Connecting method of hydro generator rotor support

A technology for hydroelectric generators and rotor brackets, which is applied in the manufacture of stator/rotor bodies, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., and can solve problems such as complex processing technology, difficult welding, and increased cost , to achieve the effect of simple process, short manufacturing cycle and less material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment, further illustrate the present invention.

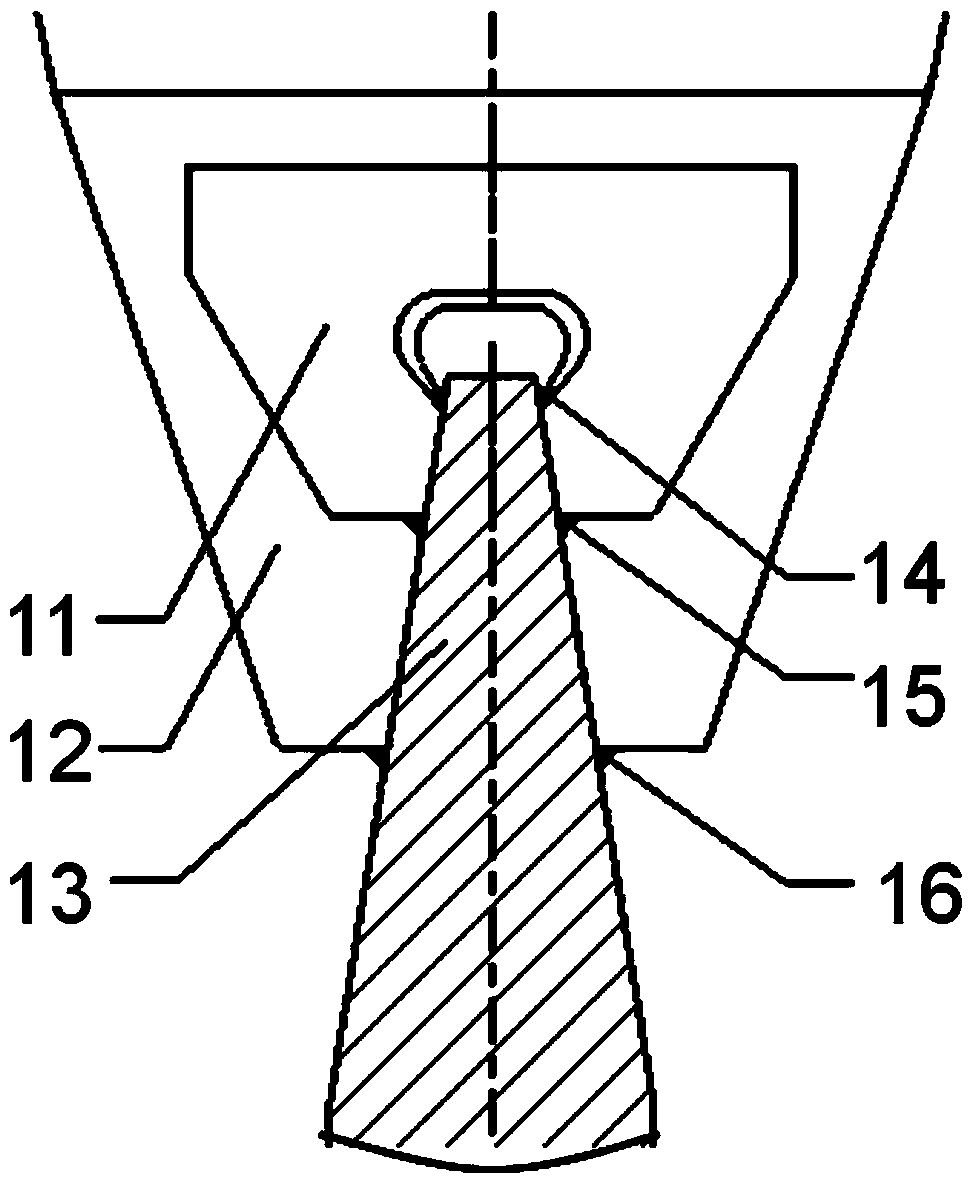

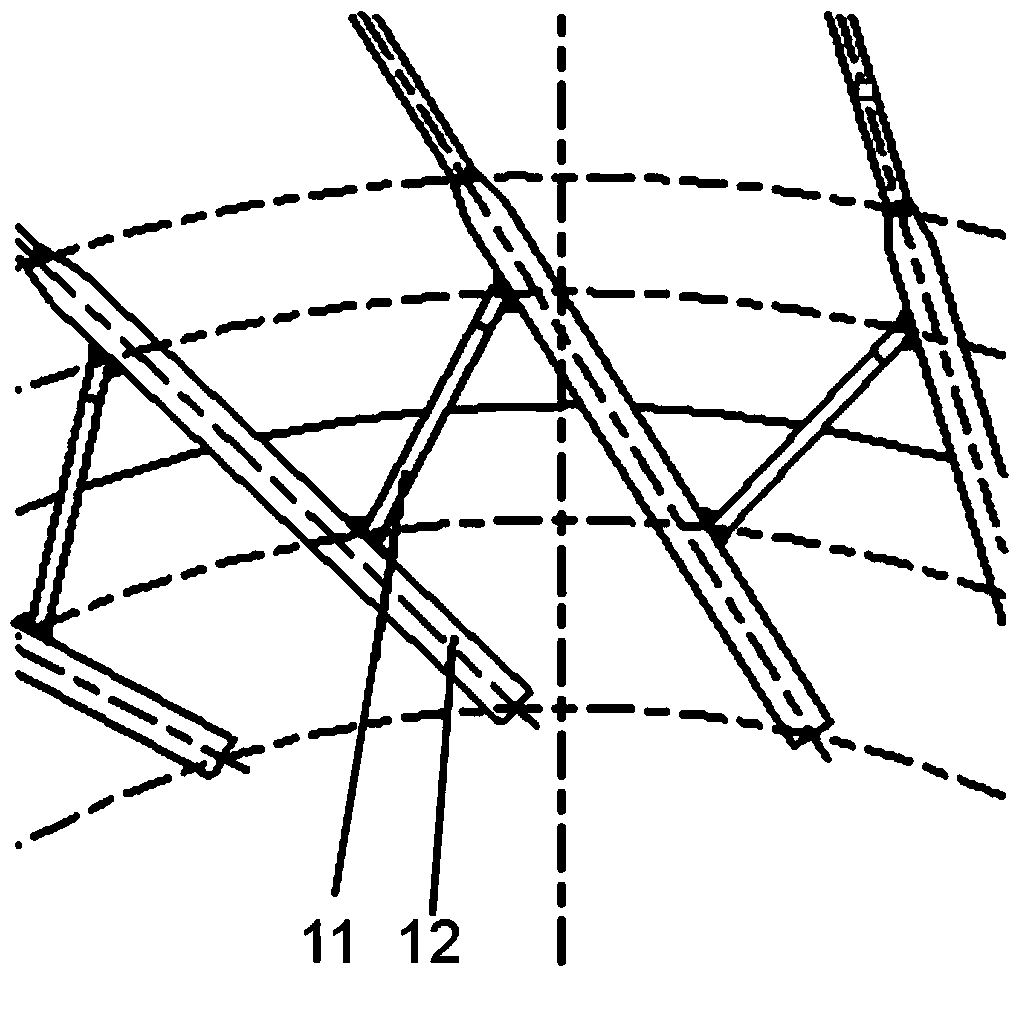

[0017] Such as figure 1 As shown, the current traditional rotor support structure includes the traditional small rib plate 11, the traditional large rib plate 12, and the traditional center ring plate 13. figure 1 Five traditional welding points 14, 15, 16, 17, 18 are welded, which causes many raw materials to be used, complicated processing technology, difficult welding and difficult quality assurance, and increased cost.

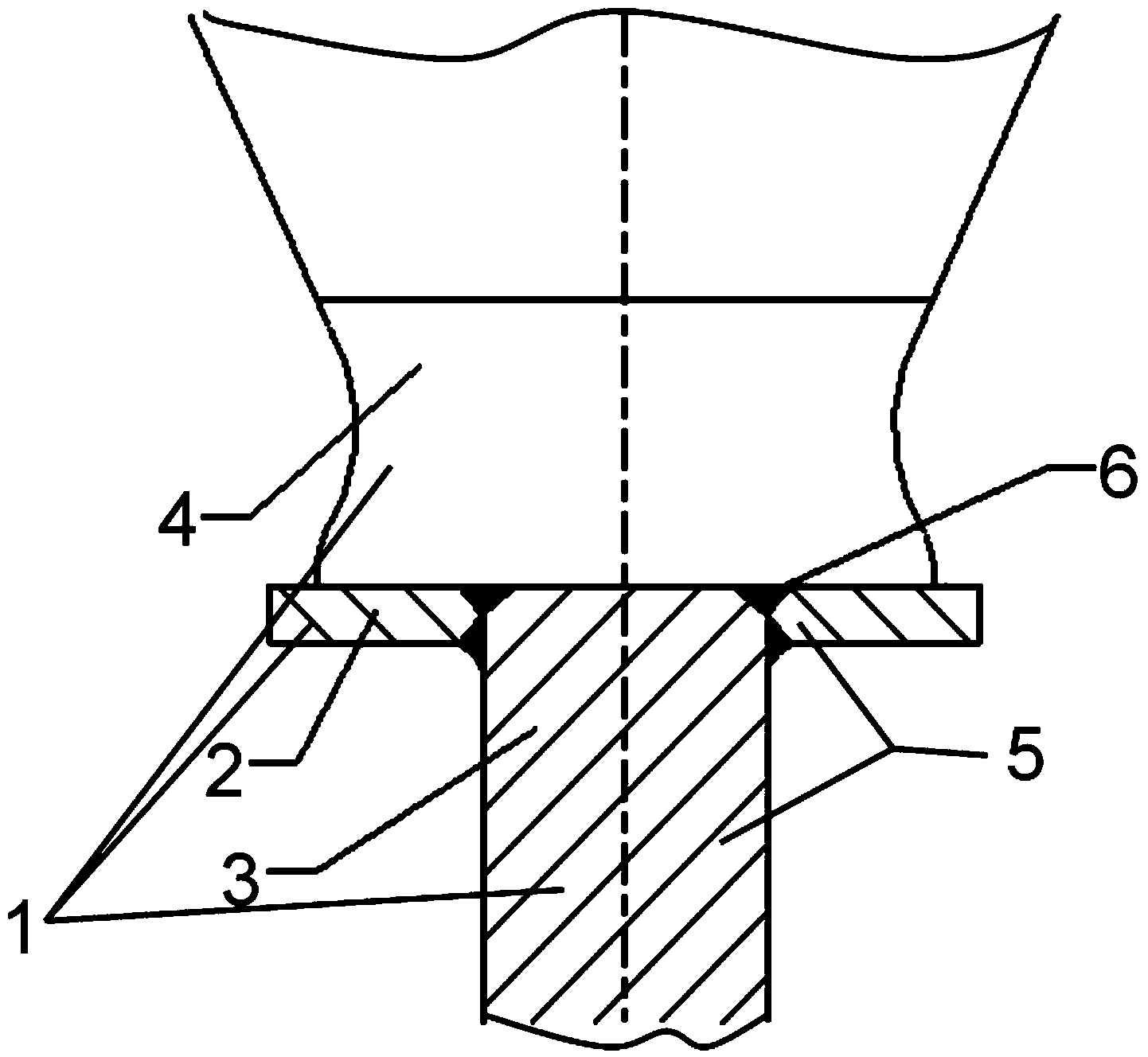

[0018] Such as figure 2 As shown, the rotor bracket 1 welded by the new method includes the ring plate 2, the center ring plate 3, and the large rib plate 4. The ring plate 2 is rolled from a steel plate and welded with the center ring plate 3. One body to form the center body blank 5, and weld the center body blank 5 with the large rib plate 4 after processing. This method only needs to weld the welding points 6 and 7, and the number of wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com