Bearing roller unbalanced magnetron sputtering ion plating device and bearing roller unbalanced magnetron sputtering ion plating method

A magnetron sputtering and bearing roller technology, which is applied in the field of bearing roller manufacturing, can solve the problems of small friction coefficient and wear rate, large friction coefficient and wear rate, poor vibration accuracy and wear resistance, etc., and achieve friction coefficient and Low wear rate, high vibration accuracy and wear resistance, and improved performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

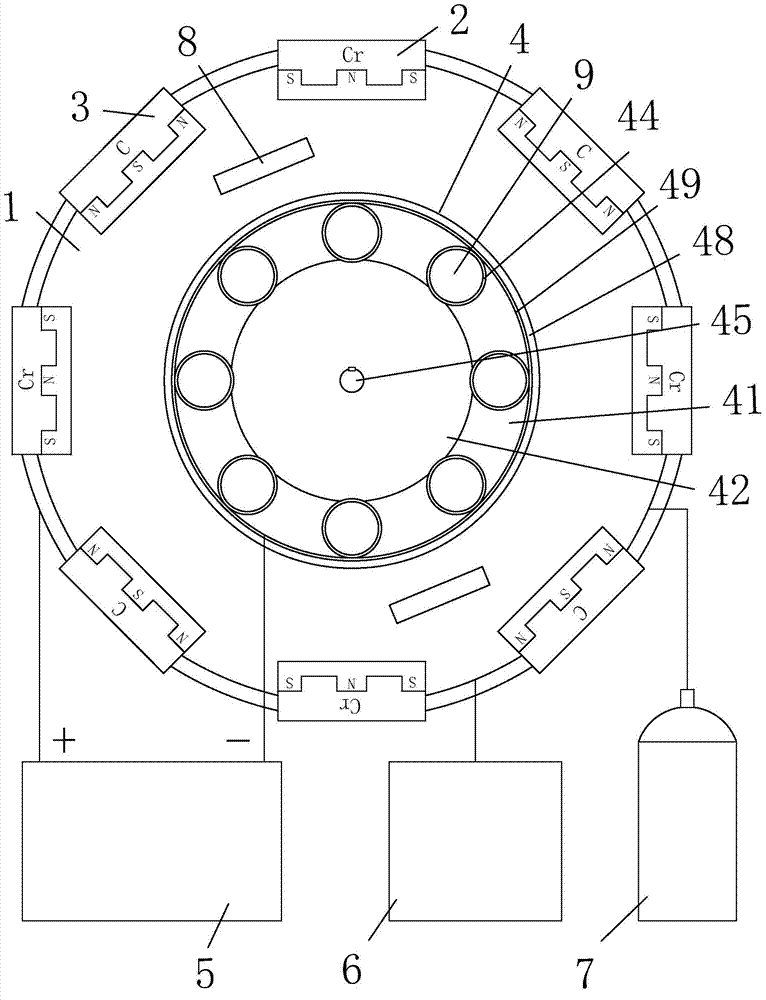

[0020] as attached figure 1 , attached figure 2 Shown: a bearing roller unbalanced magnetron sputtering ion plating device, including a vacuum chamber 1, a workpiece support turntable 4 located in the vacuum chamber 1, four pairs of chromium targets 2 alternately placed on the periphery of the workpiece support turntable 4 and pairs of Four pairs of carbon targets 3 whose number is the same as that of chromium targets 2, a bias power supply 5, a vacuum device 6 communicated with the vacuum chamber 1, a working gas bottle 7 and a heater 8. Both the chromium target 2 and the carbon target 3 have a purity of 99.99%. There are two heaters 8 located at the bottom of the vacuum chamber 1; the heaters 8 are electric heaters.

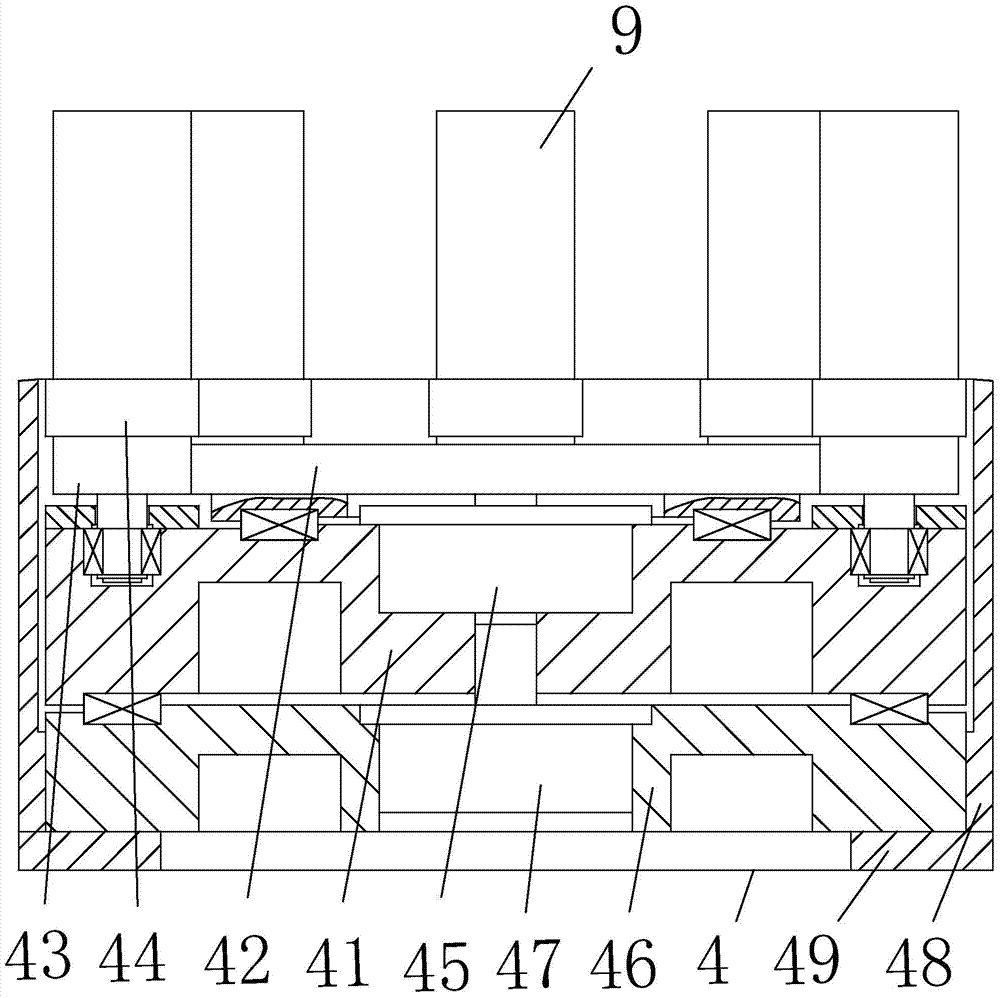

[0021]The workpiece support turntable 4 includes a support seat 41, a driving gear 42 pivotally connected to the upper end of the support seat 41 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com