Sealing device for exhaust gas of electrophoresis production

A waste gas treatment device and electrophoresis technology, which are applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of working environment pollution, environmental pollution, incomplete waste gas collection, etc., to reduce direct pollution and improve the working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

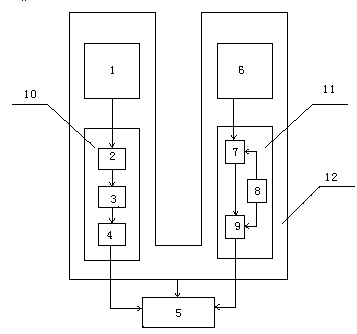

[0011] See attached figure 1 , the present invention includes a drying device 1, a drying exhaust gas treatment device 10, an electrophoresis pretreatment device 6, an electrophoresis acid gas treatment device 11, a purification gas discharge pipe 5, and a sealed chamber 12. The drying device 1, drying The dry waste gas treatment device 10, the electrophoresis pretreatment device 6, and the electrophoresis acid gas treatment device 11 are arranged in the sealed chamber 12, and the sealed chamber 12, the dry waste gas treatment device 10 and the electrophoresis acid gas treatment device 11 are respectively discharged from the purified gas. Tube 5 is connected.

[0012] The drying exhaust gas treatment device 10 described above includes a water curtain cooling tank 2, a water vapor countercurrent cleaning tank 3, and an activated carbon adsorption tower 4 connected in sequence; 8. A secondary acid mist absorption tower 9, the lye pool 8 is connected to the primary acid mist abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com