High-thrust carrier rocket low-temperature final-stage storage-tank connection support structure design method

A technology of a carrier rocket and a support structure, which is applied in the field of space transportation systems, can solve the problems of low boiling point of cryogenic propellant, long-term storage and application limitations of cryogenic propellant in space, etc., and achieve the effect of blocking thermal transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

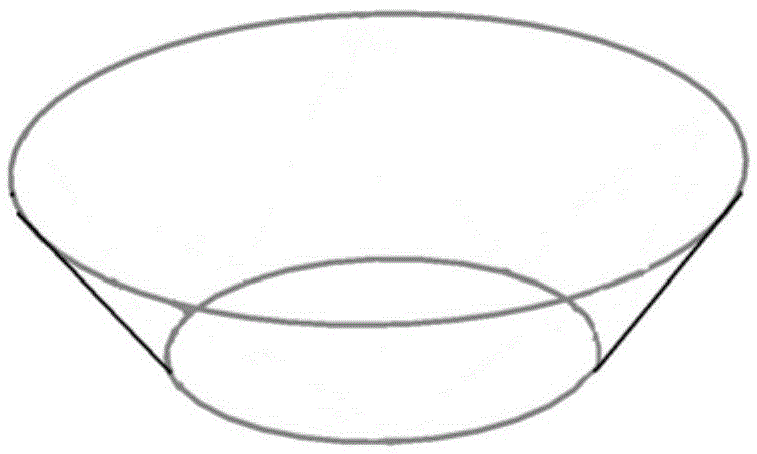

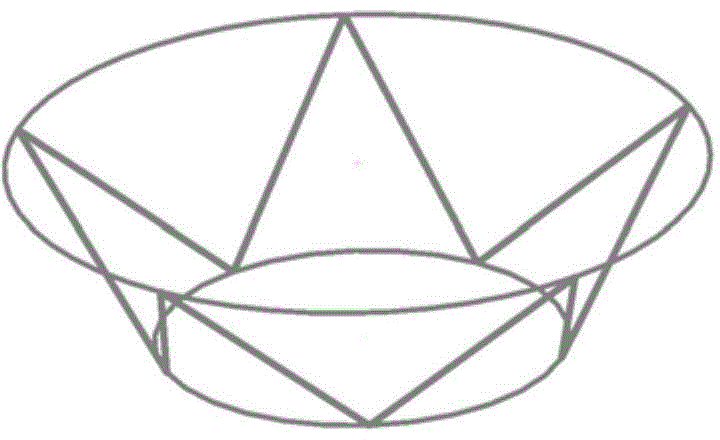

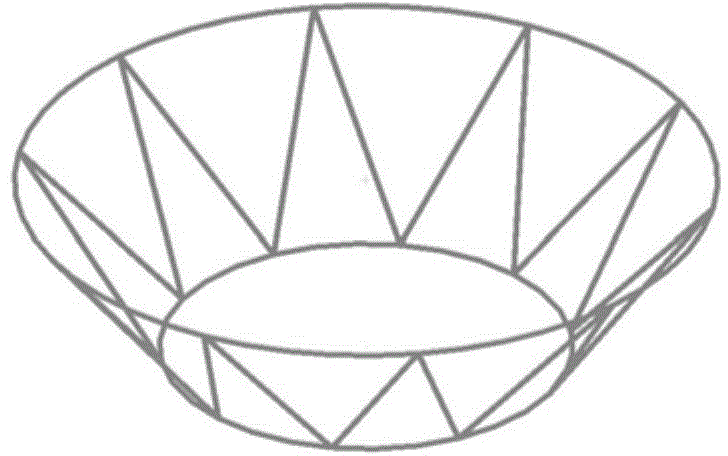

[0023] Attached below Figure 1-5 The present invention will be described in detail.

[0024] First, material selection

[0025] Based on the ratio of strength to thermal conductivity, material selection suitable for the temperature region is made.

[0026] In the flight segment of the launch vehicle, the maximum axial force that the connecting support structure bears can reach several million Newtons, and the lateral force can reach a maximum of several hundred thousand Newtons. The temperature of the cryogenic tank at both ends of the connecting support structure is about 20K and 90K, the boiling point temperature of the cryogenic propellant, respectively.

[0027] The optional materials for the connection support structure are mainly aluminum alloys, glass fiber composite materials, and carbon fiber composite materials.

[0028] Thermal properties of various materials

[0029]

[0030]

[0031] After analyzing the properties of the above materials, it can be seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com