Silver and chrome-based electric contact self-lubricating composite material and preparation method thereof

A composite material and electrical contact technology, which is applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve the problems of no related reports, etc., and achieve the effects of strong operability, no pollution to the environment, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

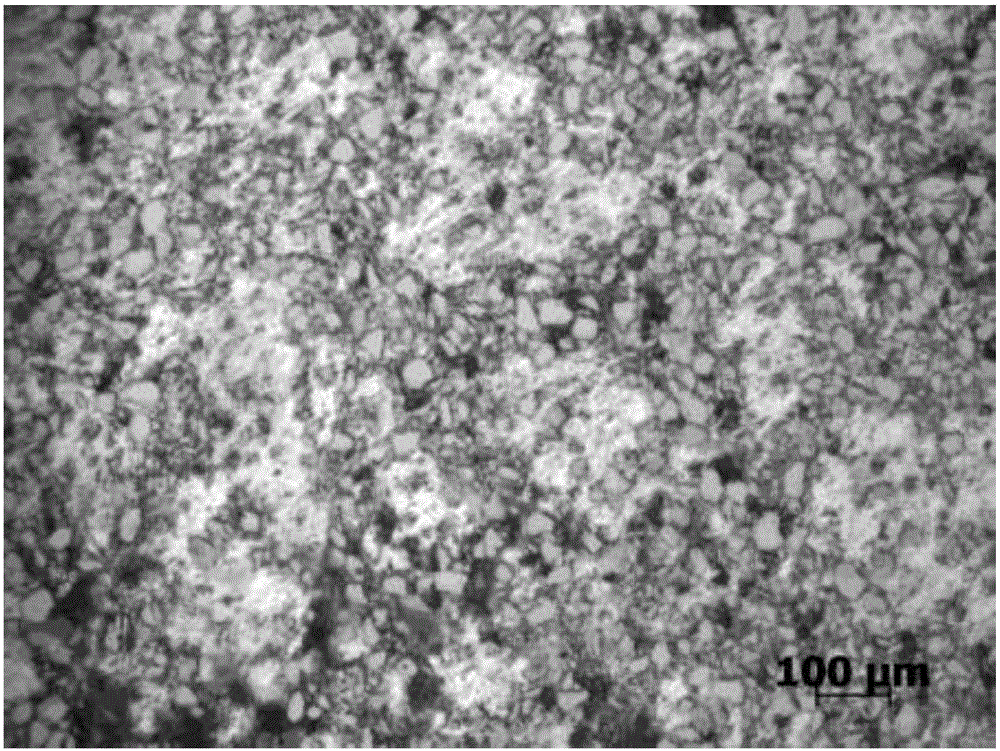

[0034] A silver-chromium-based electrical contact self-lubricating composite material, comprising 55% by mass of silver, 15% by mass of chromium, and 30% by mass of niobium diselenide. Its preparation method comprises the following steps:

[0035] S1, nano niobium diselenide (NbSe 2 ) powder added to 0.4mol / L silver nitrate (AgNO 3 ) in the solution for ultrasonic dispersion for 1 h, put it into an oven for drying; put the dried powder into Al 2 o 3 In the burning boat, put it into a high-temperature diffusion furnace with H2 and heat it to 200 ° C for 1 hour to prepare silver-coated nano-niobium diselenide;

[0036] S2, mixing silver powder, chromium powder, and silver-coated nano-niobium diselenide prepared in step S1 according to the mass percentage ratio to prepare a mixed material;

[0037] S3, the above-mentioned mixed materials and stainless steel balls are proportioned according to the mass ratio of 1:10, sealed and placed in the stainless steel ball mill tank of t...

Embodiment 2

[0043] A silver-chromium-based electrical contact self-lubricating composite material, comprising 60% by mass of silver, 15% by mass of chromium, and 25% by mass of niobium diselenide. Its preparation method comprises the following steps:

[0044] S1, nano niobium diselenide (NbSe 2 ) powder added to 0.4mol / L silver nitrate (AgNO 3 ) in the solution for ultrasonic dispersion for 1 h, put it into an oven for drying; put the dried powder into Al2 o 3 In the burning boat, put it into a high-temperature diffusion furnace with H2 and heat it to 200 ° C for 1 hour to prepare silver-coated nano-niobium diselenide;

[0045] S2, mixing silver powder, chromium powder, and silver-coated nano-niobium diselenide prepared in step S1 according to the mass percentage ratio to prepare a mixed material;

[0046] S3, the above-mentioned mixed materials and stainless steel balls are proportioned according to the mass ratio of 1:10, sealed and placed in the stainless steel ball mill tank of the...

Embodiment 3

[0052] A silver-chromium-based electrical contact self-lubricating composite material, comprising 65% by mass of silver, 20% by mass of chromium, and 15% by mass of niobium diselenide. Its preparation method comprises the following steps:

[0053] S1, nano niobium diselenide (NbSe 2 ) powder added to 0.4mol / L silver nitrate (AgNO 3 ) in the solution for ultrasonic dispersion for 1 h, put it into an oven for drying; put the dried powder into Al 2 o 3 In the burning boat, put it into a high-temperature diffusion furnace with H2 and heat it to 200 ° C for 1 hour to prepare silver-coated nano-niobium diselenide;

[0054] S2, mixing silver powder, chromium powder, and silver-coated nano-niobium diselenide prepared in step S1 according to the mass percentage ratio to prepare a mixed material;

[0055] S3, the above-mentioned mixed materials and stainless steel balls are proportioned according to the mass ratio of 1:10, sealed and placed in the stainless steel ball mill tank of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com