An electron gun with a circular flat cold cathode with a circular truncated and cylindrical combined grid structure

A cold cathode and grid hole technology, applied in the field of electron guns, can solve the problems of cathode damage, electron beam trajectory divergence, ignition, etc., and achieve uniform distribution of electric field, avoid ignition, and good emission uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

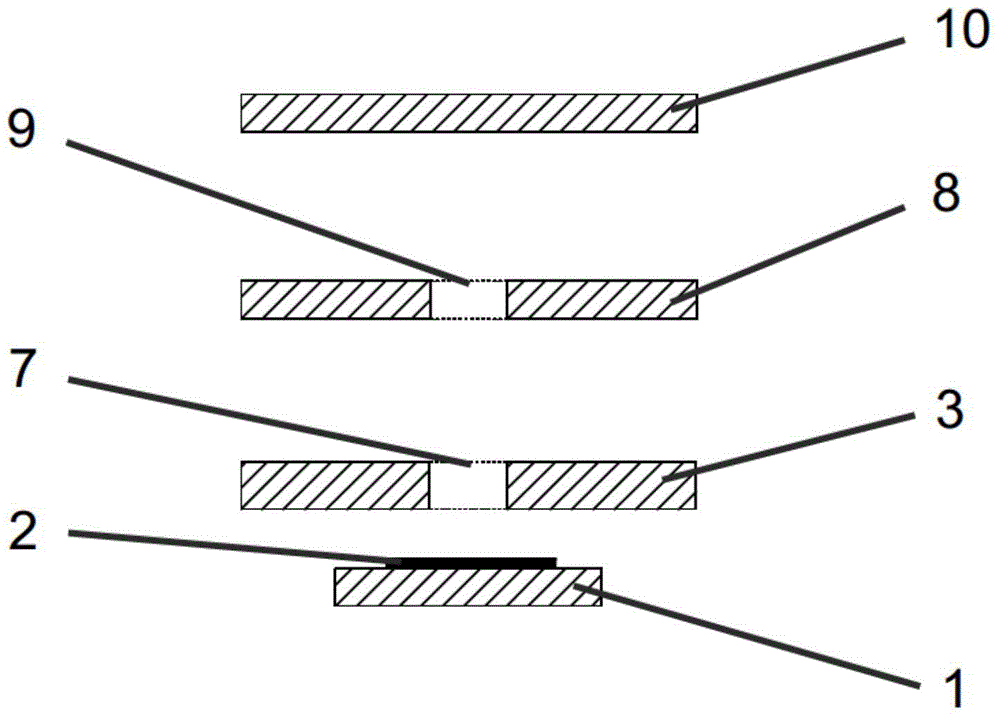

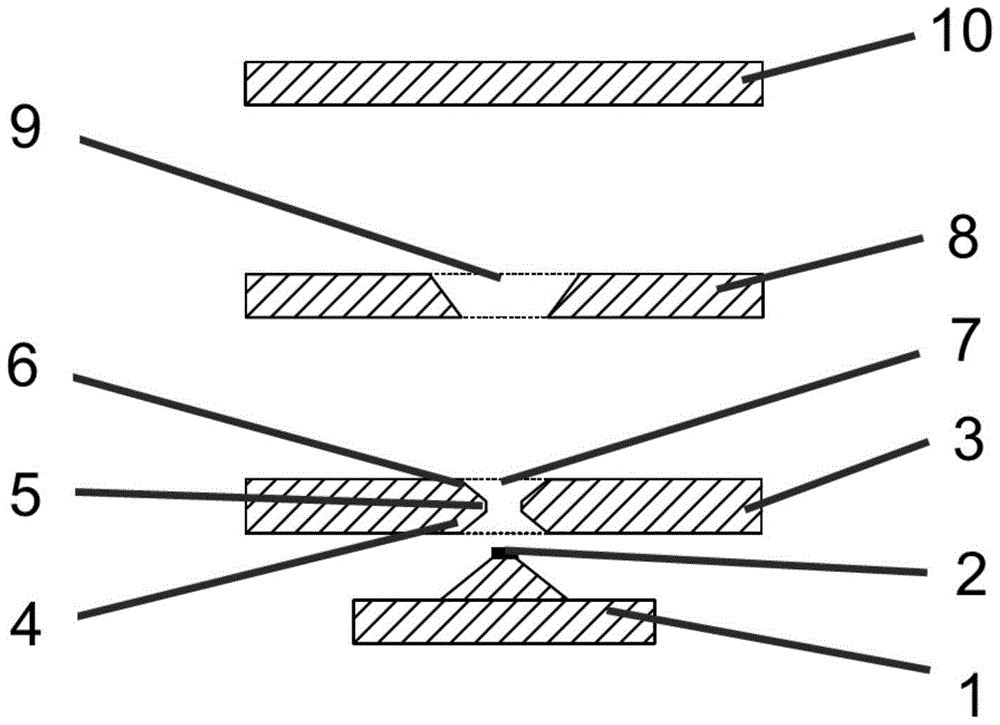

[0021] like figure 2 As shown, an electron gun of a circular planar cold cathode with a combined grid hole structure of a circular platform and a columnar structure includes a cathode, a grid 3, a first anode 8 and a second anode 10, and the cathode includes a cathode substrate 1 and is made on the cathode The field emission cathode 2 on the upper surface of the substrate 1, the gate 3 is arranged between the cathode and the first anode 8, and the gate 3 is provided with a grid hole 7 corresponding to the field emission cathode 2, and the first anode 8 Arranged between the grid 3 and the second anode 10, the first anode is provided with a first anode hole 9 corresponding to the grid 3; the position of the upper surface of the cathode substrate 1 corresponding to the grid hole 7 is provided with a conical protrusion structure, the field emission cathode 2 covers the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com