Mechanical driver for fixed-diameter orifice pipelines

A mechanical drive, sizing hole technology, applied in mechanical equipment, special pipes, pipe components, etc., can solve the problems of no special design and the way of walking is not stable enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

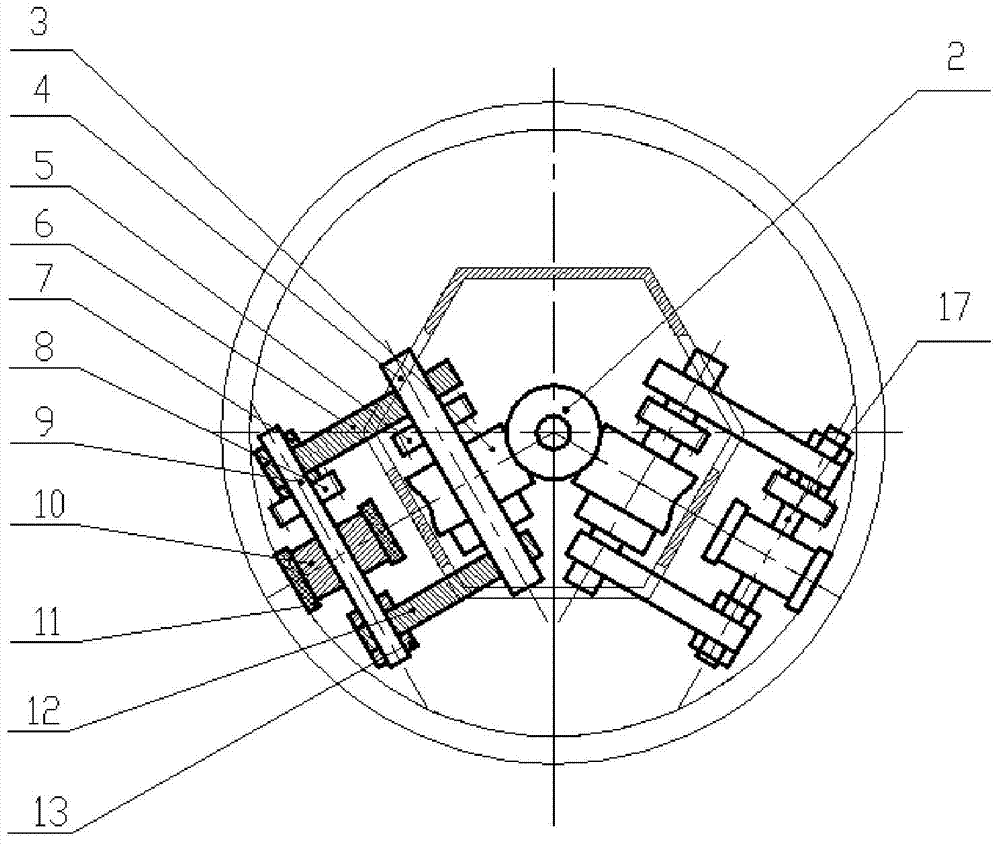

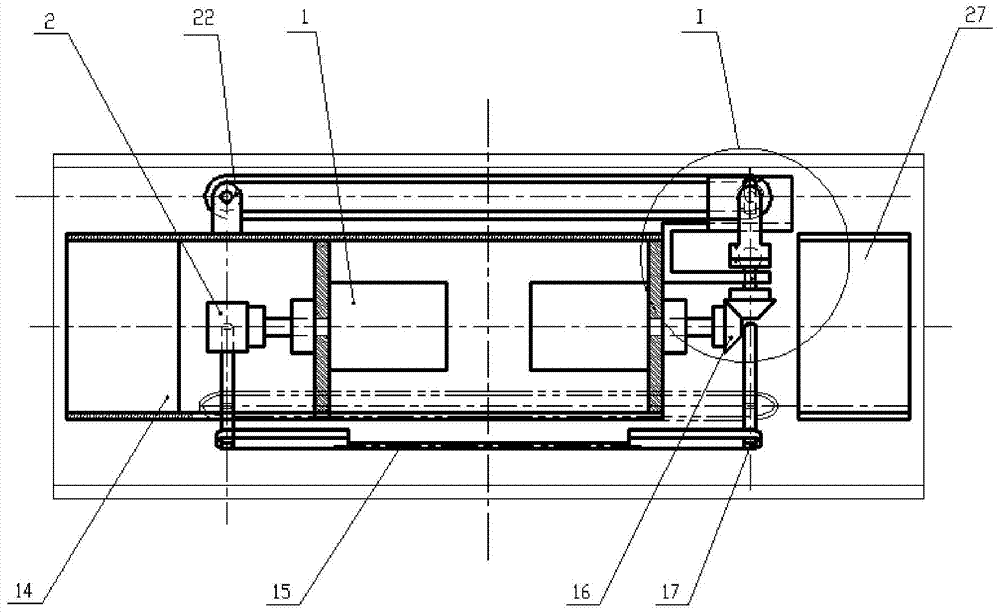

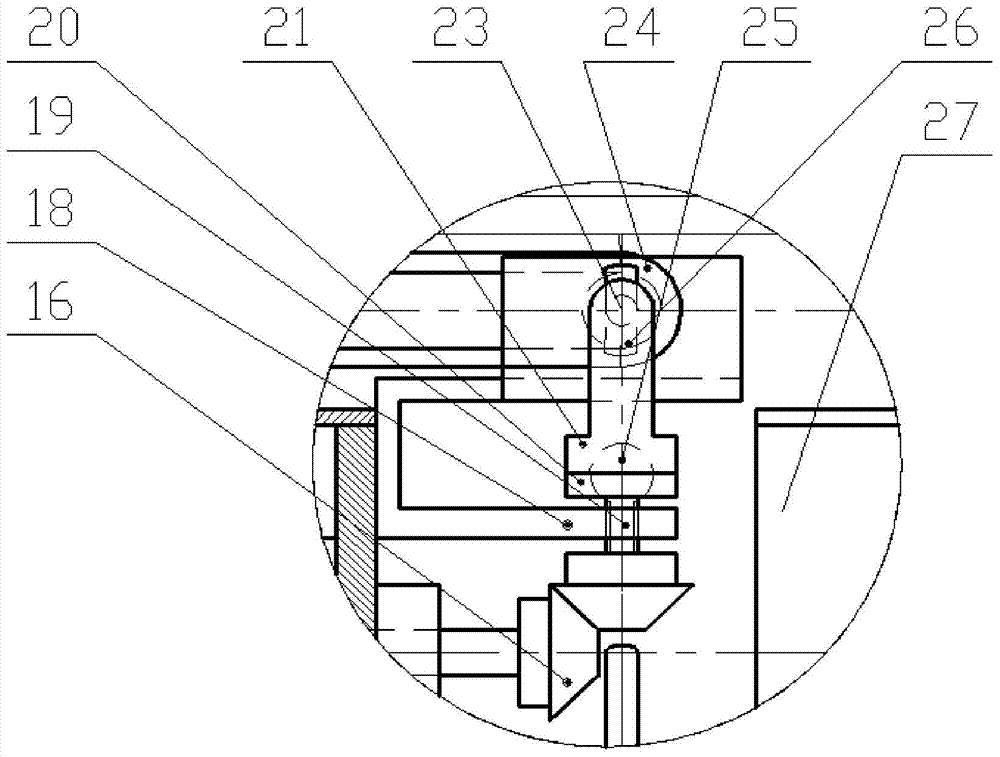

[0014] combine Figure 1~4 The main components of the drive device of the present invention include a DC motor 1, a worm rod 2, a turbine 3, a turbine shaft 4, a drive pulley 5, a first drive wheel bracket 6, a first tensioning joint 7, a driven pulley 8, Drive wheel shaft 9, drive wheel 10, first track 11, second drive wheel support 12, second tension connector 13, detector 14, track tension adjustment lever 15, bevel gear 16, driven wheel shaft 17, screw connection Seat 18, spiral ball head section 19, ball head gland 20, ball head swivel seat 21, support frame 22, support wheel shaft 23, support track 24, spiral ball head section 25, slideway 26, electric control Case 27, shaft end cover 28, support wheel 29.

[0015] Before the driving device is powered on, it is necessary to adjust the axial tightness of the track. The track tensioning adjusting rod 15 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com