Optimized design method for modelling of end wall of high load fan/compressor

A technology of optimization design and end wall modeling, applied in computing, special data processing applications, instruments, etc., can solve problems such as speeding up optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0258] Example description:

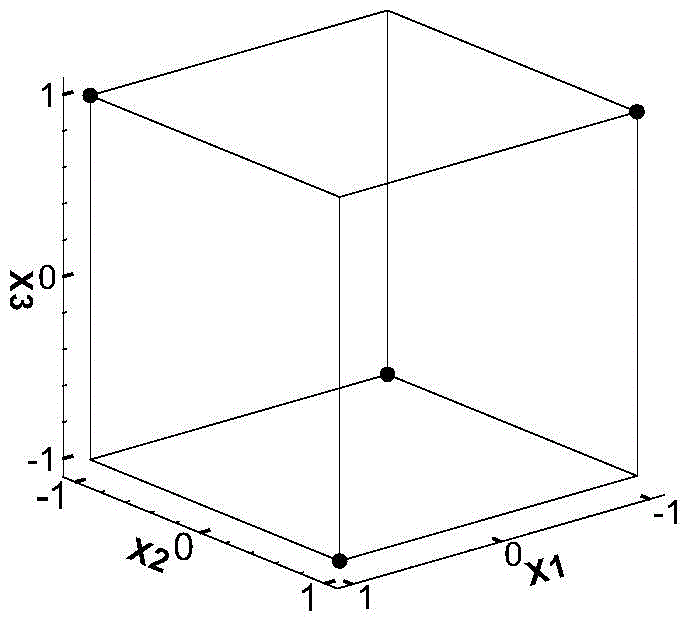

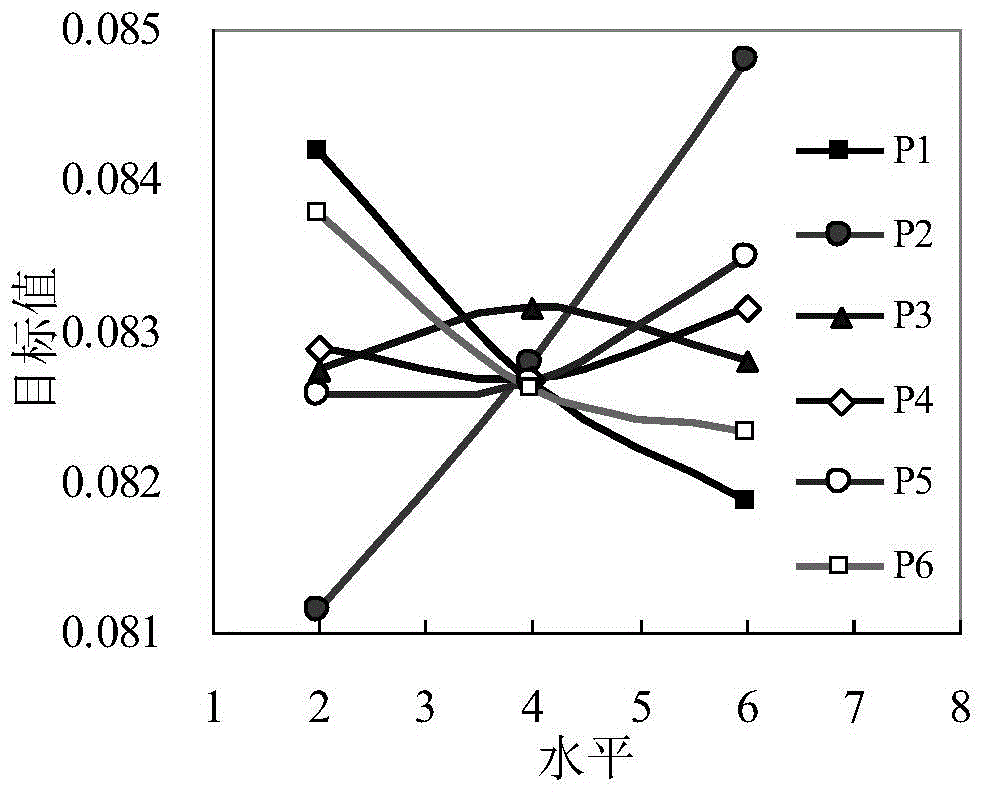

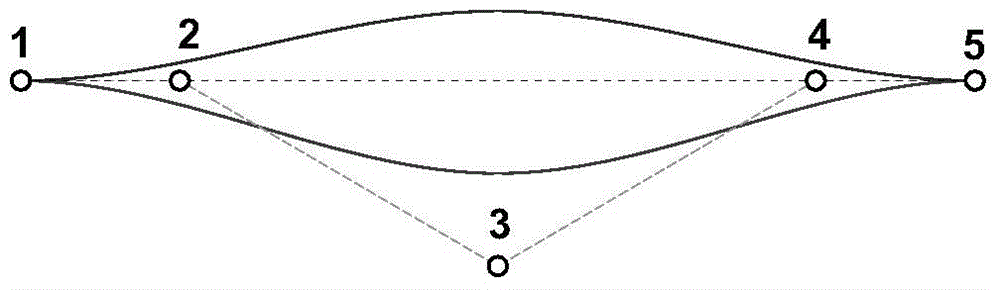

[0259] Using the developed end wall optimization platform, combined with the end wall parametric modeling method, the end wall of the compressor cascade is optimized non-axisymmetrically, and the effect of non-axisymmetric end wall technology on the internal flow of the cascade is initially explored. Finally, the feasibility of the present invention is verified by a comparative analysis with the reference end wall (flat end wall).

[0260] In view of the three-dimensional aerodynamic numerical optimization process in impeller machinery, the key technologies and difficulties in the optimization design of the end wall shape of the high-load fan / compressor can be summarized as follows:

[0261] 1) CFD numerical simulation in the optimization iteration process is very time-consuming

[0262] Aiming at the three-dimensional aerodynamic numerical optimization problem in impeller machinery, by establishing an approximate model for optimizing independent variable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com