Spring claw, array spring claw combination plughole contact piece and electric connector

A technology of combining jacks and electrical connectors, applied in conductive connection, clamping/spring connection, connection, etc., can solve the problems of low manufacturing cost, scrapping, twisting and deformation of spring claws, etc., and achieve the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

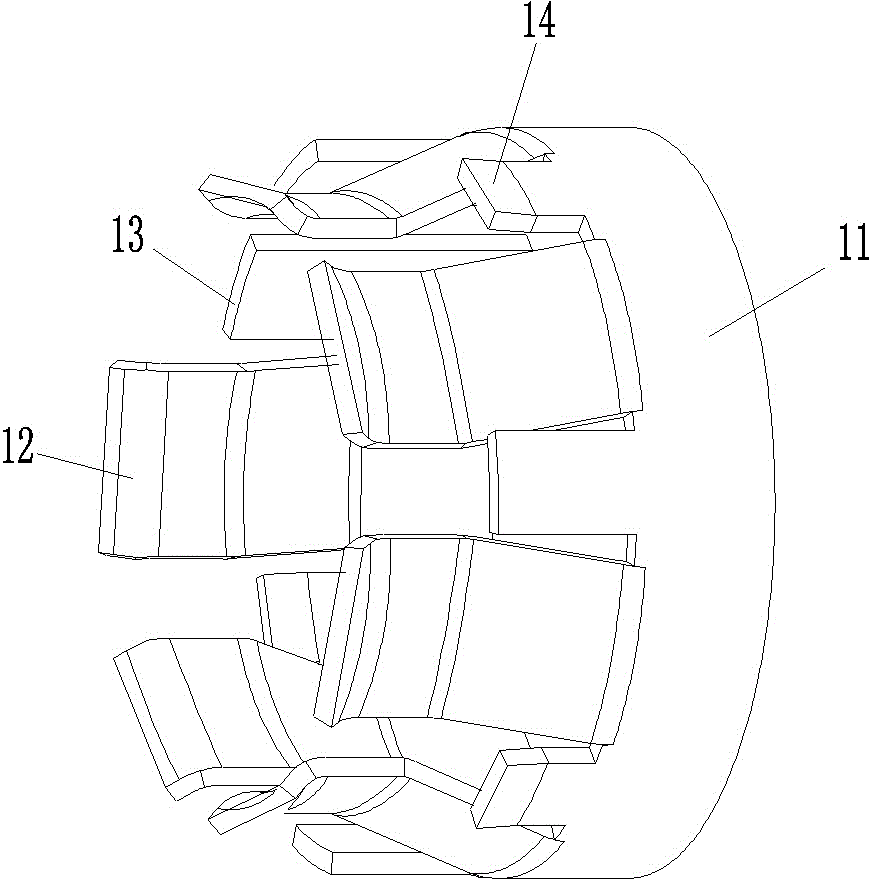

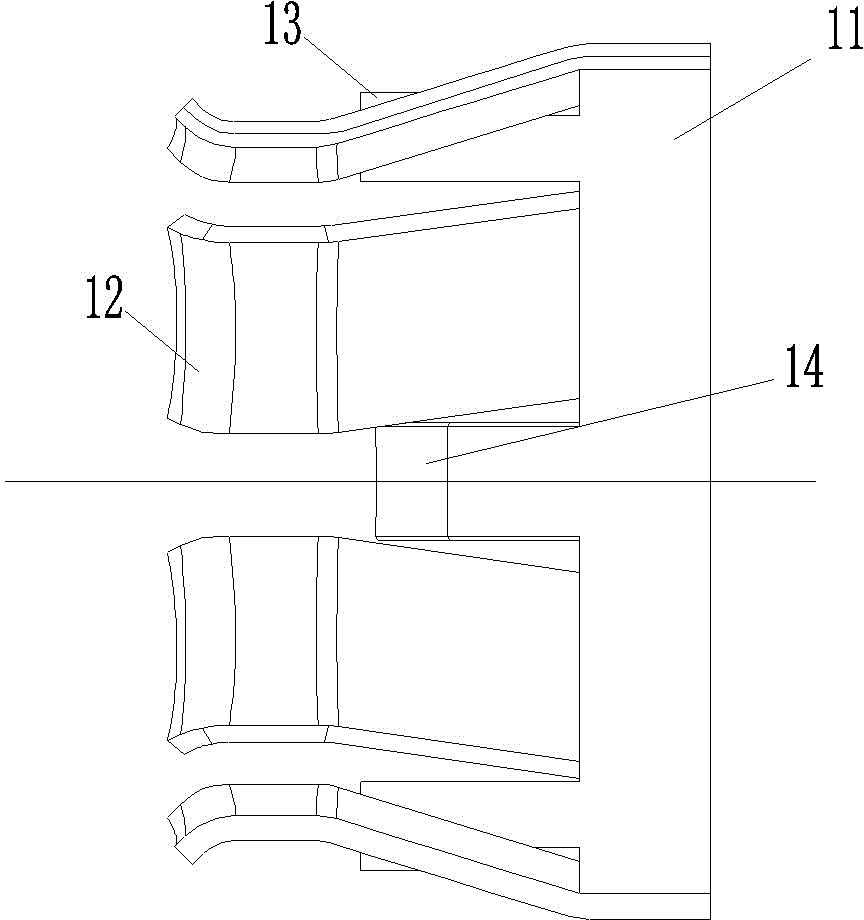

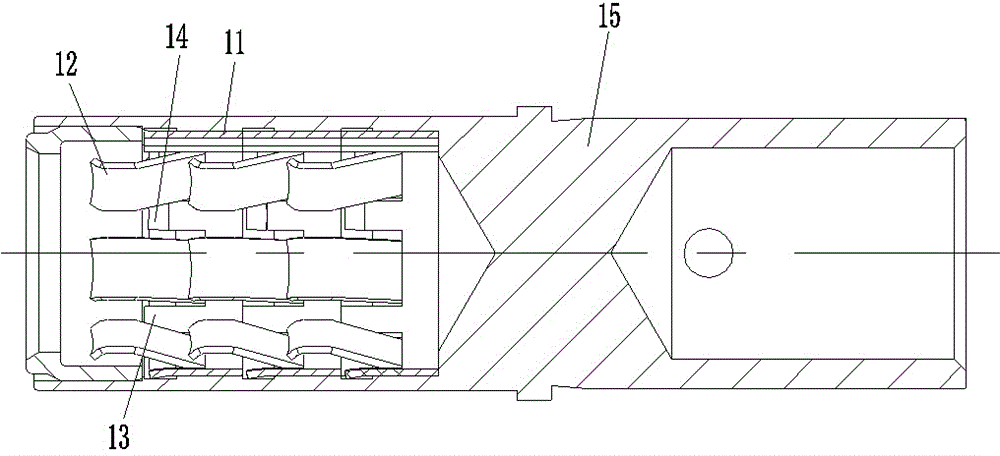

[0024] Examples of spring claws, such as Figure 1-3 As shown, the spring claw is used for the array spring claw combined socket contact, which is wound with a strip material of tin bronze material.

[0025] The spring claw includes a ring portion 11 at the rear end and a claw portion 12 located at the front end of the ring portion 11. The claw portion 12 gradually approaches the axis of the ring portion 11 from back to front. Its specific shape is the prior art and will not be described here. . Different from the prior art, in the spring claw of this embodiment, the claw portions 12 are arranged at intervals around the axis of the ring portion 11 , and a gap is left between two adjacent claw portions. In addition to the claw, the front end of the ring 11 is also provided with a support arm 13 and a thrust barb 14. The support arm 13 extends forward and forms a cantilever structure, and the thrust barb 14 also extends forward and forms a cantilever structure. The difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com