Special side-sliding pressing pin for pattern machine

A technology of pattern machine and presser foot, which is applied in the direction of floral stitch sewing machine, cloth pressing mechanism, sewing machine components, etc., can solve the problems that the presser foot template cannot be kept stable, the lifting mechanism is heavy and other problems, achieve good sewing effect, reduce Process, the effect of improving sewing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

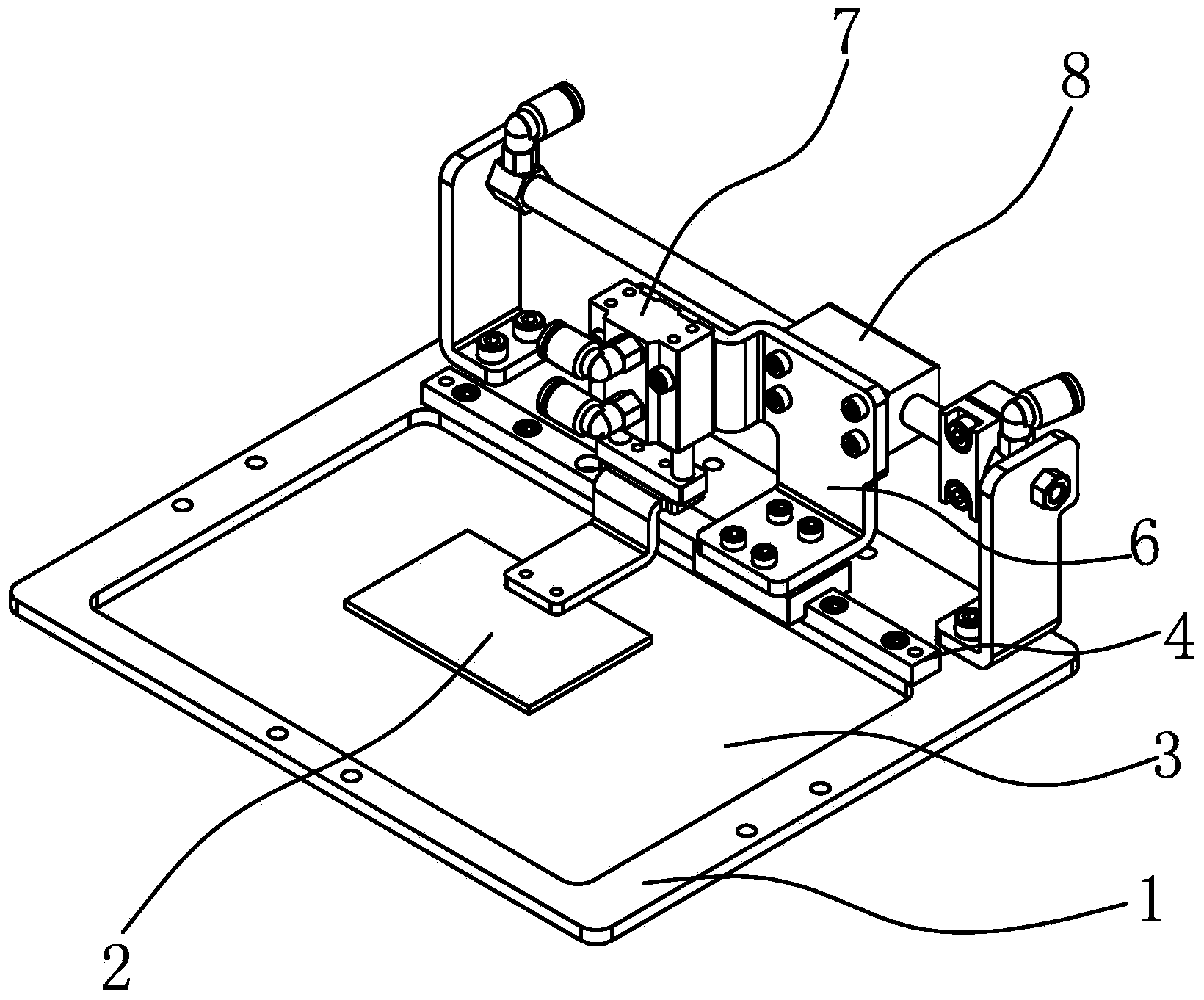

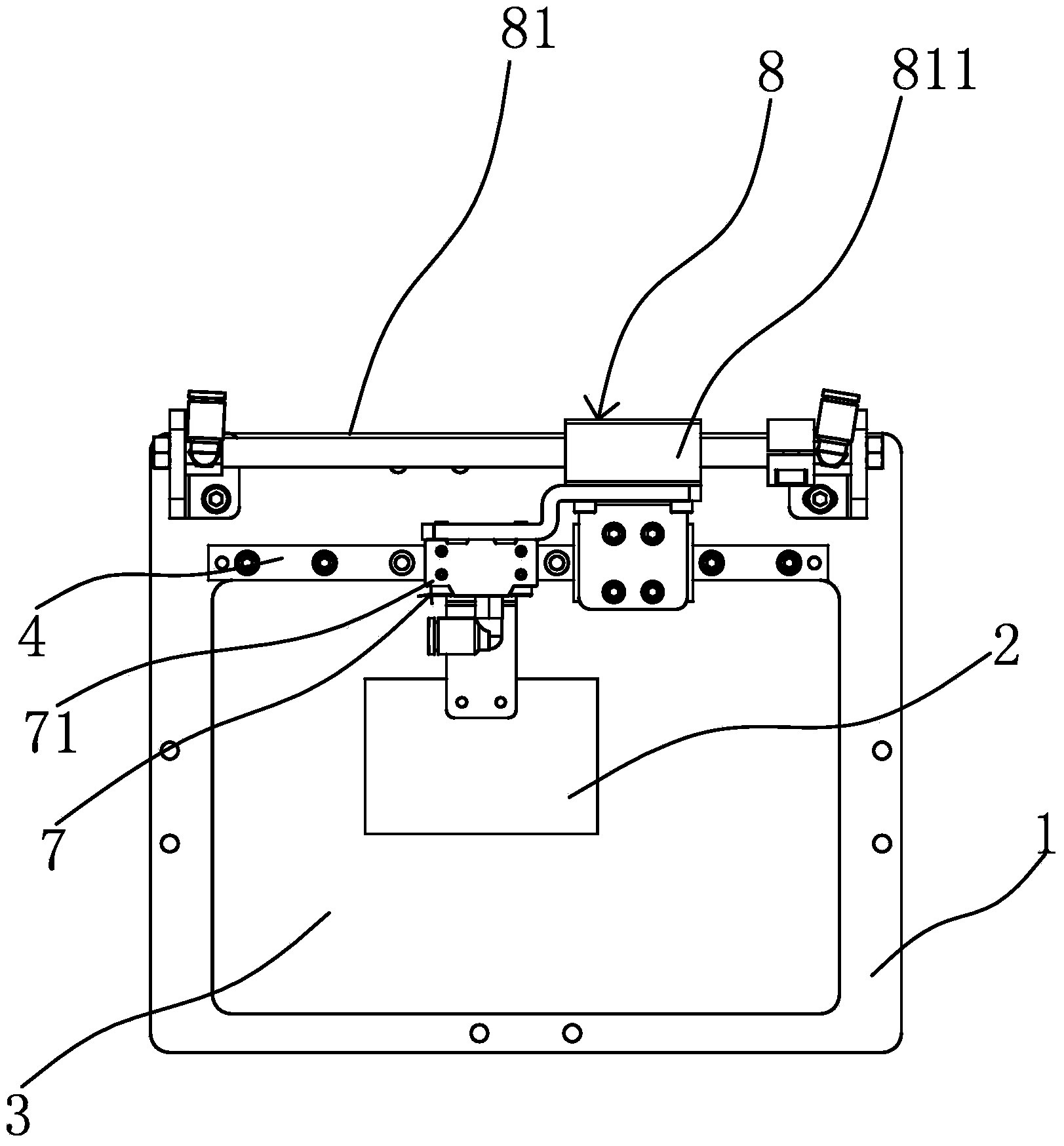

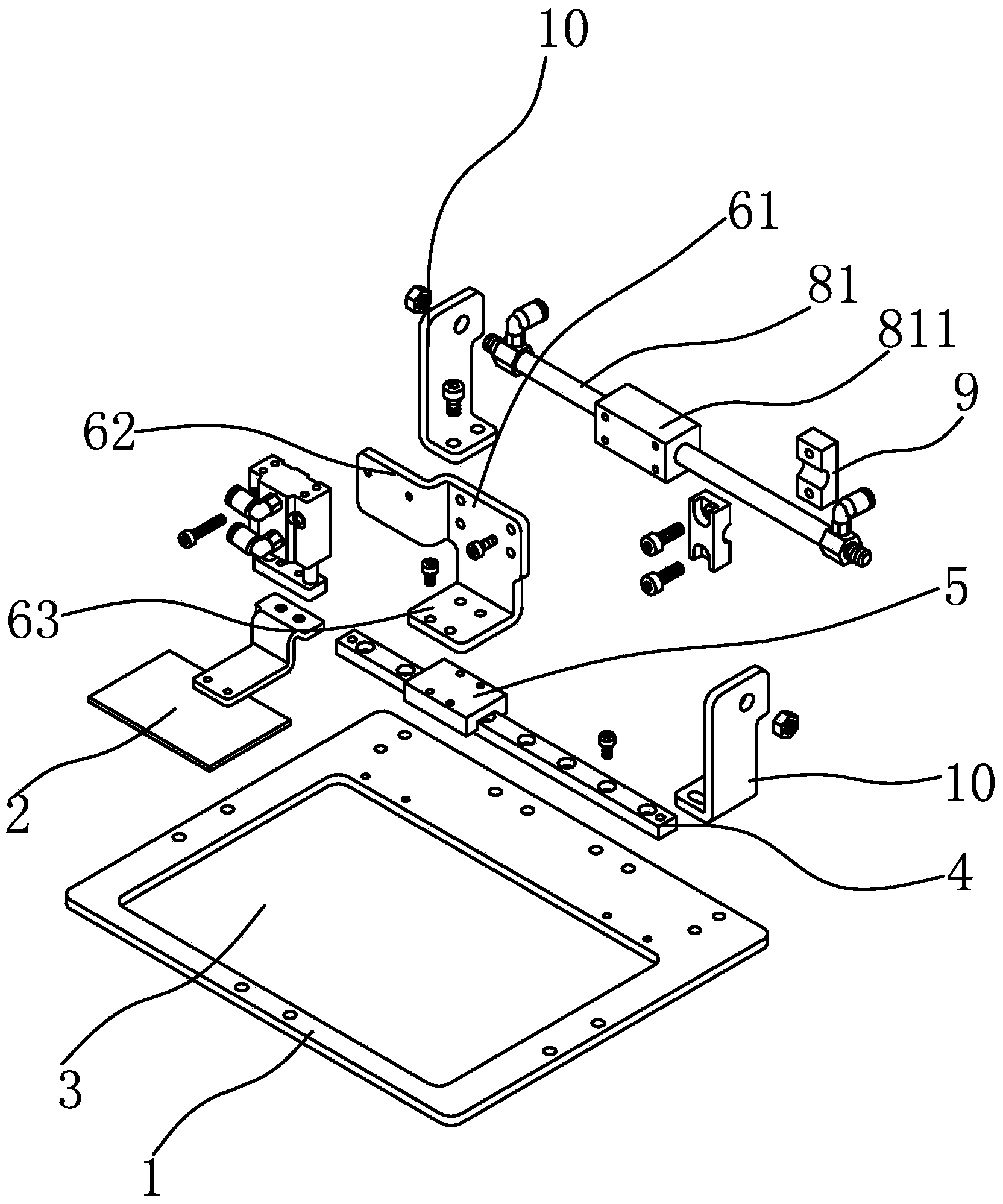

[0025] Such as figure 1 , figure 2 and image 3 As shown, the side-slip special presser foot includes a presser frame 1 and a presser template 2, the presser frame 1 is square, the middle part of the presser frame 1 has a square working through hole 3, and one side of the presser frame 1 is along the side The length direction is fixedly provided with a slide rail 4, the slide rail 4 is slidably connected with a connecting plate 6, and the connecting plate 6 is fixedly provided with a lifting mechanism 7 capable of driving the binder template 2 to move up and down. The lifting mechanism 7 includes a cylinder 71, and the cylinder 71 Fixed on the connecting plate 6 with the piston rod facing down, the pressing template 2 is screwed with the piston rod of the cylinder 71, the pressing template 2 is connected with the lifting mechanism 7, and the pressing template 2 can extend into the pressing frame 1 In the area of the operation through hole 3, the pressing template 2 moves ...

Embodiment 2

[0031] This embodiment is substantially the same as Embodiment 1, the difference is that the driving member 8 in this embodiment includes a lead screw and a screw nut, the screw nut is screwed on the lead screw, the connecting plate 6 is fixedly connected with the screw nut, and the lead screw It is connected with a motor that can drive it to rotate, and the motor rotates forward and reversely to drive the lead screw to rotate, and the movement of the screw nut is driven by the thread to change the position of the pressing template 2 to achieve the same purpose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com