A die-casting mold for button die-casting parts and the application of air-permeable steel on the die-casting mold

A die-casting mold and breathable steel technology, applied in the field of mold manufacturing, can solve the problems of unstable polishing quality, low production efficiency, harsh polishing requirements, etc., to avoid surface quality problems, improve surface quality, and reduce production cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

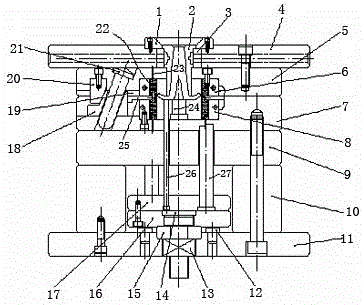

[0033] In the following, with reference to the drawings and preferred embodiments, the specific implementation, structure, features and effects of a button die-casting die-casting mold and the application of air-permeable steel on the die-casting die according to the present invention will be described in detail as follows.

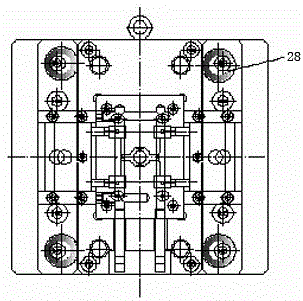

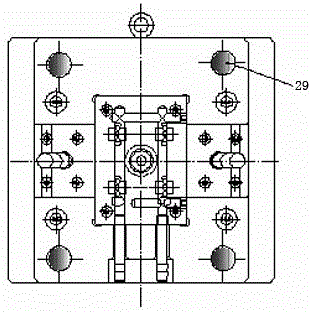

[0034] see Figure 1-3, a button die-casting die-casting mold, including a movable mold, a fixed mold, the movable mold includes a lower template 11, a horn 10, a movable mold backing plate 9, a movable template 7, a guide sleeve 28 and a movable mold cavity 8; the fixed mold includes an upper mold cavity Formwork 4, fixed formwork 5, guide post 29 and fixed mold cavity 6; upper formwork 4 has positioning ring 1, sprue sleeve 2, gate bushing 3; Rod plate 16 and upper ejector plate 17, lower ejector plate 16 and upper ejector plate 17 have ejection cushion block 14, ejector rod 26 and reset rod 27, there is pad between lower ejector plate 16 and lower form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com