Multi-level printing system control method based on optimum ink utilization

A technology of printing system and control method, which is applied in the direction of image communication, electrical components, etc., can solve the problems that the color characteristics of the base color cannot be considered, the ink volume utilization cannot be realized, and the screen screening process is out of touch, so as to achieve the best utilization, ensure the maximum, Guarantee the effect of color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

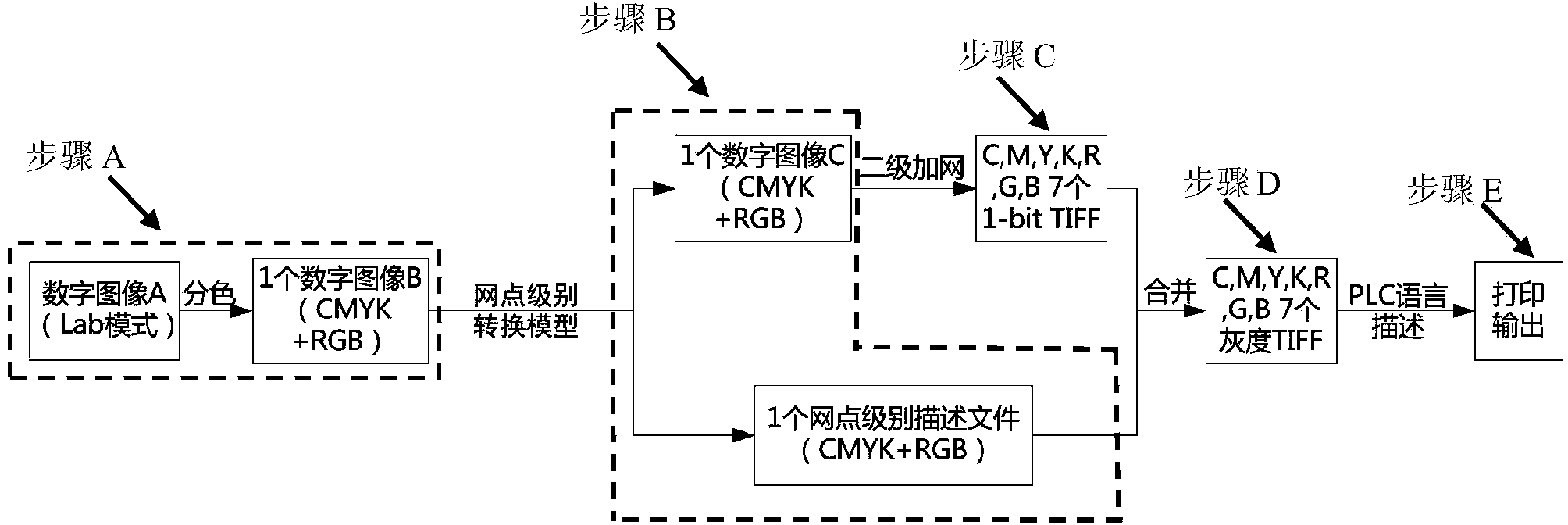

[0037] figure 2 It is a flowchart of the control of the multi-level seven-color printing system in the embodiment of the present invention.

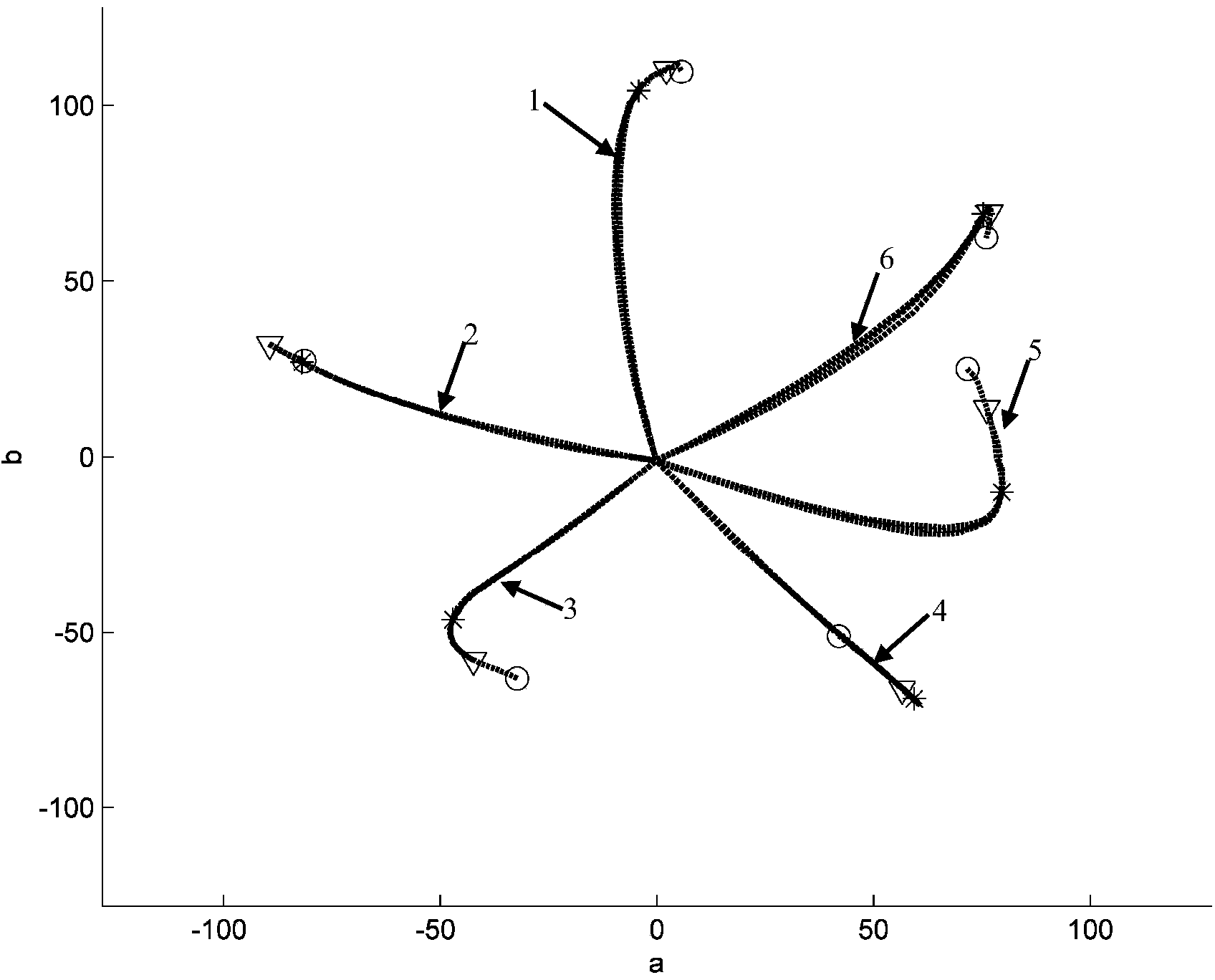

[0038] figure 2 It is a representation diagram of different levels of screen dot output levels in the ab space of the color scale in the embodiment of the present invention.

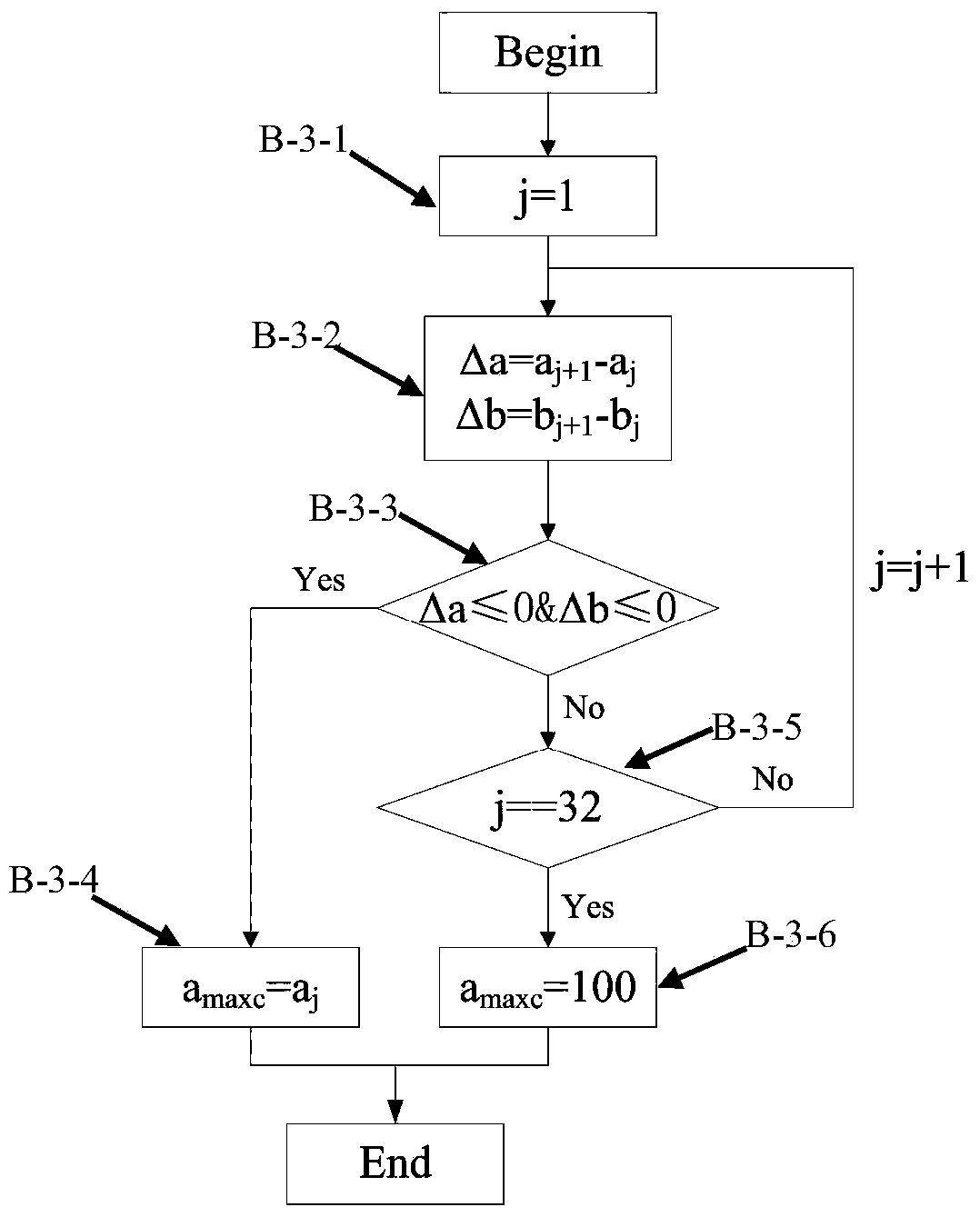

[0039] image 3 It is a flow chart of the single-channel ink volume limit algorithm in the embodiment of the present invention.

[0040] like figure 1 As shown, the multi-level seven-color printing system control has the following steps:

[0041] Step A: color-separate the chroma (Lab) image in the chroma (Lab) color space, and convert it into a second digital image in the 4+N channel color space. The number N of spot colors is determined by the hardware configuration of the printing system. In this embodiment, it is the printing color mode (CMYK+RGB), that is, 3 spot colors including RGB color mode, and a total of 7 colors are taken as an example.

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com