Steel plate for Ni-Mo low-temperature high-ductility X100 pipe fittings and manufacturing method thereof

A high-toughness, steel plate technology, applied in the field of steel plate manufacturing, can solve the problems of low steel plate strength, large strength value drop, and low steel pass rate, so as to improve production efficiency and yield, increase yield and pass rate, and relax Effect of heat treatment process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

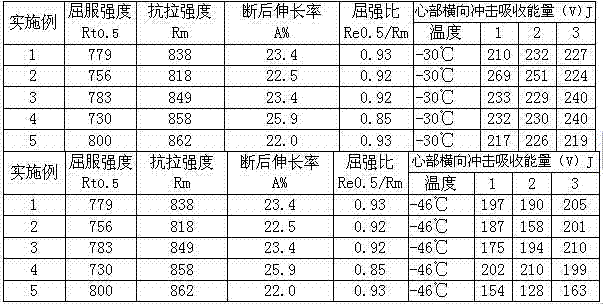

Examples

Embodiment 1

[0033] The thickness of the steel plate for X100 pipe fittings involved in this example is 45mm, and its chemical composition is calculated by mass percentage: C: 0.12%, Mn: 1.5%, Si: 0.3%, S: 0.0015%, P: 0.01%, Nb: 0.04%, Ti: 0.018%, V: 0.08%, Alt: 0.03%, N: ≤0.010%, O: ≤0.006%, Mo: 0.40~0.50%, Cu: ≤0.35%, Ni: 0.51~0.65%, Cr: ≤0.35%, Ca: ≤0.01%, Ceq=0.52, Pcm=0.24 and the rest are Fe and unavoidable impurities.

[0034] The manufacturing process of the 45mm-thick X100 steel plate for pipe fittings is to configure the smelting raw materials according to the chemical composition of the above-mentioned finished steel plate, and then sequentially carry out KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain molten steel with high purity. Afterwards, the continuous casting slab with a thickness of 370mm is continuously cast by the continuous casting machine; the continuous casting slab is heated to 1180°C for two-stage rolling: the first...

Embodiment 2

[0038] The thickness of the steel plate for X100 pipe fittings involved in this example is 55mm, and its chemical composition is calculated by mass percentage: C: 0.09%, Mn: 1.8%, Si: 0.25%, S: 0.0015%, P: 0.01%, Nb: 0.065%, Ti: 0.018%, V: 0.04%, Alt: 0.028%, N: ≤0.010%, O: ≤0.006%, Mo: 0.40~0.50%, Cu: ≤0.35%, Ni: 0.51~0.65%, Cr: ≤0.35%, Ca: ≤0.01%, Ceq=0.55, Pcm=0.27, the rest is Fe and unavoidable impurities.

[0039] The manufacturing process of the 55mm-thick X100 steel plate for pipe fittings is to configure the smelting raw materials according to the chemical composition of the above-mentioned finished steel plate, and then sequentially perform KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain molten steel with high purity. Afterwards, the continuous casting slab with a thickness of 370mm is continuously cast by the continuous casting machine; the continuous casting slab is heated to 1175°C for two-stage rolling: the first st...

Embodiment 3

[0043] The thickness of the steel plate for X100 pipe fittings involved in this example is 38mm, and its chemical composition is calculated by mass percentage: C: 0.11%, Mn: 1.6%, Si: 0.2%, S: 0.0015%, P: 0.01%, Nb: 0.055%, Ti: 0.018%, V: 0.07%, Alt: 0.03%, N: ≤0.010%, O: ≤0.006%, Mo: 0.40~0.50%, Cu: ≤0.35%, Ni: 0.51~0.65%, Cr: ≤0.35%, Ca: ≤0.01%, where Ceq=0.50, Pcm=0.23, and the rest are Fe and unavoidable impurities.

[0044] The manufacturing process of the 38mm-thick X100 steel plate for pipe fittings is to configure the smelting raw materials according to the chemical composition of the above-mentioned finished steel plate, and then sequentially carry out KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain molten steel with high purity. Afterwards, the continuous casting slab with a thickness of 370mm is continuously cast by the continuous casting machine; the continuous casting slab is heated to 1183°C for two-stage rolling: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com