Alternate cooling and heating yield increasing method for gas extraction bored well

A technology of gas drainage and alternating cold and heat, which is applied in the field of expanding coal fissures and increasing gas extraction volume, can solve the problems of small number of fissures, difficulty in forming long fissures, and low coal seam permeability, so as to speed up work efficiency, Realize the effect of effective utilization and efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

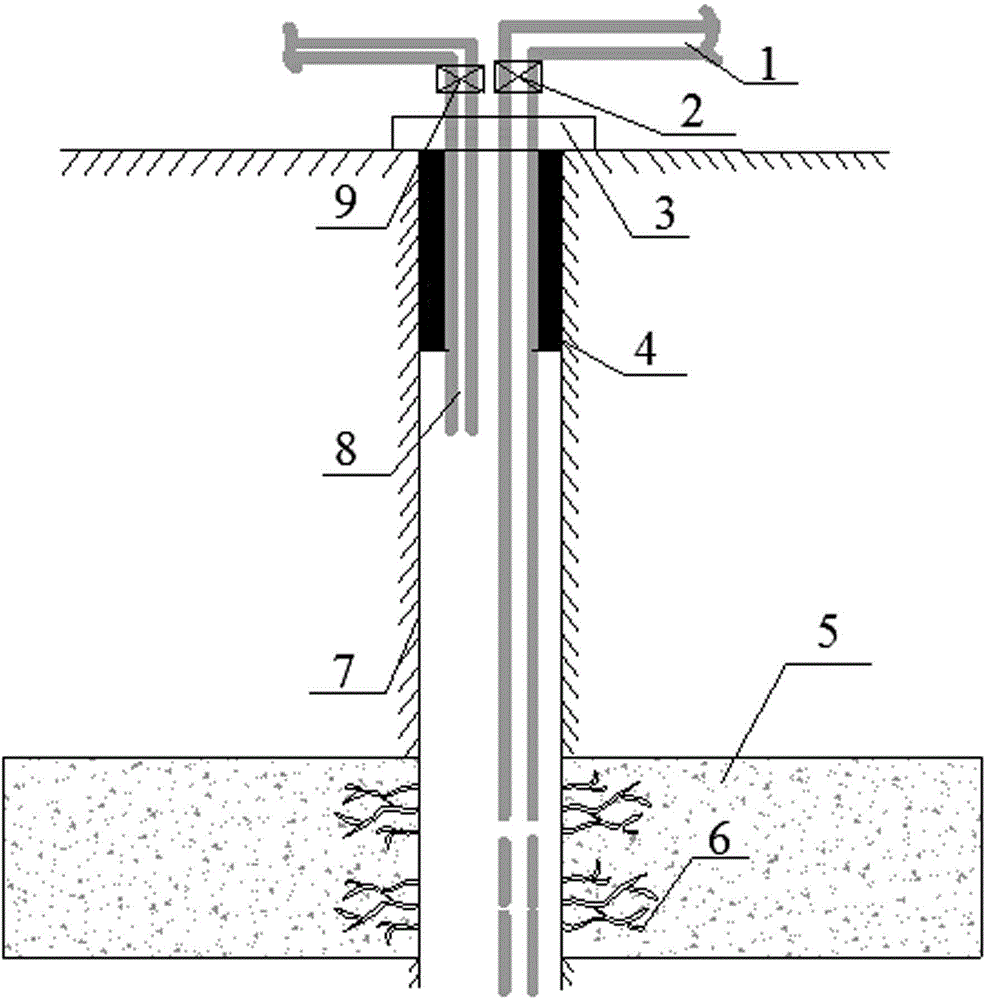

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the present invention is a method for increasing production by alternating cold and heat for gas drainage drilling, and the specific steps are as follows:

[0027] 1) Construct the ground drilling 7 to 0.5~1m above the bottom of the coal seam 5 (0.5m, 0.6m, 0.7m, 0.8m, 1.0m can be selected), and send the gas drainage pipe 1 and gas injection pipe into the ground drilling 7 in sequence 8. The gas drainage pipe 1 is sent to the bottom plate of the coal seam 5, and the gas injection pipe 8 is sent to the bottom beyond the sealing section 4; the gas drainage pipe 1 is connected to the valve I2, and the gas injection pipe 8 is connected to the valve II9;

[0028] 2) Water injection: open the valve II9 and inject a sufficient amount of 5~10MPa clear water into the ground well 7 through the gas injection pipe 8, so that the water enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com