Preparation method and application of oleic acid-modified copper sulphide nano-material

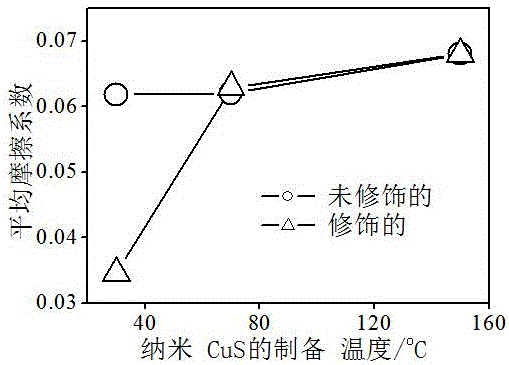

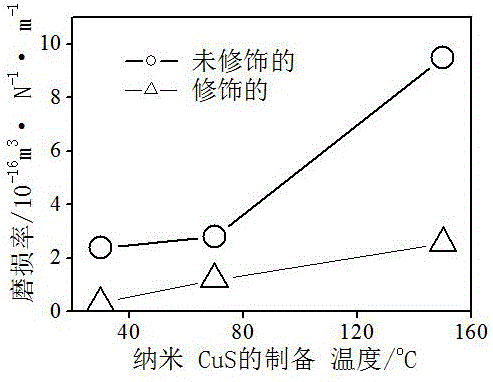

A nano-material and oleic acid modification technology, applied in the field of friction, can solve the problems of complicated preparation method and low effect of oleic acid modified CuS, achieve the effects of reducing friction coefficient and wear rate, improving friction and wear performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

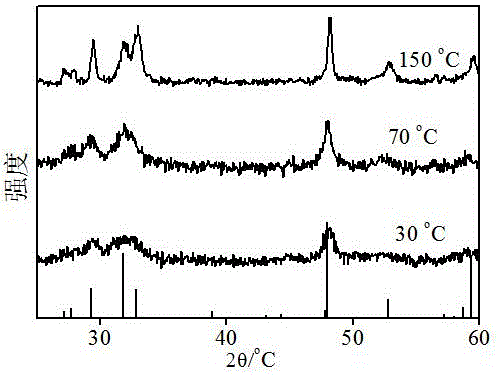

Embodiment 1

[0024] A preparation method of copper sulfide nanomaterial modified by oleic acid, specifically comprising the following steps:

[0025] (1) Weigh 0.015 moles of C 2 h 5 Dissolve NS in 70mL of water, then accurately measure 10ml of oleic acid in the thioacetamide solution, and stir evenly to obtain a mixed solution of thioacetamide and oleic acid;

[0026] (2) Weigh 0.01 moles of Cu(CH 3 COO) 2 ·H 2 O was dissolved in 70mL water to obtain copper acetate solution;

[0027] (3) In a water bath at 30°C, drop the copper acetate solution obtained in step (2) into the mixed solution of thioacetamide and oleic acid obtained in step (1), and stir for 10 hours;

[0028] (4) After the reaction, cool to room temperature, filter and dry, and collect the oleic acid-modified CuS nanomaterials.

Embodiment 2

[0030] A preparation method of copper sulfide nanomaterial modified by oleic acid, specifically comprising the following steps:

[0031] (1) Weigh 0.015 moles of C 2 h 5 Dissolve NS in 70mL of water, then accurately measure 10ml of oleic acid in the thioacetamide solution, and stir evenly to obtain a mixed solution of thioacetamide and oleic acid;

[0032] (2) Weigh 0.01 moles of Cu(CH 3 COO) 2 ·H 2 O was dissolved in 70mL water to obtain copper acetate solution;

[0033] (3) In a 70°C water bath, drop the copper acetate solution obtained in step (2) into the mixed solution of thioacetamide and oleic acid obtained in step (1), and stir for 10 hours;

[0034] (4) After the reaction, cool to room temperature, filter and dry, and collect the oleic acid-modified CuS nanomaterials.

Embodiment 3

[0036] (1) Weigh 0.015 moles of C 2 h 5 Dissolve NS in 70mL water to form a thioacetamide solution, then accurately measure 10ml of oleic acid in the thioacetamide solution, and stir evenly to obtain a mixed solution of thioacetamide and oleic acid;

[0037] (2) Weigh 0.01 moles of Cu(CH 3 COO) 2 ·H 2 O was dissolved in 70mL water to obtain copper acetate solution;

[0038] (3) Put the copper acetate solution in step (2) dropwise into the mixed solution of thioacetamide and oleic acid obtained in step (1), and after magnetic stirring for 10 minutes, divide the solution into two parts and transfer them into two 100ml In the reaction kettle, heat at 150°C for 10 hours;

[0039] (4) After the reaction, cool down to room temperature, filter and dry the reaction solution obtained in the two reaction kettles, and collect the oleic acid-modified CuS nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com