Material bin and bin leveling and unloading device thereof

A material silo and warehouse technology, which is applied in the field of material silos and their leveling and discharging devices, can solve the problems of height difference, uneven stacking of materials, and inability of materials in the material silos to be completely discharged from the warehouse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

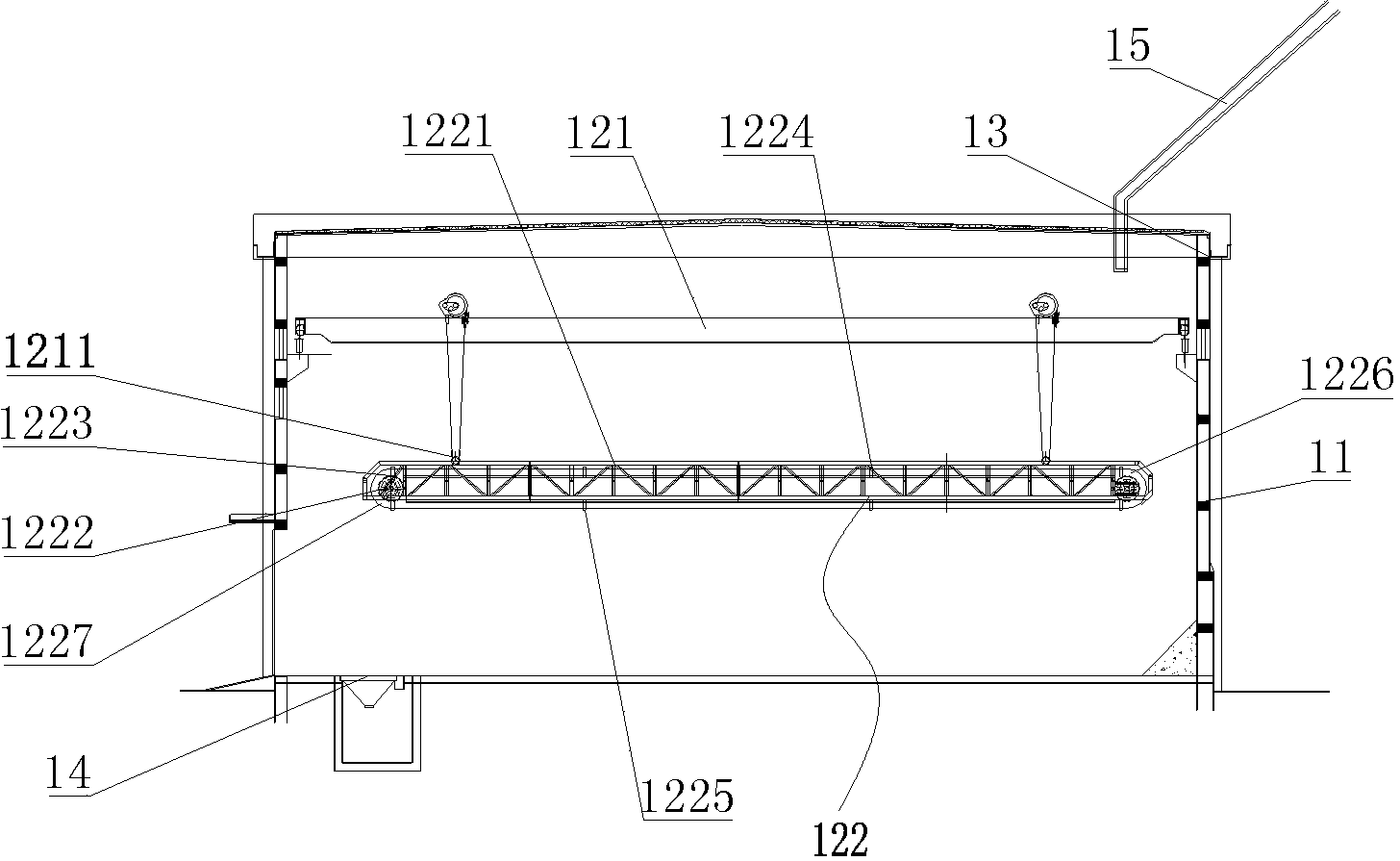

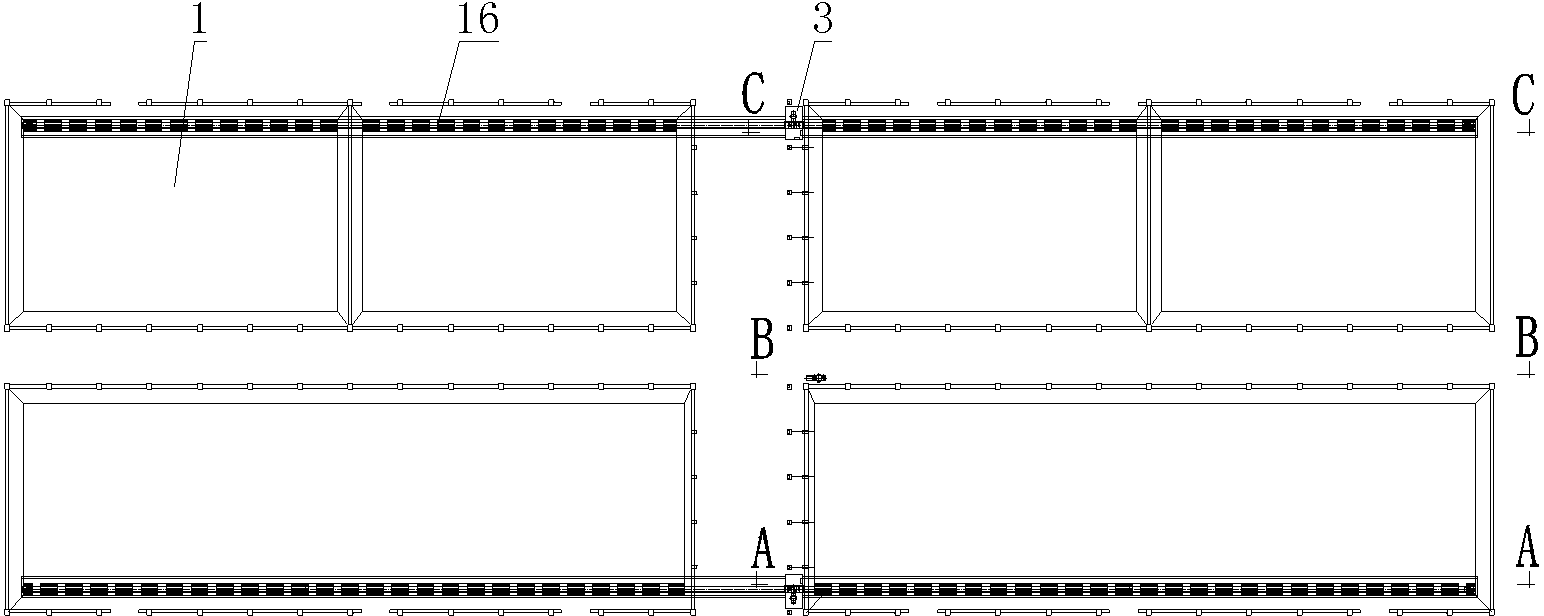

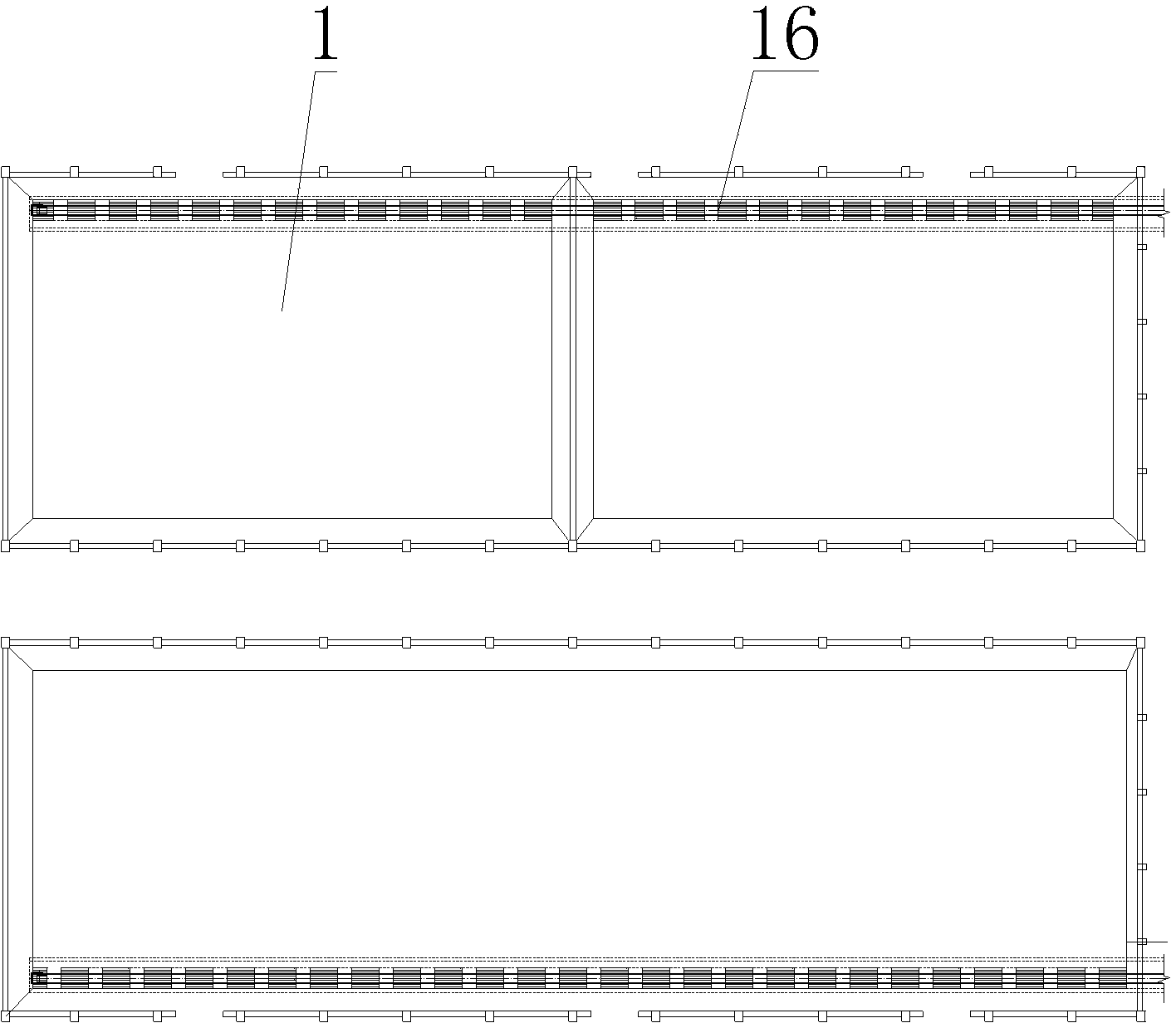

[0032] The embodiment of material bin among the present invention: as Figure 1 to Figure 14 As shown, the material warehouse is a granary composed of four warehouse units 1, wherein each warehouse unit 1 is composed of a warehouse 11, a feeding conveying device, a material discharging conveying device and a flat outlet device, adjacent to the left and right A pair of warehouse units 1 form a warehouse group, and the two warehouse groups are divided into a front warehouse group and a rear warehouse group according to the front and rear positions, and the front warehouse group and the rear warehouse group share a working tower 2.

[0033] The flat-out warehouse device is composed of bridge crane 121 and flat-out warehouse scraper conveyor, wherein the bridge crane 121 bridges the top of the left and right vertical walls of the warehouse 11 and walks along the front and rear directions, and is on the left and right sides of the bridge crane 121. There are respectively equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com