LCD panel pick and place device

A pick-and-place device and liquid crystal panel technology, applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve problems such as abnormal product quality, low operating efficiency, and inconvenient pick-and-place, and achieve reduced impact and safe pick-and-place Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

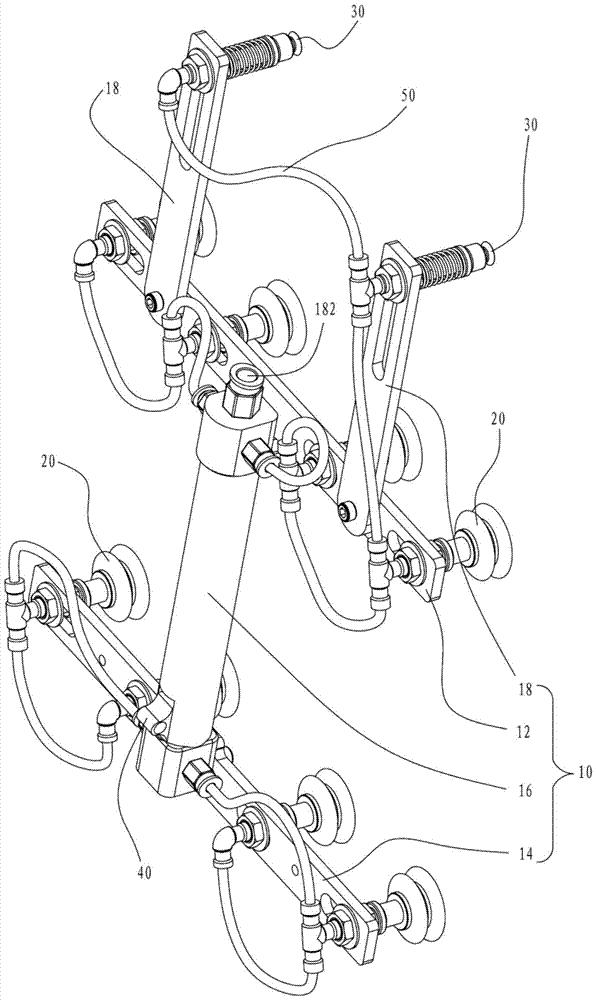

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0024] figure 1 Shown is a schematic diagram of a medium-sized liquid crystal panel, and the size range of such a liquid crystal panel is usually between 26"-32". figure 2 Shown is a schematic diagram of a large-size LCD panel, usually the size range of this LCD panel is between 48"-55". Such as figure 1 and figure 2 As shown, the liquid crystal panel includes a display screen 100 and a circuit board 200 connected to the edge of the display screen. The invention relates to a pick-and-place device for a liquid crystal panel, which is used for picking and placing the liquid crystal panel, realizes the safety of picking and placing the liquid crystal panel, and ensures that the liquid crystal panel does not separate from the pick-and-place device for the liquid crystal panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com