Optical cable for rail transit

A technology for rail transit and optical cables, applied in the field of optical cables for rail transit, can solve the problems of affecting communication performance, increasing the weight of metal reinforcements, and being easily affected by lightning, so as to reduce self weight, facilitate laying and installation, and strengthen water blocking effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

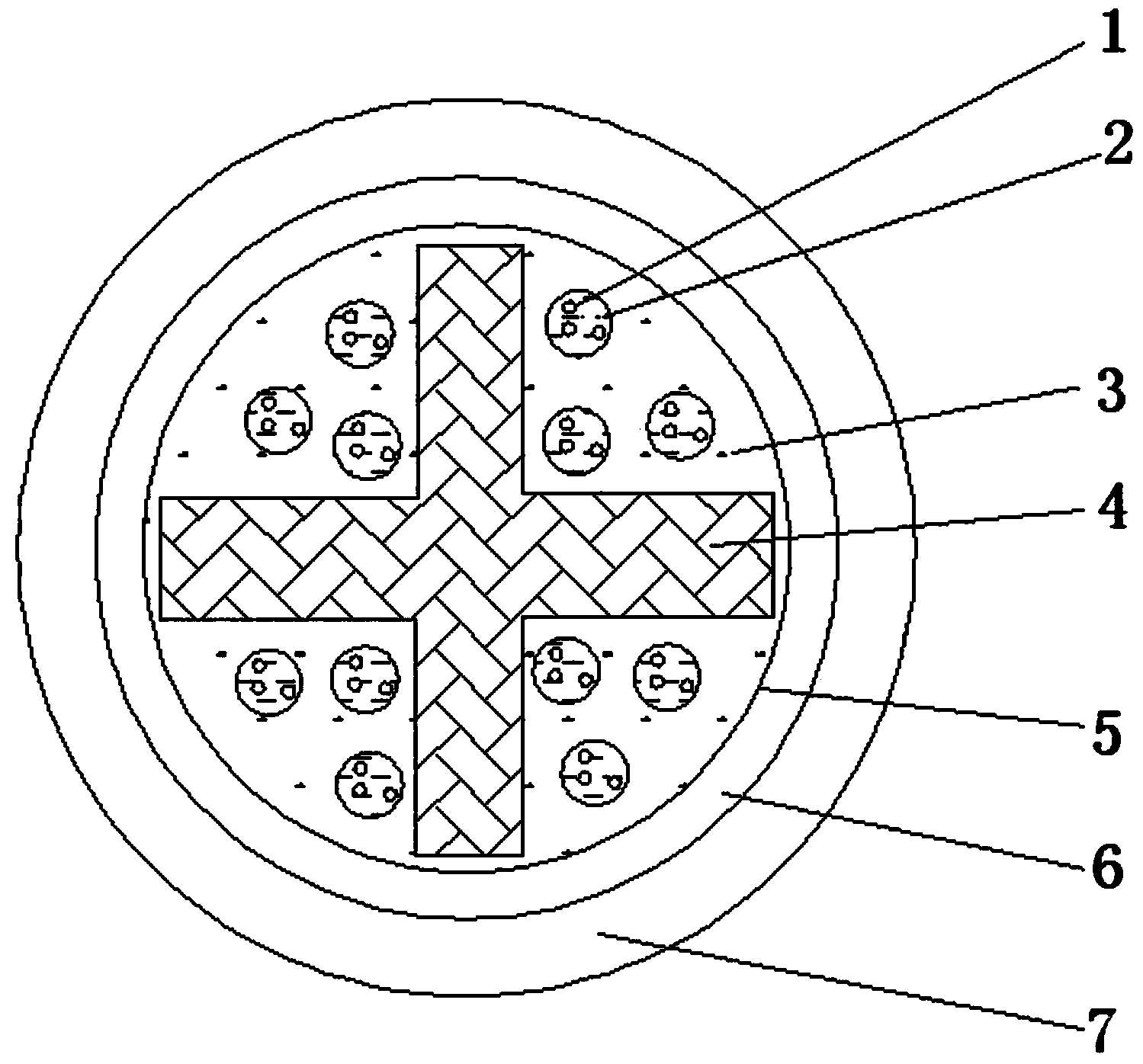

[0011] figure 1 It is a schematic cross-sectional structure diagram of an optical cable for rail transit. The optical cable for rail transit includes an optical fiber 1, a loose tube 2, a water-blocking wire 3, a skeleton 4, a yarn binding 5, an aluminum-plastic composite tape layer 6 and an outer sheath 7. The optical fiber 1 is placed directly in the loose tube 2, and the fiber paste is filled between the loose tube 2 and the optical fiber 1 to form an optical fiber core. The cross-section of the skeleton 4 of the composite carbon fiber is a cross-shaped structure, and the cross-shaped structure of the skeleton 4 divides the surroundings of the skeleton into 4 spaces, and 3 optical fiber cores are arranged in each space around the skeleton 4 . Fill the space between the optical fiber cores and between the optical fiber core and the skeleton 4 with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com