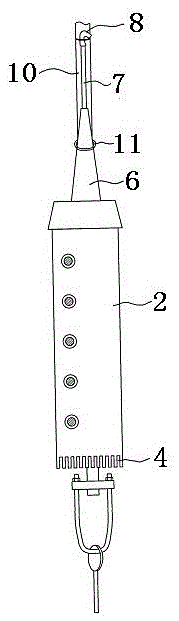

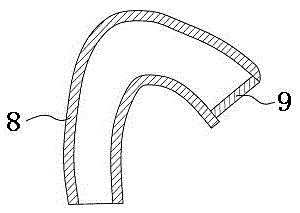

[0026] Such as figure 1 , figure 2 and image 3 Shown is the schematic diagram of the structure of the power cable sheath. The power cable sheath includes a sheath tube body 2 with an end cap 1 on the upper end, a plurality of vent holes 3 arranged in the axial direction are arranged on the sheath body 2, and There are a plurality of drainage grooves 4 arranged in the circumferential direction of the body, and a wire hole 5 is provided at the center of the end cover 1. On one side of the wire hole 5, a conical suction pipe 6 is provided, and an air guide pipe 7 is installed above the suction pipe 6. An elbow 8 is arranged at the upper end of the air duct 7 , and a first filter screen 9 is arranged at the end of the elbow 8 . Such as Figure 4 As shown, during installation, the vent hole 3 is positioned at the side of the backguy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com