Three-dimensional scanner and three-dimensional scanning method

A scanner and three-dimensional technology, applied in the field of three-dimensional scanners and three-dimensional scanning, can solve the problems of small scanning depth of field, high price, insufficient automatic stitching, etc., and achieve the effects of simple production, low cost, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

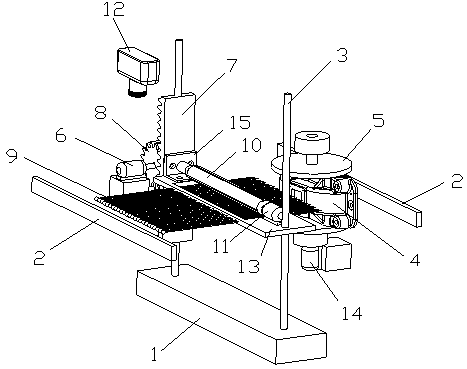

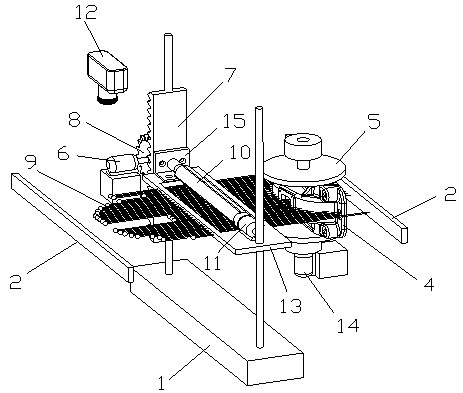

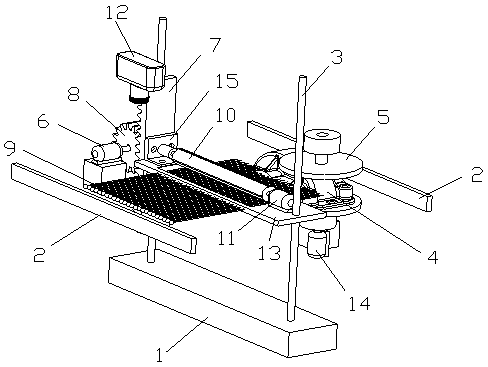

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] Referring to the accompanying drawings, a three-dimensional scanner includes a camera 12, a jig 5 for clamping a part 4 to be tested, a first drive motor 14 for driving the jig to rotate, and several irons that are on the same level and are spaced parallel to each other. quality probe 9, a probe installation platform 13 for installing each probe, a probe horizontal driving device for driving each probe to move horizontally and making each probe approach or away from the part to be measured, and a probe for driving the probe Install the probe up and down driving device that moves up and down on the platform. The far end of each probe 9 is provided with a red ball head. The camera 12 is used to take pictures of the red marks of each probe and input the picture data into the computer. The computer analyzes and recognizes it with a program. The horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com