Automatic feeding crusher

A technology of automatic feeding and crusher, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of time-consuming and laborious, incomplete crushing, health threat to operators, etc., to improve work efficiency, save manpower, prevent clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

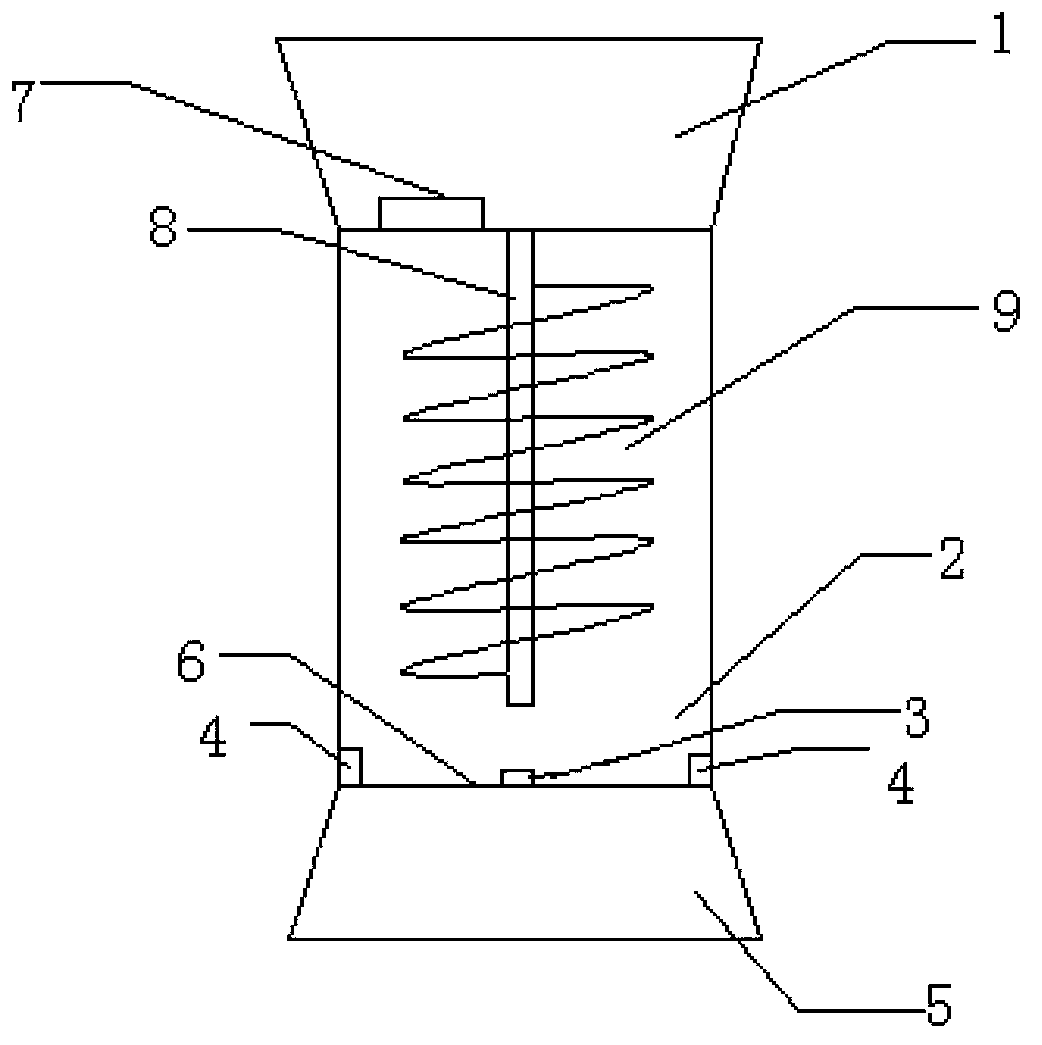

[0012] Such as figure 1 , shown in the schematic diagram of the present invention, the present invention is made up of feeding chamber 1, crushing chamber 2 and receiving chamber 5, and feeding chamber 1 is fixedly connected with crushing chamber 2, and crushing chamber 2 is fixedly connected with receiving chamber 5, and feeding The bottom of the chamber 1 is provided with a feed port 8, the bottom of the crushing chamber 2 is provided with a screen 6, and the center of the top of the crushing chamber 2 is provided with a rotating shaft 8, and a blade 9 is provided on the rotating shaft 8, and the blade 9 is in a spiral shape. Extending from the top of the rotating shaft 8 to the bottom of the rotating shaft 8, the edge of the screen cloth 6 is provided with an oscillator 4, and the central position of the screen cloth 6 is provided with a gravity sensor 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com