Free obstacle-crossing storage cargo handling tool and storage cargo handling method

A technology for handling tools and warehousing, applied in the field of remote control automatic handling tools, can solve the problems of low work efficiency, excessive physical exertion, scattered goods, etc., and achieve the effect of convenient installation and good leveling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

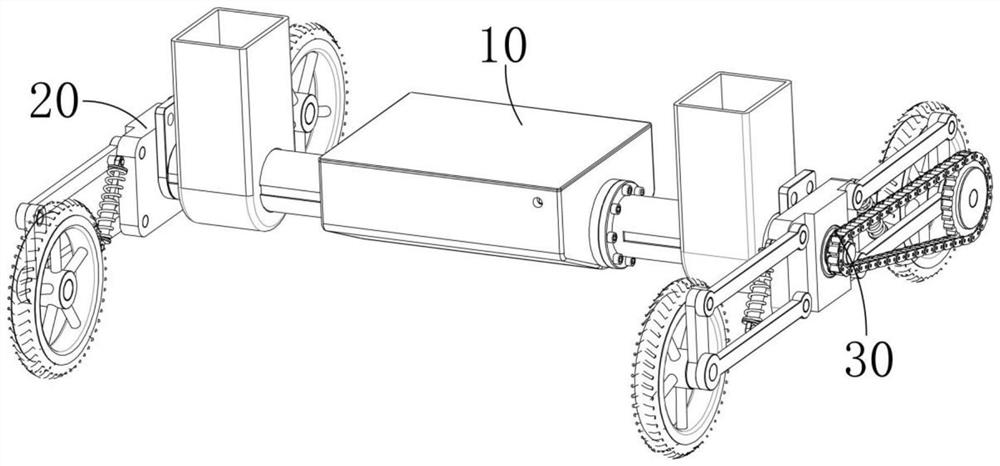

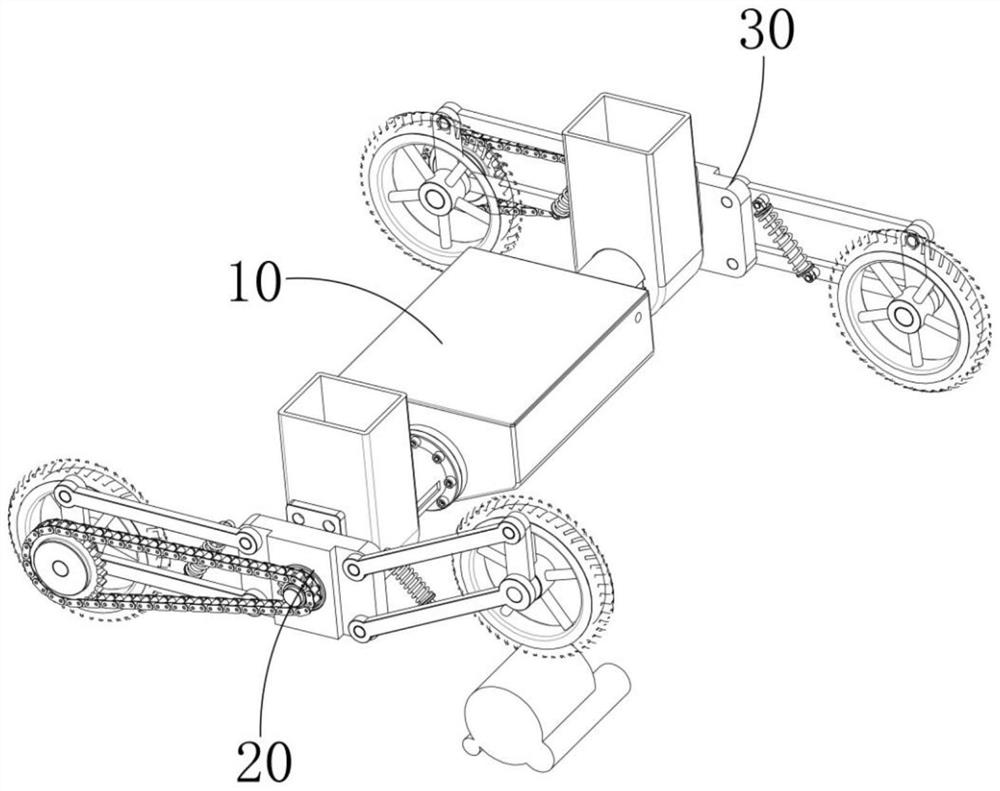

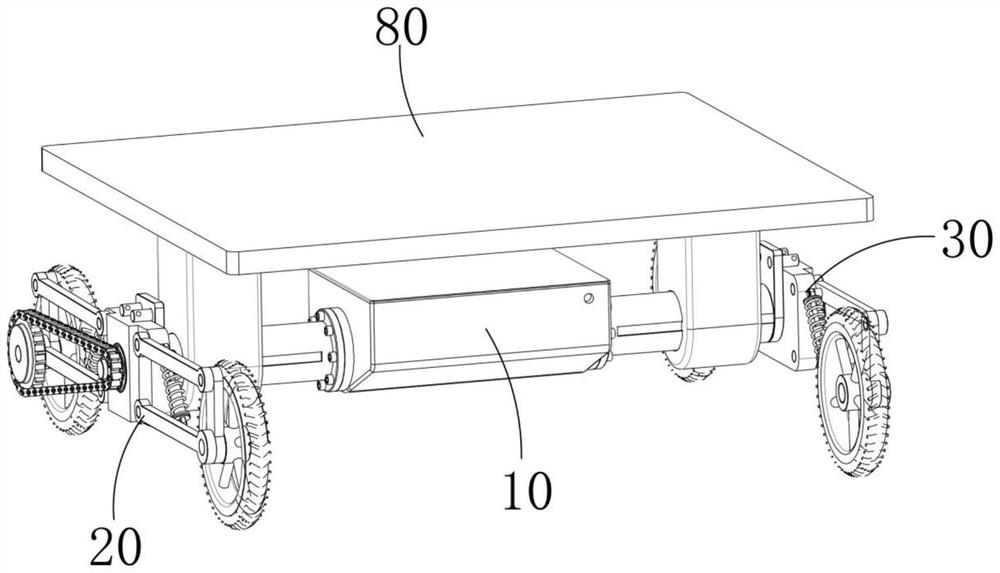

[0046] Such as Figure 1-16 As shown, the free obstacle-crossing storage cargo handling tool includes a pallet 80, a mobile control system for supporting the pallet 80 and moving the pallet 80, and the mobile control system includes a first mobile control mechanism 20, a second mobile control mechanism Mechanism 30, the installation control mechanism 10 for controlling the first movement control mechanism 20 and the second movement control mechanism 30, the installation control mechanism 10 is arranged between the first movement control mechanism 20 and the second movement control mechanism 30 between.

[0047] Such as Figure 5 As shown, the installation control mechanism 10 includes an installation shell 110, and the installation shell 110 is provided with an installation groove 120 and a controller 140. There are two installation grooves 120, and the installation groove 120 is used for To limit the installation of the first mobile control mechanism 20 and the second mobil...

Embodiment 2

[0074] Such as Figure 4 , Figure 16 As shown, a moving auxiliary bracket for a ladder is the same as the above-mentioned mobile electric transfer tray in that they both include a movement control system. The difference is that the moving control system of the auxiliary moving bracket for a ladder The upper part is set as a ladder 90, and the required mobile control systems are two.

[0075] The miter ladder 90 is used in various construction operations. During the construction process, the workers often need to carry the miter ladder 90 many times. Therefore, the workers need to go up and down the miter ladder 90 frequently, which not only affects the construction progress, but also reduces the Work efficiency, meanwhile, is unfavorable for worker's safety, also has when needing to adjust the height of the ladder 90 during construction, needs to adjust the angle between the two ladder frames of the ladder 90, makes construction more troublesome, will ladder 90 Fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com