Process for producing arc-welded structural member

An arc welding and structural component technology, applied in arc welding equipment, welding media, manufacturing tools, etc., can solve the problems of reduced strength, fatigue characteristics, corrosion resistance, etc., achieve a large degree of freedom, excellent resistance to molten metal embrittlement cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

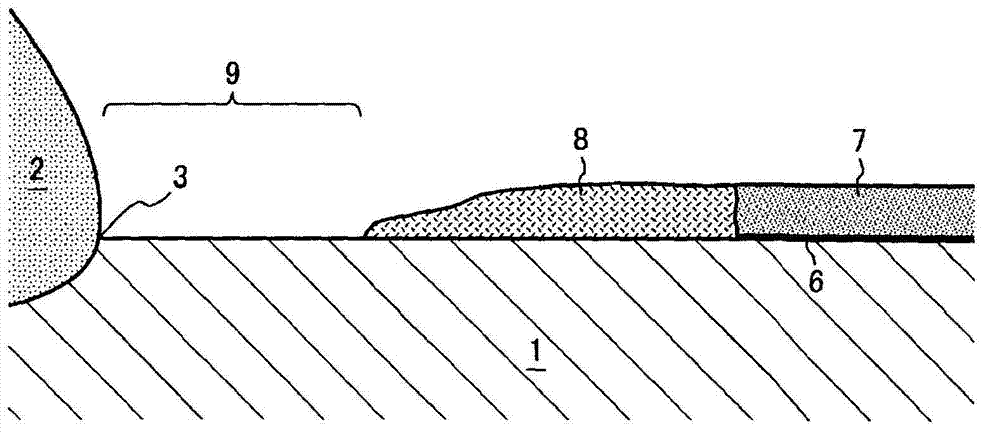

[0067] The molten Zn-Al-Mg-based plated steel sheet shown in Table 1 was placed horizontally, and a weld bead (build-up welding) was formed on the surface of the steel sheet by an arc generated from a horizontally moving torch. The welding conditions are described in Table 1. For the section perpendicular to the direction of the weld bead including the weld seam and its nearby base metal, after mirror grinding and corrosion with nitric acid ethanol corrosion solution with a concentration of 0.2 volume % nitric acid, a scanning electron microscope is used to observe the weld bead seam. Near the edge, measure Figure 5 The length of the coating evaporation area shown by the symbol L in the middle.

[0068] [Table 1]

[0069]

[0070] Image 6 Indicates its result. Image 6 The case where the length of the plating evaporation region is 0.3 mm or more is drawn with the ○ mark, and the case of less than 0.3 mm is drawn with the X mark. With welding input heat Q(J / cm) and CO...

experiment example 2

[0072] The molten Zn-Al-Mg system plated steel sheet shown in Table 1-2 (the plate thickness of the plated plate is 2.6 mm) is placed horizontally, and a weld bead is formed on the surface of the steel plate by an arc generated from a horizontally moving welding torch (surfacing welding ( Bird On Plate)). Welding conditions are recorded in Table 1-2. By observing the vicinity of the edge of the weld bead with the same method as in the above-mentioned experimental example 1, it is determined that Figure 5 The length of the coating evaporation area shown by the symbol L in the middle.

[0073] [Table 1-2]

[0074]

[0075] Figure 8 Indicates its result. Figure 8 The case where the length of the plating evaporation region is 0.3 mm or more is drawn with the ○ mark, and the case of less than 0.3 mm is drawn with the X mark. With welding input heat Q(J / cm) and CO in shielding gas 2 Concentration C CO2 (volume%) is related to C CO2 =205Q -0.32 The curve of is the boun...

Embodiment 1

[0090]A cold-rolled steel strip with a thickness of 3.2 mm and a width of 1000 mm having the composition shown in Table 2 was used as a coating original plate, and passed through a molten coating line to produce molten Zn-Al-Mg systems with various coating compositions. Plated steel. Each molten Zn-Al-Mg-based plated steel sheet was subjected to gas-shielded arc welding according to the test method shown below, and the influence of the shielding gas composition on the resistance to molten metal embrittlement cracking was investigated. The composition of the plating layer, the amount of plating deposition, and the composition of the shielding gas are shown in Table 4 below. The composition of the protective gas applied to the example of the present invention contains CO 2 : 0 to 16% by volume, remainder: one or more of Ar and He (the same applies to Examples 2 and 3 described later).

[0091] [Table 2]

[0092]

[0093] (Test method for resistance to molten metal embrittl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com