Double-faced thick copper plate, manufacturing method thereof and clamp

A production method and thick copper plate technology are applied in the secondary treatment of printed circuits, printed circuit components, and non-metallic protective layer coating, etc., which can solve the problems of double-sided thick copper circuit boards, rework of circuit boards, double-sided thick copper plates, etc. Copper plate drop and other problems, achieve the effect of saving copper, good stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

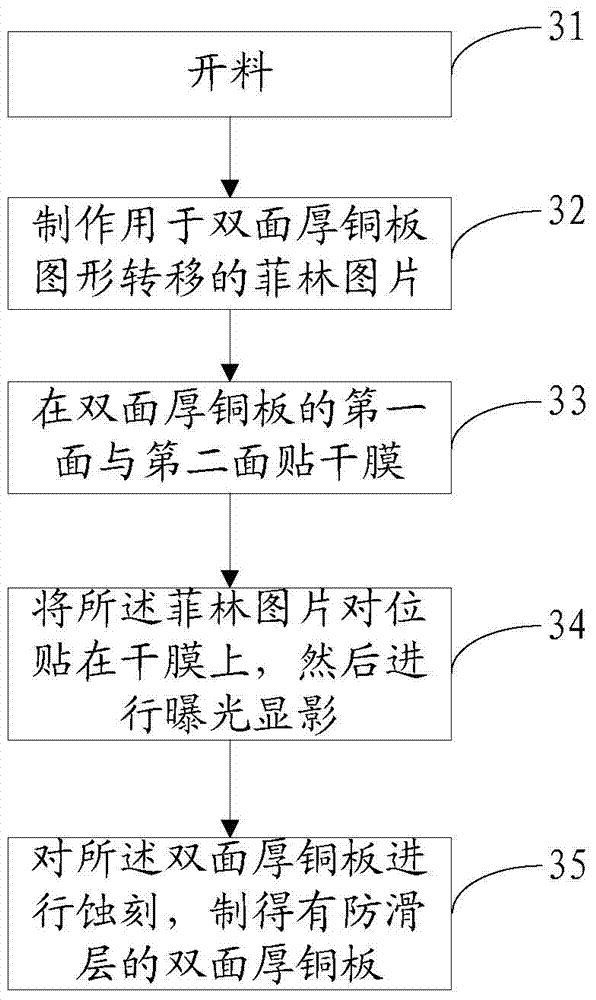

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

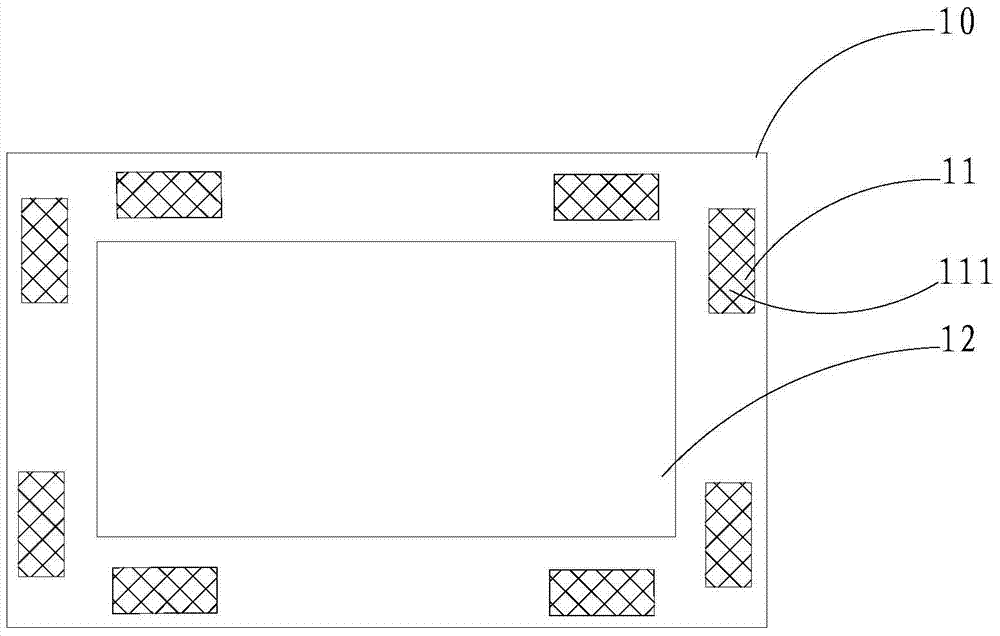

[0025] like figure 1 As shown, a double-sided thick copper plate, the first surface and the second surface of the double-sided thick copper plate 10 are provided with anti-skid areas 11, and the anti-skid areas 11 are all located on the sides of the first surface and the second surface, The anti-slip area 11 on the first surface corresponds to the anti-slip area 11 on the second surface, and the anti-slip area 11 is provided with several recesses 111 .

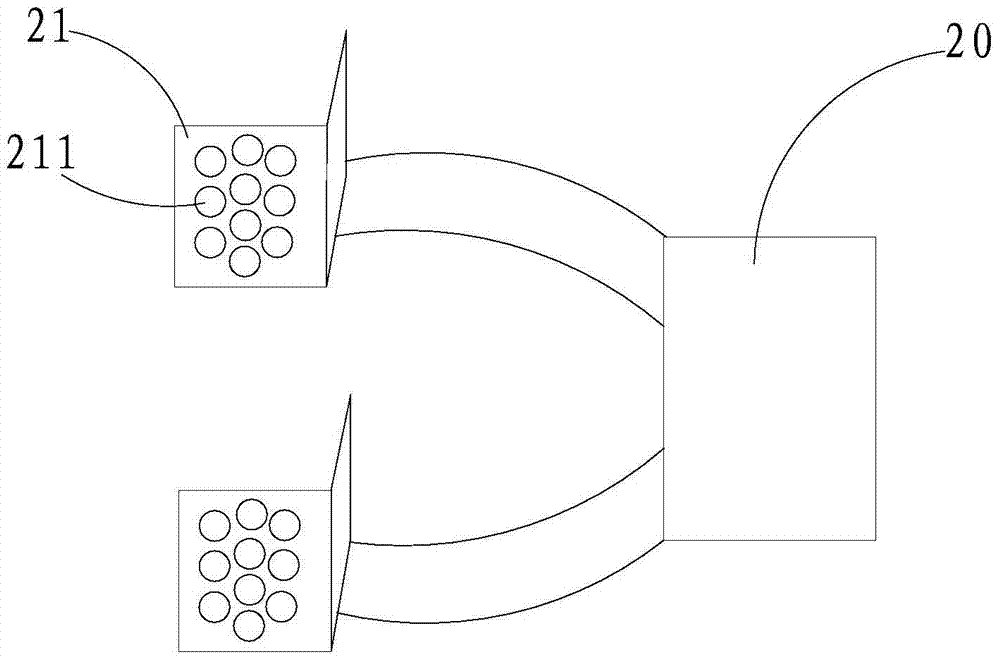

[0026] In the present invention, an anti-slip area 11 is provided on the double-sided thick copper plate 10, and the improved clamp 20 is used to clamp the anti-slip area 11 of the double-sided thick copper plate 10, wherein the anti-slip area 11 has a concave portion 111, and the clamp 20 has a convex point 211, The protrusions 211 are embedded in the recesses 111, which can greatly increase the clamping for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com