Fireproof air type bus duct

A busway and air-type technology, which is applied in the field of fire-proof air-type busway, can solve the problems of easy to be affected by moisture, decrease of insulation strength of conductive busbar, burnt busway, etc., and achieve the effect of not being easily affected by moisture and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

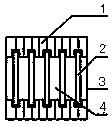

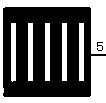

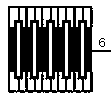

[0008] exist figure 1 Among them, 1, interphase insulation spacer of bus duct; 2, conductive bus bar; 3, heat insulation shell of bus duct; 4, hollow part of air-type bus duct. figure 2 Middle, 5, fireproof material layer. image 3 In the embodiment, the layer of fireproof material is placed behind the insulating spacer. Figure 4 In the embodiment in which the layer of fireproof material is placed in front of the insulating spacer. In this embodiment, the fireproof material layer (5) of the bus duct is placed on the conductive busbar (2) of the bus duct to seal the hollow part in the middle of the bus duct. Insert the conductive busbar (2) into the groove of the insulating spacer (1) to increase the distance between the conductive busbars, and then fasten it with the busway heat insulation shell (3). In this way, the hollow part of the bus duct forms a seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com