An automatic pressure regulating high pressure helium gas control system

An automatic pressure regulation and control system technology, applied in the direction of electric fluid pressure control, etc., can solve the problems of not being able to simulate gas working conditions well, high dependence on technical operators, and low terminal pressure smoothness, etc., to achieve Improve safety and emergency handling capabilities, reduce dependencies, and save a lot of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

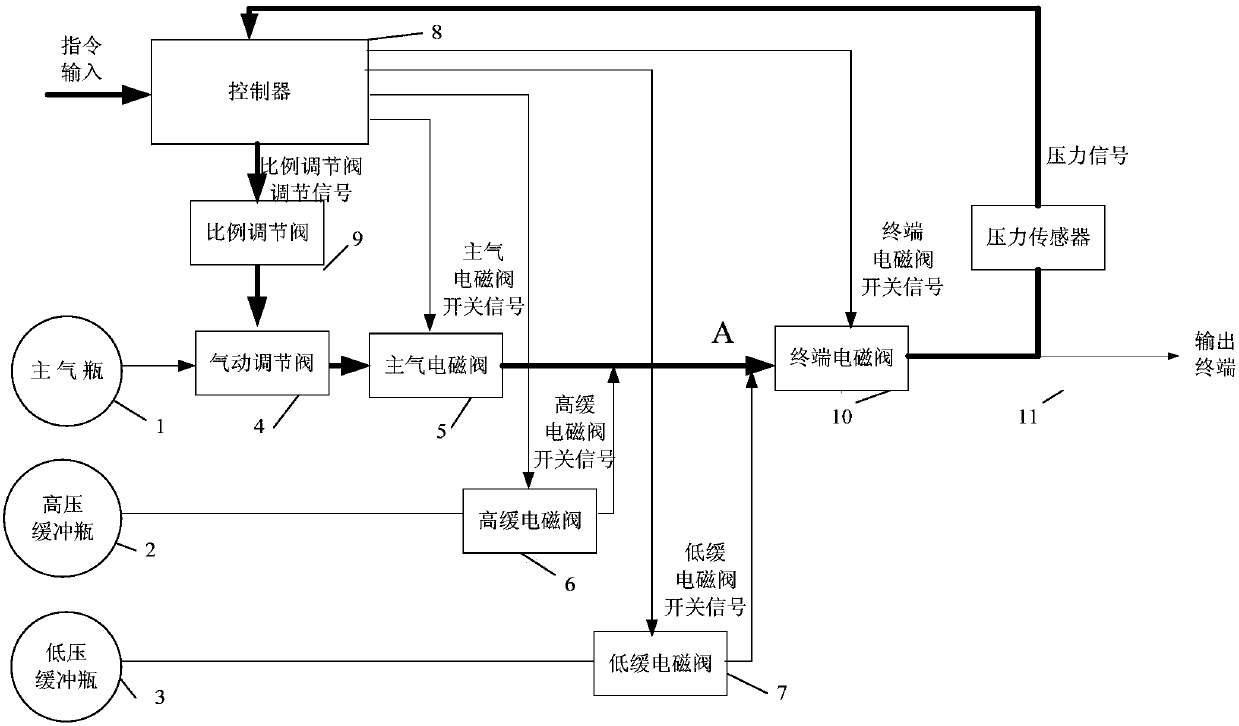

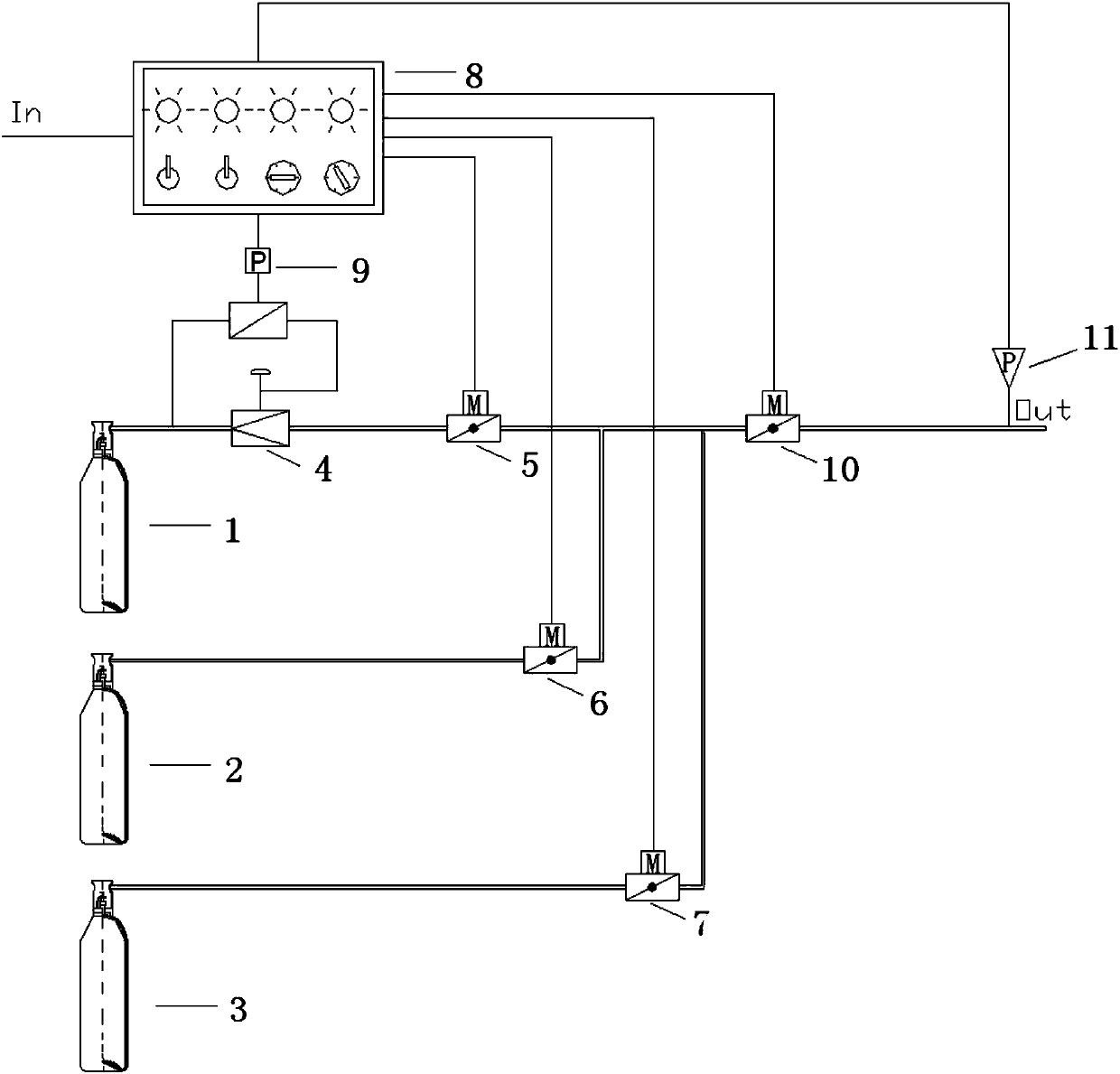

[0019] like figure 2 and image 3 As shown, the output interface of the main gas cylinder 1 is communicated with the input end of the pneumatic regulating valve 4 through the pipeline, the output end of the pneumatic regulating valve 4 is communicated with the input end of the main gas solenoid valve 5 through the pipeline, and the main gas solenoid valve 5 The output end communicates with the input end of the terminal solenoid valve 10 through a pipeline. The output interface of the high-pressure buffer bottle 2 communicates with the input end of the high-slow solenoid valve 6 through the pipeline, and the output end of the high-slow solenoid valve 6 communicates with the input end of the terminal solenoid valve 10 through the pipeline. The output interface of the pressure buffer bottle 3 is communicated with the input end of the slow sole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com