A device for desulfurization and hydrogen production by electrolysis of coal-water slurry

A hydrogen production device and electrolyzed water technology, which is applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of complicated process and device, difficulty in popularization, high cost, etc., to overcome incomplete reaction and save time and resources , fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

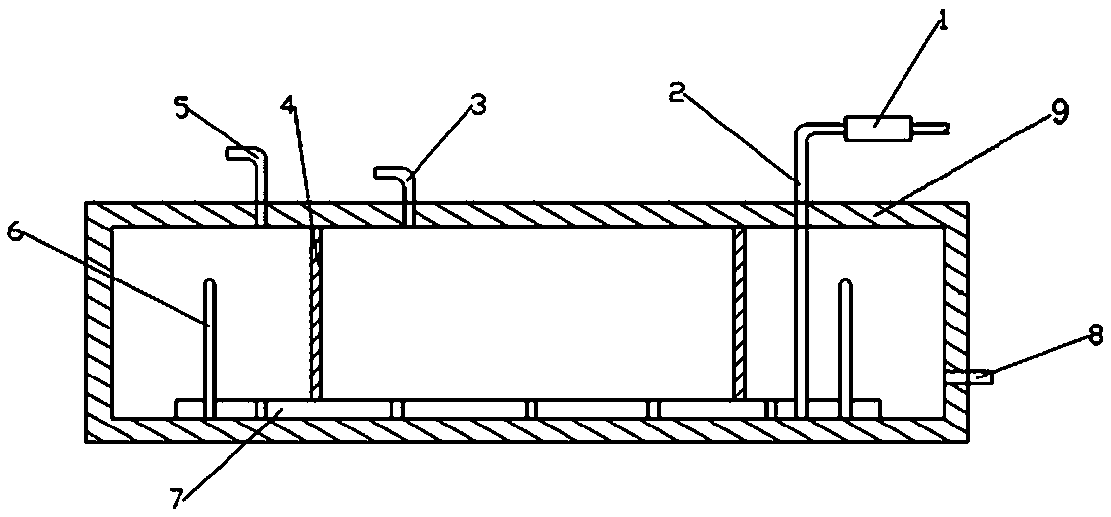

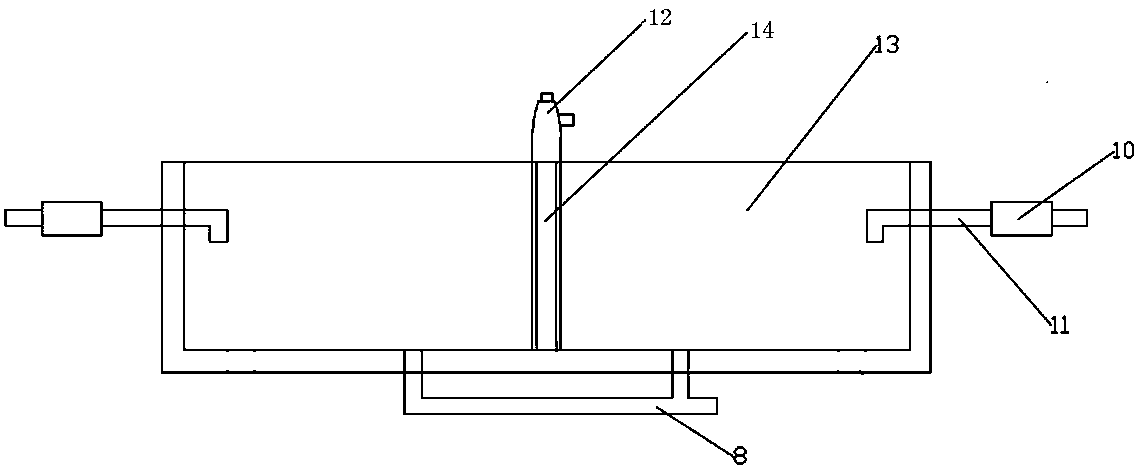

[0019] The batching system includes a hopper feeder, a microwave dryer, a belt conveyor, a mill, a batching hopper, a dry powder mixer, and a slurry mixer; there are multiple belt conveyors, and the hopper feeder and microwave dryer are installed in Above the belt conveyor I, the mill is installed below the outlet of the belt conveyor I; at the outlet of the mill is equipped with a belt conveyor II, and the batching hopper is installed below the outlet of the belt conveyor II; an automatic weighing is installed below the batching hopper Belt conveyor, automatic weighing belt conveyor is equipped with a dry powder mixer under the outlet, slurry mixer is installed under the dry powder mixer, and above the slurry mixer is equipped with a water supply pipe and an electrolyte recovery pipe; the electrolysis system agitating box is two connected together without capping The solution tank 13, the slurry mixer outlet to the top of the two solution tanks are equipped with a liquid infusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com