High-load vibration isolator capable of adjusting rigidity and damping

A large load and vibration isolator technology, applied in the direction of shock absorber, shock absorber-spring combination, shock absorber, etc., can solve the problems of insufficient load bearing capacity, performance degradation, failure, etc., to meet the frequency characteristics and Energy dissipation properties, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

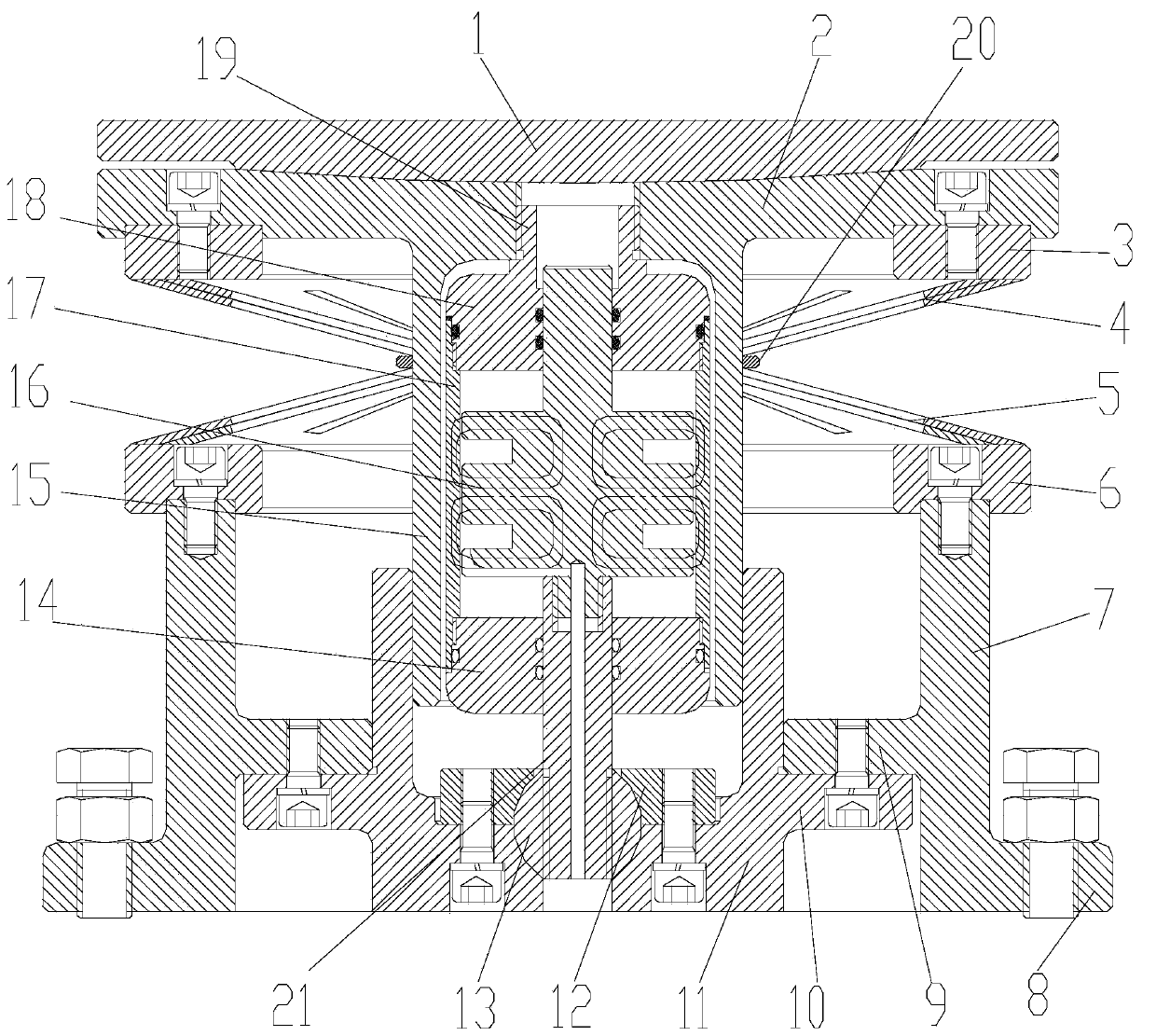

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0024] A vibration isolator with large load and adjustable stiffness and damping provided by the present invention includes a vibration isolation plate 1, a bearing platform, a magneto-rheological damper, a diaphragm spring and a supporting base;

[0025] The load-bearing platform includes a load-bearing plate 2, a sleeve 15, an upper diaphragm spring seat 3 and a lower diaphragm spring seat 6;

[0026] The vibration isolation plate 1 is arranged on the upper surface of the bearing plate 2;

[0027] The sleeve 15 is fixedly arranged on the lower surface of the load-bearing plate and the axis of the sleeve is perpendicular to the plate surface of the load-bearing plate, the magnetorheological damper is embedded in the sleeve, and the upper end of the magnetorheological damper It is fixedly connected with the bearing plate 2, the piston rod of the magneto-rheological d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com