Extruding pulverizer driven by multiple sets of motors

A motor-driven, pulverizer technology, applied in the field of extrusion pulverizers, can solve the problems of uneven force on the shaft, affect the production efficiency of the factory, and consume manpower and material resources, so as to improve the efficiency of restoring production and save manpower and material resources Cost, size and weight reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

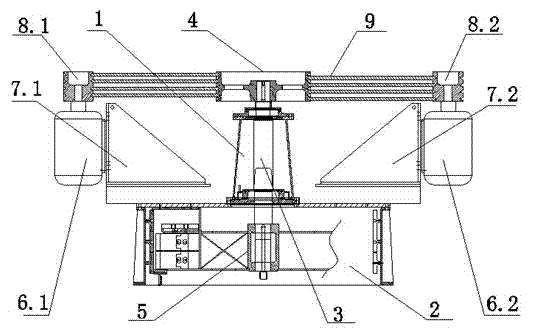

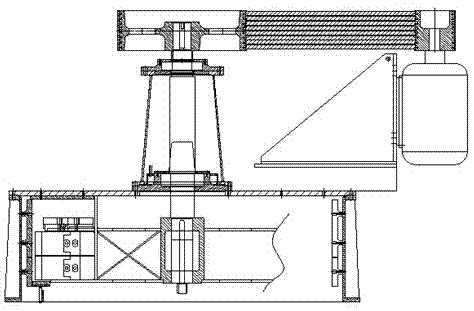

[0013] refer to figure 1 The extrusion pulverizer driven by multiple sets of motors shown includes a body 1 and a crushing chamber 2 connected to the bottom of the body 1. The body 1 is pierced with a main shaft 3 extending into the crushing chamber 2. The body 1 The upper and lower ends of the main shaft 3 are respectively provided with an upper bearing 3.1 and a lower bearing 3.2. The upper end of the main shaft 3 is connected with a large pulley 4, and the lower end of the main shaft 3 is connected with a rotor 5 for crushing mineral materials. The crushing chamber 2 is equipped with the motor mount 7.1 of installing left motor 6.1 and the motor mount 7.2 of installing right motor 6.2 symmetrically with main shaft 3 on 2, the power of left motor 6.1 and right motor 6.2 is 150 kilowatts, and all rotates along the same direction, left The shaft upper end of motor 6.1 and right motor 6.2 is respectively connected with left belt pulley 8.1 and right belt pulley 8.2, links to e...

Embodiment 2

[0015] As the second embodiment of the present invention, no drawings are provided, and its basic structure is the same as that of Embodiment 1, the difference is that there are four motor racks on the crushing chamber, each of which is equipped with a motor rack with the same power and steering. The four motors are arranged in a cross shape with the main shaft as the center, and the large pulleys are respectively connected to the four small pulleys through staggered belt transmissions. The power of the four motors is equivalent to the power of the original large motor, which is enough to support the normal operation of the extrusion pulverizer. At the same time, they are arranged in a cross shape, and act together on the main shaft from four directions to ensure that the main shaft is evenly stressed and will not be biased. It is also more convenient to disassemble and repair.

Embodiment 3

[0017] As the third embodiment of the present invention, no drawings are provided, and its basic structure is the same as that of Embodiment 1, the difference is that three motor frames are arranged on the crushing cavity, and a motor with the same power and steering is installed on each of them. , the three motors are arranged in an equilateral triangle with the main shaft as the center, and the large pulleys are respectively connected to the three small pulleys through staggered belt transmission. The power of the three motors is equivalent to the power of the original large motor, which is enough to support the normal operation of the extrusion pulverizer. At the same time, the arrangement of the equilateral triangle makes the spindle evenly loaded and more stable and reliable, and it is also more convenient to disassemble and repair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com