Bottom paper and top paper synchronous paper feeding device and control method

A technology of paper feeding device and surface paper, which is applied in the directions of transportation and packaging, object supply, and winding strips. The effect of frequent starting, improving efficiency, and ensuring consistency of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

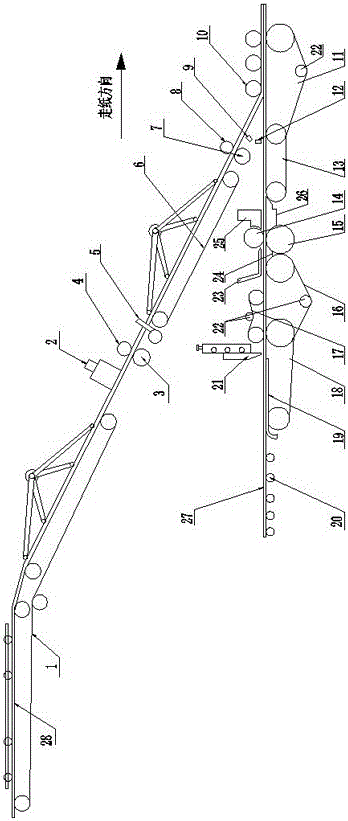

[0023] see figure 1 , an embodiment of a synchronous paper feeding device for bottom paper and face paper in the present invention, comprising a low-speed paper feed belt assembly 1 for the face paper, a side pull gauge 2 for the face paper, a high-speed paper pulley 3 for the face paper, a pressure roller 4 for the face paper, and Paper front gauge 5, surface paper high-speed paper conveyor belt assembly 6, bottom paper support roller 20, bottom paper lifting plate assembly 19, bottom paper side stop device, bottom paper front gauge 21, bottom paper feeding suction belt Component 18, bottom paper suction air distribution valve, glue roller 14, water applicator roller 15, pressing suction belt assembly 11, pressing roller 10, surface paper motor and bottom paper motor. The front stop gauge 5 of the face paper, the pressure paper wheel 4 of the face paper, the side pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com