Waterproof photovoltaic assembly, solar roof or ceiling formed by same

A technology of photovoltaic modules and solar energy, which is applied in the direction of solar collectors, solar thermal energy, and solar thermal power generation in specific environments. It can solve the problems of difficult waterproof performance, many types of components, and complicated installation, so as to reduce electricity costs. , reduce construction costs, and increase installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

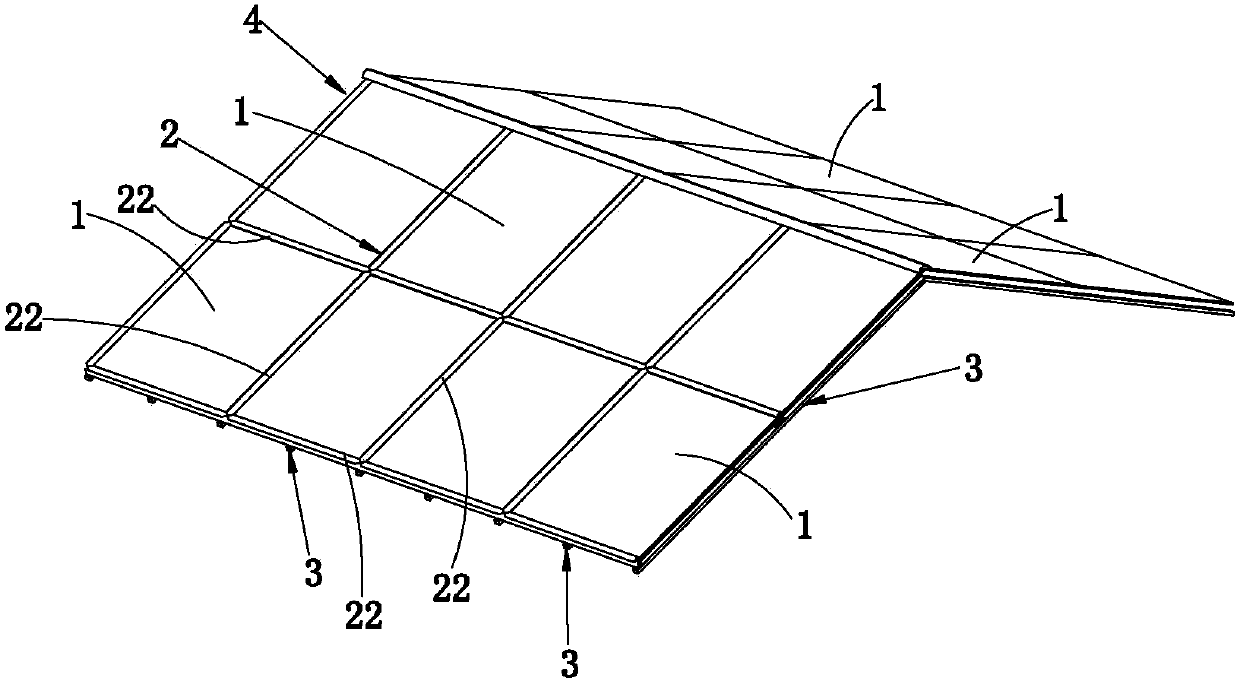

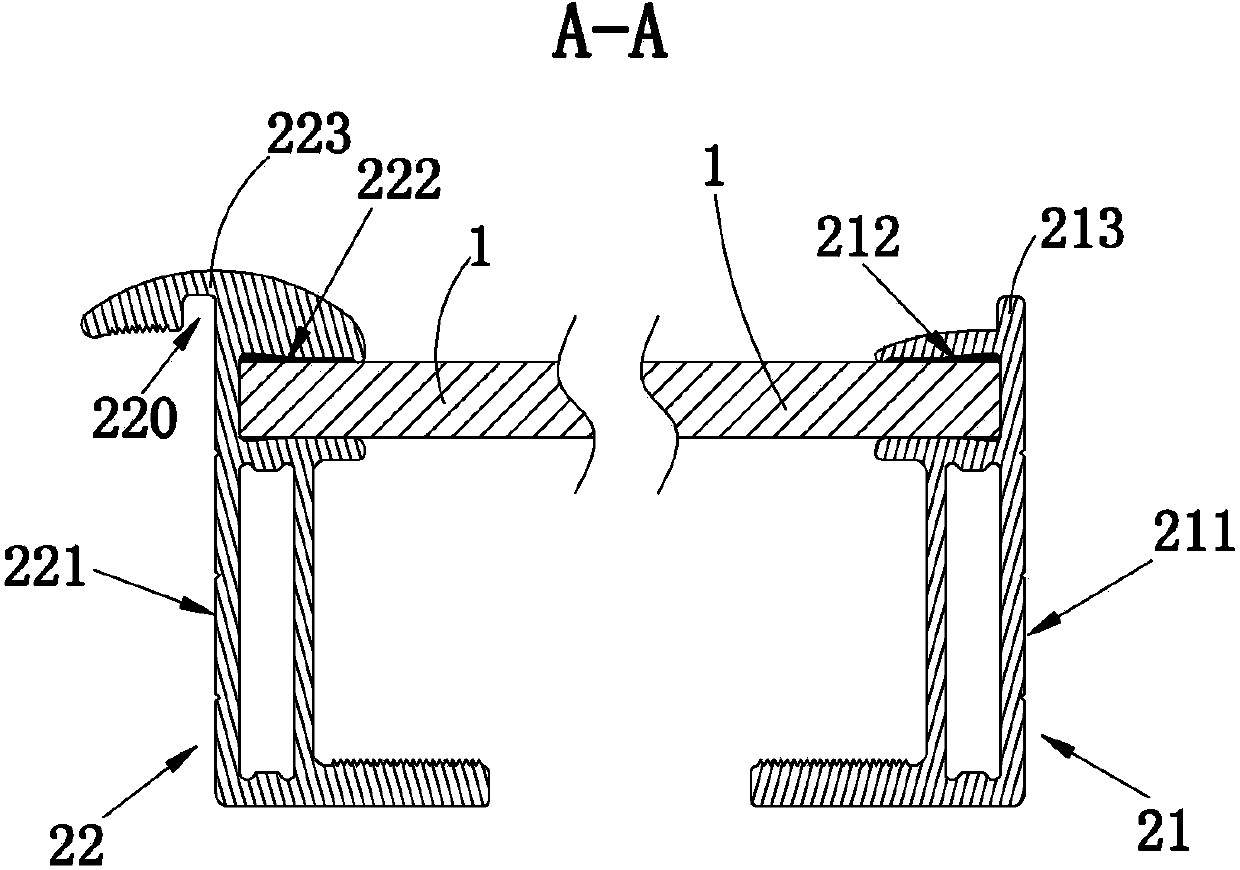

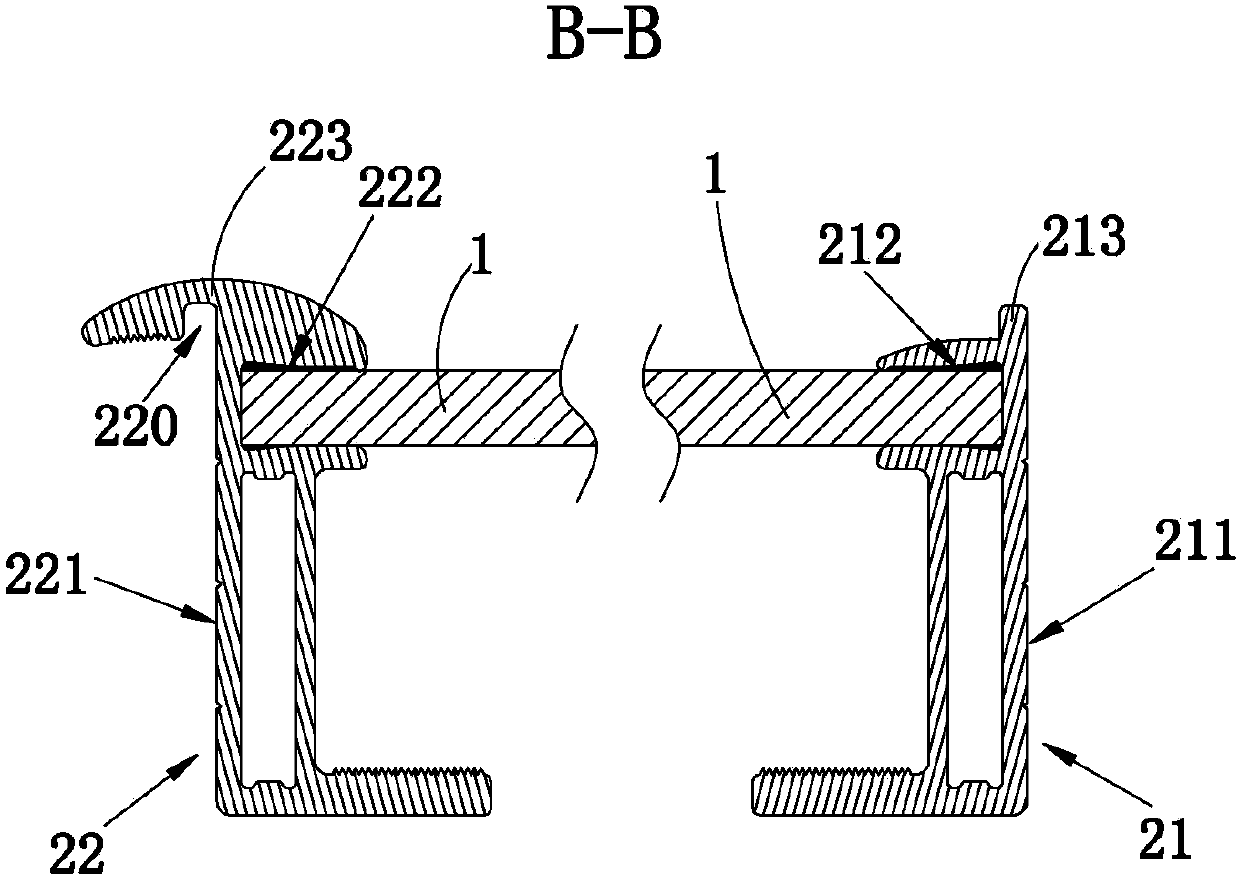

[0021] Waterproof photovoltaic modules, refer to figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , which includes a photovoltaic panel 1 and a frame body 2, the edge of the photovoltaic panel 1 is covered in the frame body 2; the frame body 2 is composed of a sub-frame bar 21 and a mother frame bar 22; the sub-frame bar 21 is composed of a first base 211 and the first installation groove 212 are integrally connected, and the first installation groove 212 is used to seal the edge of the photovoltaic panel 1; The two installation grooves 222 are used to seal the edge of the photovoltaic panel 1; the top of the first installation groove 212 is provided with a protrusion 213, and the protrusion 213 extends along the length direction of the first installation groove 212, and the top of the second installation groove 222 A cover strip 223 is provided, and the cover strip 223 is provided with a buckle groove 220 matching the protruding strip 213. In order to enhance the w...

Embodiment approach 2

[0025] The difference between this embodiment and the embodiment lies in the composition of the frame covering the edge of the photovoltaic panel. The frame of this embodiment is composed of all sub frame bars or all mother frame bars. When the waterproof photovoltaic module made of the frame of this embodiment is installed as a solar roof or roof, the other frame that is inlaid and connected with the frame composed of all sub-frame bars must be a frame composed of a full mother frame , another frame mosaic connected with the frame body made of full mother frame bars must be a frame body made of whole child frame bodies, and the two frames are connected in the manner of wooden frame body cover button frame bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com