Method for determining reliability of calendar life of airplane structure protection system

A protection system and aircraft structure technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of increased aircraft inspection and maintenance costs, increased aircraft use and maintenance costs, and corrosion of structural matrix materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

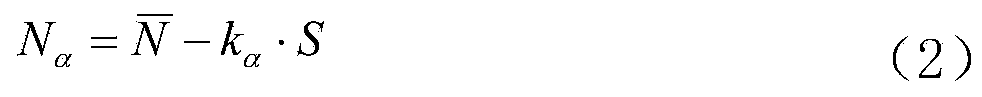

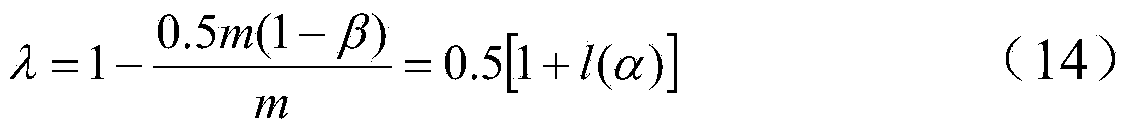

[0036] The selection of calendar life reliability of the aircraft structure protection system is closely related to the corrosion damage law of the structural matrix. The selected reliability should not only ensure the safety of the structure, but also from the economical point of view to minimize the maintenance cost of the aircraft.

[0037] The method for determining the calendar life reliability of the aircraft structure protection system of the present invention will be described in detail below in conjunction with specific embodiments.

[0038] The method for determining the calendar life reliability of the aircraft structure protection system of the present invention specifically comprises the following steps:

[0039] Step 1: Establish the relationship model between the corrosion damage amount of the structural matrix and the corrosion time

[0040] There are many types of damage to aircraft structural substrates in corrosive environments, such as pitting corrosion and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com