Ultrasonic phased array automatic scanning device used for large-size curved-surface component

An ultrasonic phased array and scanning device technology, which is applied to measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as difficulty in using variable curvature surfaces, difficulty in defect evaluation, and low imaging accuracy. Achieve high detection efficiency, realize boundary judgment and automatic steering, and increase the effect of scanning area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

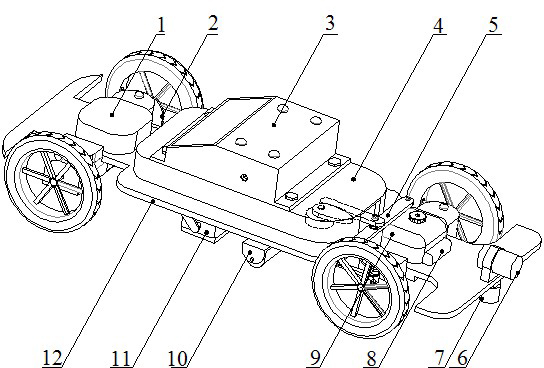

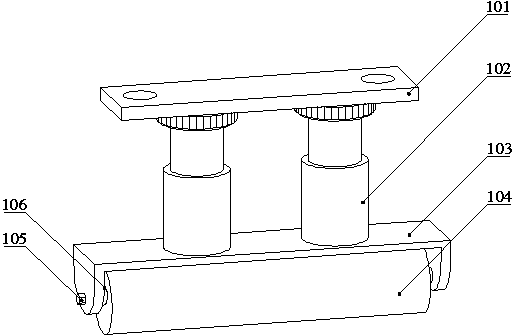

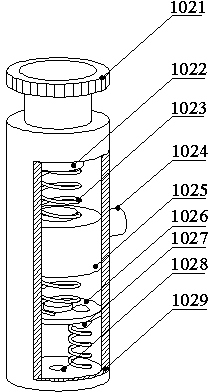

[0025] Such as figure 1 As shown, an ultrasonic phased array automatic scanning device for large curved surface components, including a power supply 1, a drive assembly 2, a processor assembly 3, a casing 4, a steering assembly 5, a pressure sensor 6, a distance sensor 7, Low-pressure pump 8, couplant storage tank 9, roller brush assembly 10, transducer assembly 11, chassis 12; the swing arm in the drive assembly 2 and steering assembly 5 is installed in cooperation with the support rod in the side wing support seat of the chassis 12; The shell 4 is installed on the chassis 12; the roller brush assembly 10 and the transducer assembly 11 are fixed in the groove of the casing by countersunk screws; the pressure sensor 6 and the distance sensor 7 are installed in the sensor seat of the chassis 12, The power supply 1 , low-pressure pump 8 and couplant storage tank 9 are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com