Grinding wheel for profiling edging machine

A technology of edging wheel and profiling grinding, which is applied in the direction of machine tools, grinding machines, grinding/polishing equipment, etc. suitable for grinding the edge of workpieces, and can solve the problems of short service life of sandpaper, increased processing costs, and reduced work efficiency. Achieve the effect of not easy to wear, improve service life and reduce processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

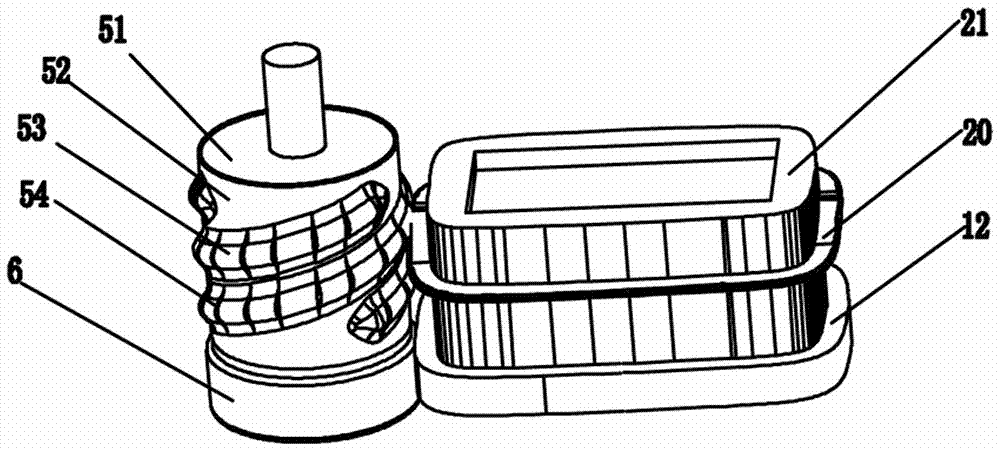

[0032] Embodiment one, see image 3 and Figure 4 Shown, the first embodiment of the edging wheel 5 used on the above-mentioned profiling edging machine is: it comprises the edging wheel body 51 and sandpaper 52, the edging wheel body 51 is a cylinder made of soft material, and the sandpaper 52 Be arranged on the outer surface of the edging wheel body 51, the outer surface of the sandpaper 52 extends out the edging protrusion 53, the edging protrusion 53 is provided with an opening 54, and the opening 54 is a vertically arranged slit, so that the edging protrusion The edging protrusion 53 is elastic; the edging protrusion 53 extends from bottom to top along the circumferential direction of the surface of the sandpaper 52 in a spiral shape, and several vertical openings 54 are arranged on the spiral edging protrusion 53 at a certain interval.

[0033] Wherein, the cross-section of the edging protrusion 53 is a convex arc shape with a high center and low sides.

[0034] The ed...

Embodiment 2

[0037] Embodiment two, such as Figure 5 As shown, this embodiment is similar to the edging wheel of the first embodiment above, and the only difference is that the edging protrusion 53 extends along the circumferential direction of the surface of the sandpaper 52 in a ring shape, and the ring-shaped edging protrusion Several openings 54 are arranged on the 53 at certain intervals.

[0038] In addition, in order to further meet different usage requirements, the surface of the sandpaper 52 may be provided with the above-mentioned several annular edging protrusions 53 , and each annular edging protrusion 53 is parallel to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com