Screen printing film and surface modification method of the same

A technology of surface modification and screen printing, applied in the preparation of printing surface, screen printing machine, printing, etc., can solve the problems of intolerance, difficult to improve printing quality, change of line width, etc., to improve the quality of screen printing , the effect of reducing production costs

Inactive Publication Date: 2015-02-04

IND TECH RES INST

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

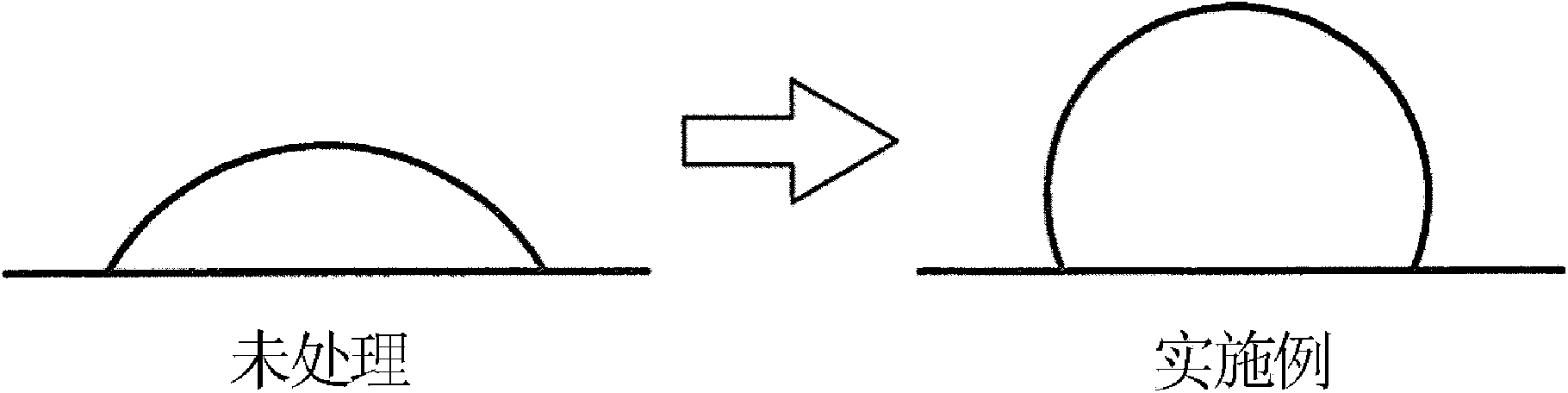

After swelling, the tension of the screen printing film will decrease and it will not be durable, and the line width will change or be uneven, so it is difficult to improve the printing quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

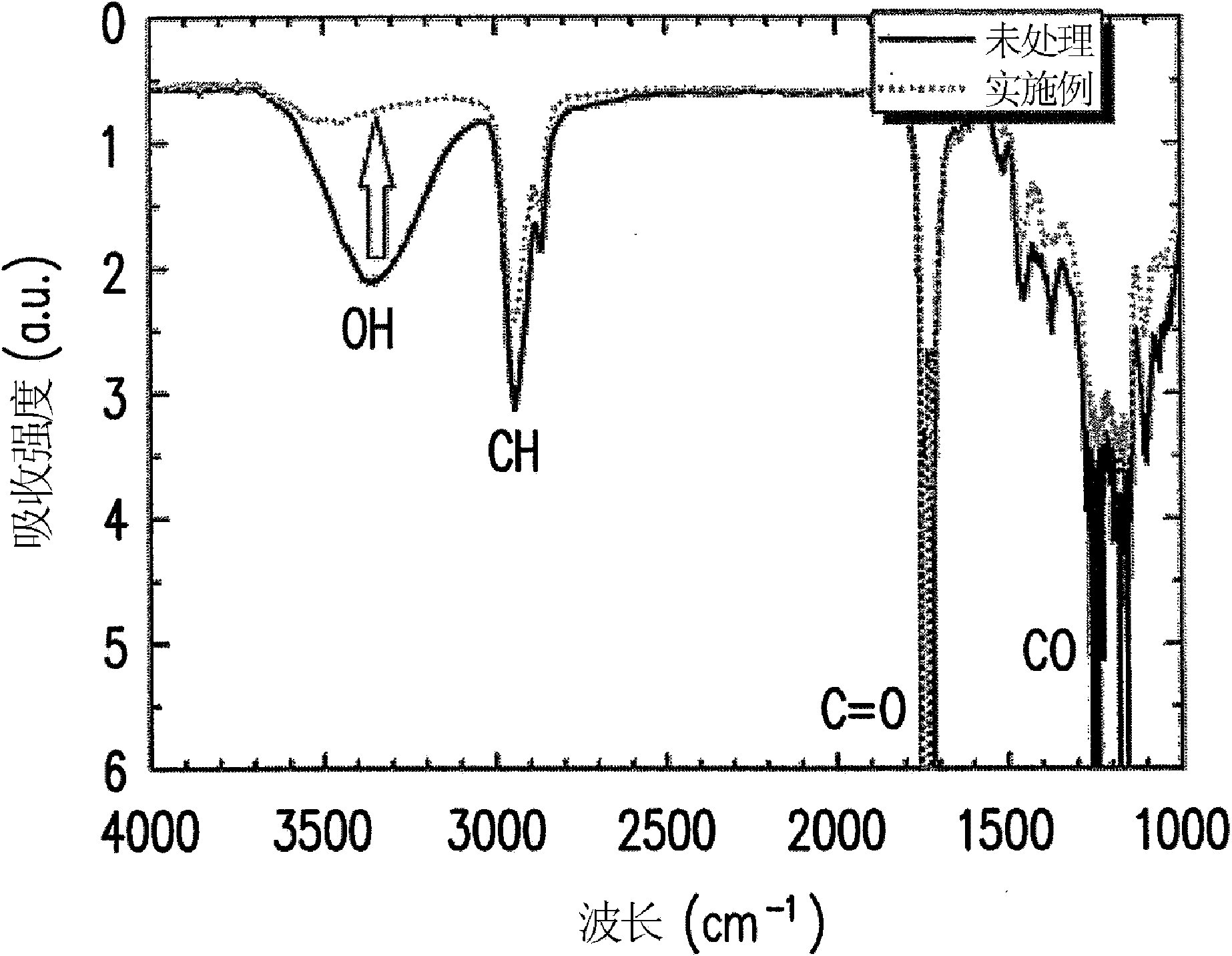

[0039] First of all, edge glue masking frame protection is carried out, and the screen printing film used is Al / PTFE plate with PVA film in it. Then, the PVA film is irradiated 4 to 5 times for about 2.5 seconds each time by using an infrared lamp heating source, wherein the power of each infrared lamp is 1300W.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

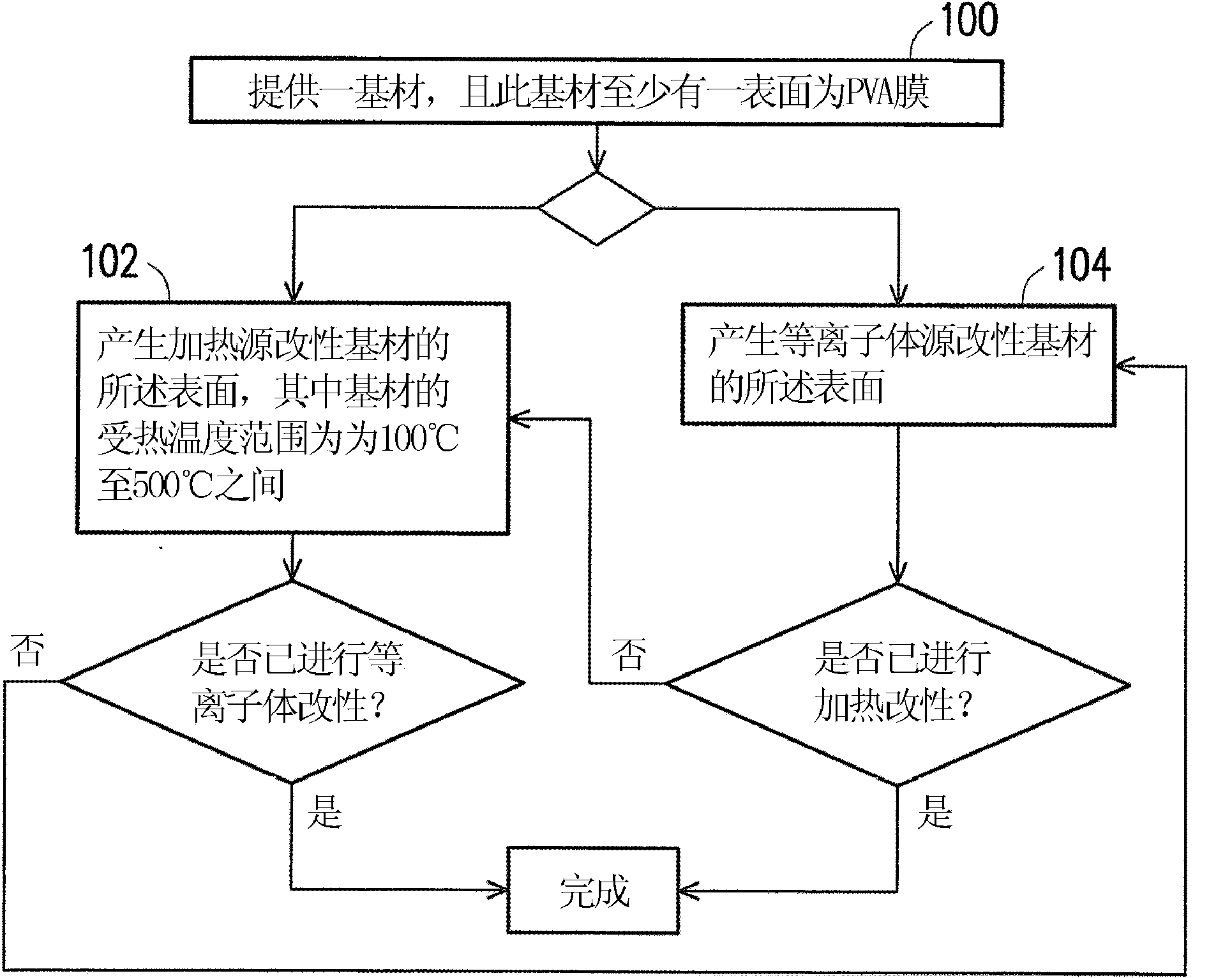

A screen printing film and a surface modification method of the same are provided. The method includes providing a substrate having a PVA film on at least one surface of the substrate. The surface of the substrate is modified by generating a heating source and a plasma source, wherein a heating temperature to the substrate is between 100° C. and 500° C. The step of generating the heating source may be prior to, after, or simultaneous with the step of generating the plasma source.

Description

technical field [0001] The invention relates to a screen printing device, and in particular to a screen printing film and a surface modification method thereof. Background technique [0002] Due to technological progress, precision screen printing has become the main manufacturing technology for printing electrode silver wires on solar cells or solar panels. The screen-printed film is the printed mask that defines the pattern of the electrode lines. After attaching it to the solar panel to be printed and applying a paste containing a conductive metal, usually silver, the electrode printing can be completed. The screen printing film can be reused after scraping off the residual paste until the surface paste is difficult to scrape off or the film itself is damaged. [0003] The screen printing film can be made of polymer film or metal film, the latter provides good mechanical strength and high reusability, but is quite expensive to manufacture. The polymer film is low in co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B41N3/03B41F15/36

CPCC23C16/46C23C16/0209B41N1/247C23C16/50C23C16/482C23C16/481C23C16/32C23C16/27B41C1/14C23C16/26B05D5/083B05D7/04B05D1/62Y10T428/31855

Inventor 林育霆黄昆平张志振

Owner IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com