Automatic identification method for welding area of welding workpiece, computer device and computer readable storage medium

A welding area and automatic identification technology, which is applied to computer parts, calculations, welding equipment, etc., can solve the problems that cannot meet the automatic production of small batches of aluminum templates, cannot automatically calculate the welding area of welding workpieces, etc., and achieve reduction The amount of calculation of height coordinates, the effect of improving accuracy and welding quality, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

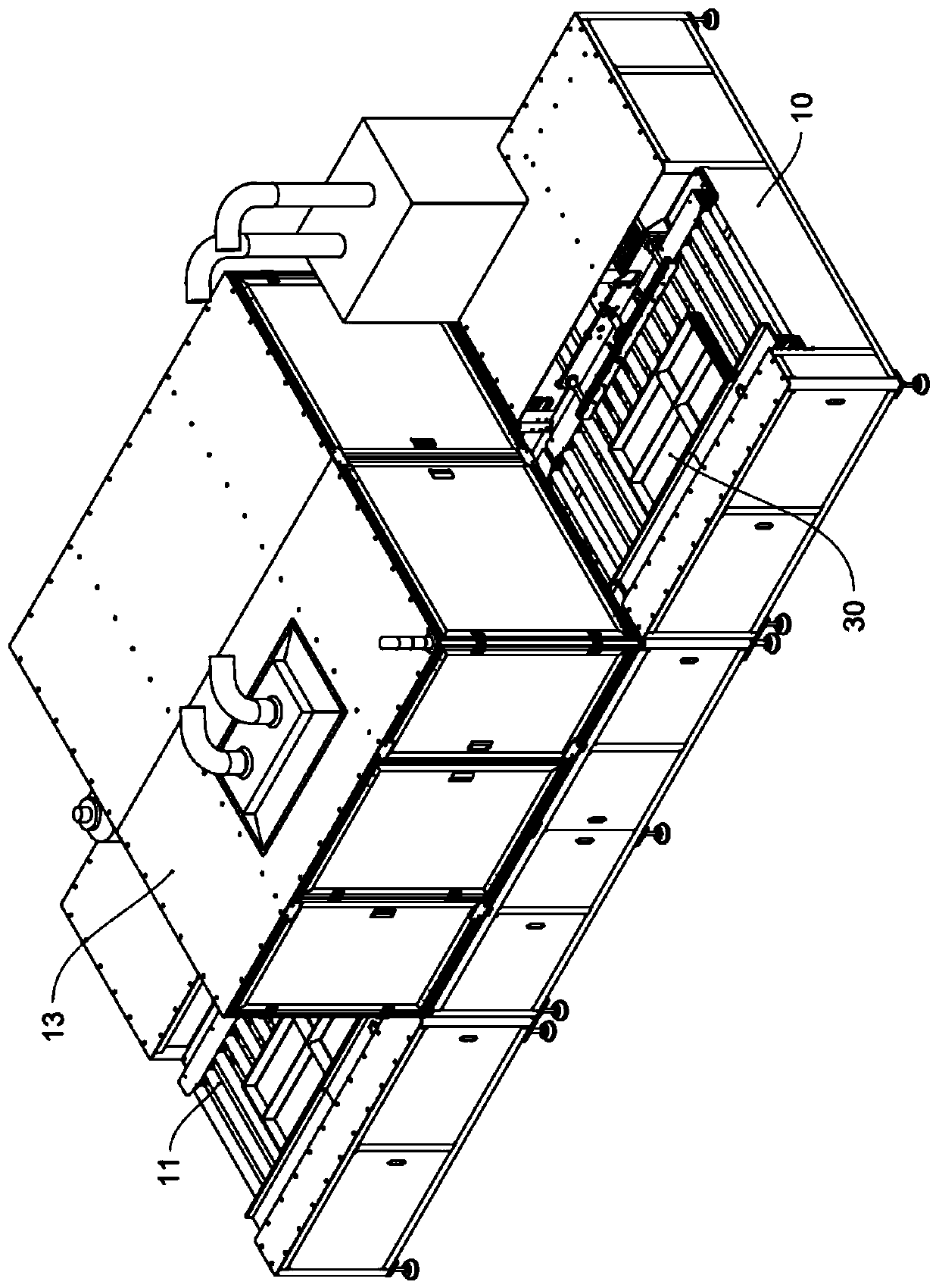

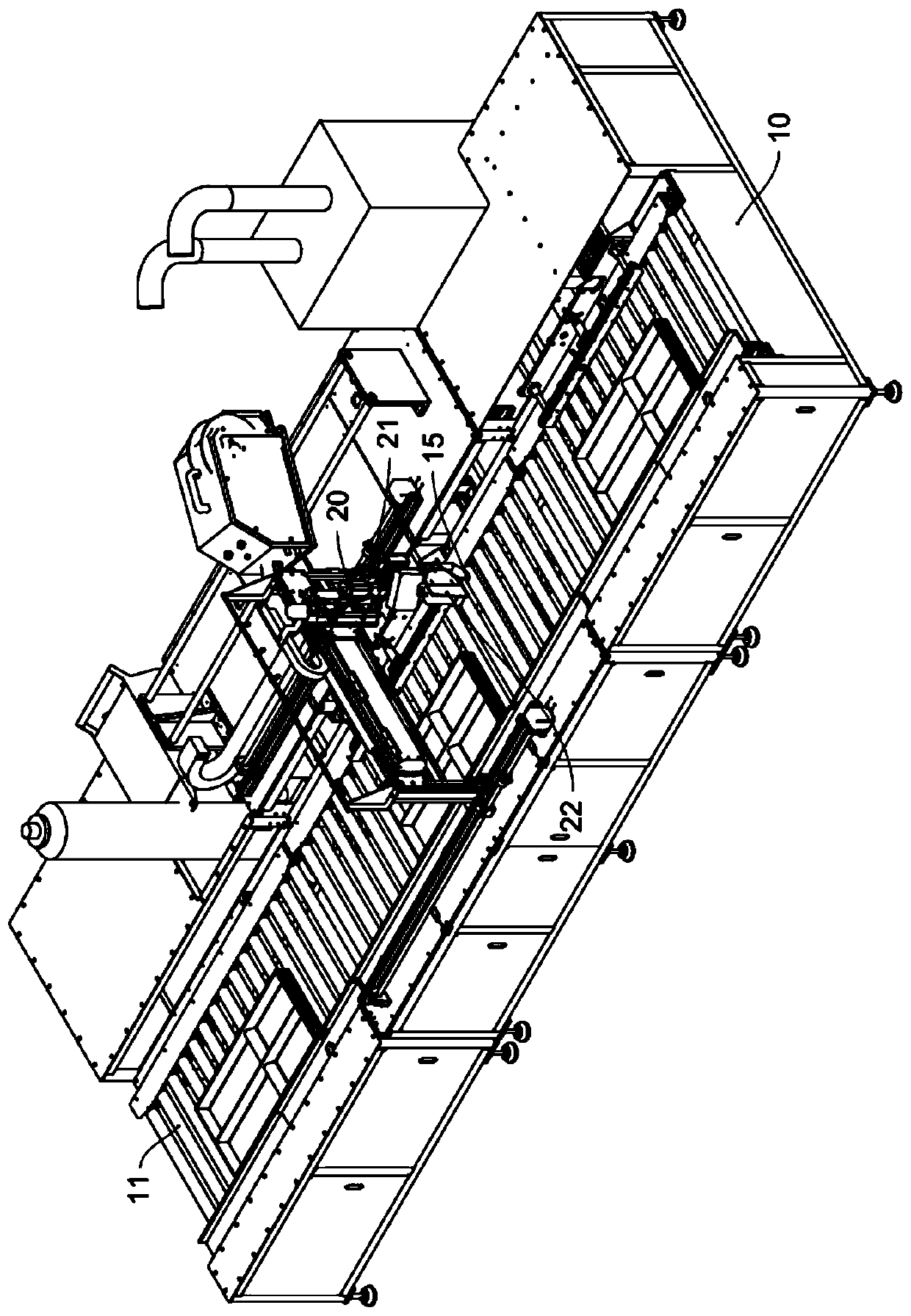

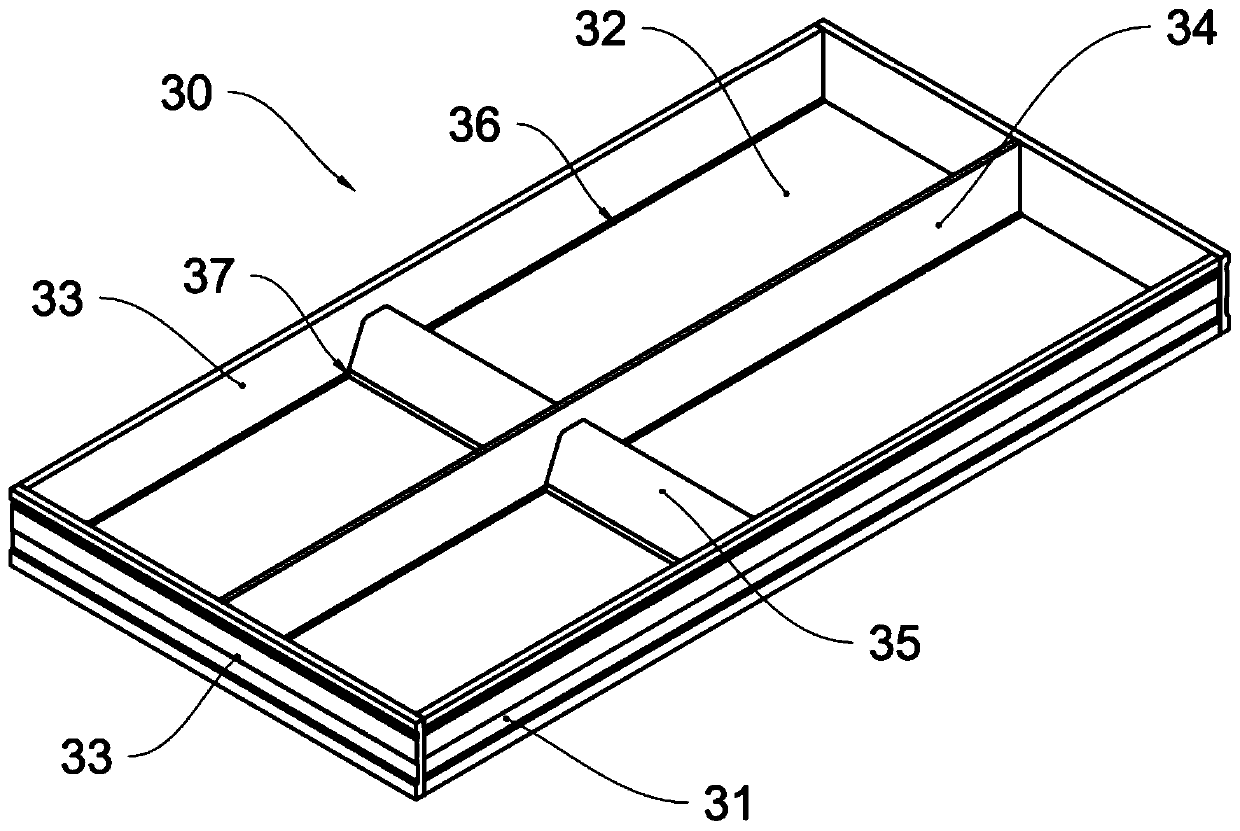

[0036] Realize the welding machine of present embodiment as figure 1 and figure 2 As shown, the welding machine has a base 10 on which a transmission assembly 11 is arranged. In this embodiment, the transmission assembly 11 includes a plurality of cylindrical rollers. Of course, the transmission assembly 11 can also be realized by using a belt or a chain. The aluminum template 30 to be welded may be placed on the transport assembly 11 . Preferably, a motor can be set to drive multiple rollers to rotate, so that the aluminum template to be welded is automatically transferred to the welding station, and is transferred to the unloading station after welding.

[0037] A welding torch 15 as a welding device is arranged above the base 10, and a casing 13 is arranged outside the welding torch 15. Preferably, a part of the casing 13 is made of a transparent material, such as acrylic, to facilitate observation from the outside The case of welding. A color camera 20 is arranged ins...

no. 2 example

[0059] Compared with the first embodiment, this embodiment adopts a depth camera that is a profile scanner, and does not need to use a seam tracker to adjust the motion trajectory of the welding gun. Compared with depth cameras, such as laser structured light cameras, binocular cameras, etc., profile scanners have higher accuracy. Usually, profile scanners calculate the height of the workpiece to be welded by emitting laser light and calculating the return time of the laser light. The profile scanner can be fixed on the base of the welding machine. Of course, the profile scanner can also be fixed on the mechanical arm or the welding gun, and follow the movement of the mechanical arm or the welding gun relative to the base. In this embodiment, since a contour scanner is used, it is not necessary to use a seam tracker to correct the motion trajectory of the welding equipment.

[0060] see Figure 5 After the workpiece to be welded is clamped and fixed, step S11 is performed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com