Biodegradable hydraulic oil composition

A technology of oil composition and degradation liquid, applied in lubricating composition, petroleum industry, additives, etc., can solve the problem of not mentioning the performance of biodegradation characteristics of products, and achieve outstanding biodegradable characteristics, good viscosity-temperature performance, excellent Effects of Oxidative Stability

Active Publication Date: 2015-02-11

CHINA PETROLEUM & CHEM CORP

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The downside is that the work does not mention how the product behaves in terms of biodegradation properties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

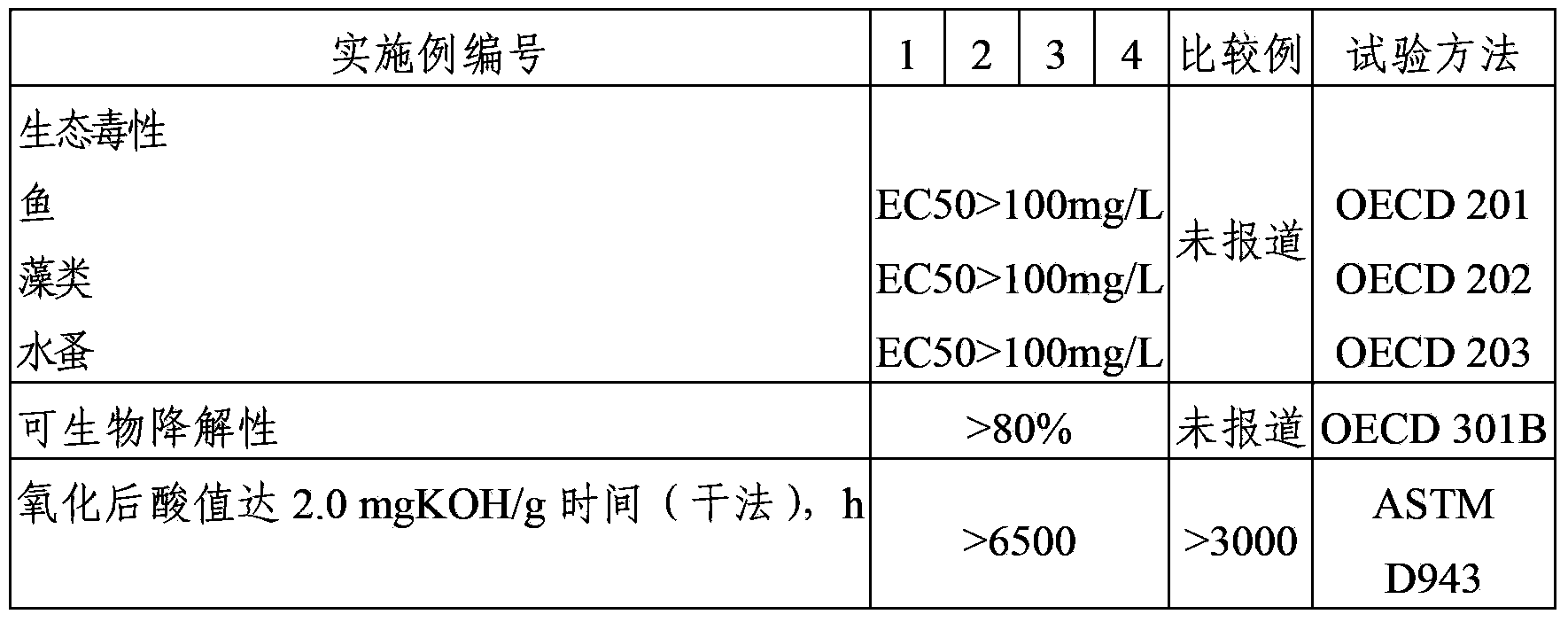

[0033] Prepare the biodegradable hydraulic oil composition of the present invention according to the formula in Table 1.

[0034] The formula of table 1 embodiment 1~4

[0035] components

[0036] Dialkylimidazoline

[0037] Mix the above formula according to the proportion of each component, and stir at 60°C for 3 hours to obtain the product.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Login to View More

Abstract

A provided biodegradable hydraulic oil composition is composed of the following compositions in percent by weight: 0.1-5% of a phenol type or amine anti-oxidant type anti-oxidant , 0.1-5% of a P type or S-P type nonmetal extreme-pressure anti-wear reagent, 0.01-1% of an ashless clean dispersant, 0.01-1% of an ester or calcium sulfonate antirust agent, 0.01-1% of an organic metal passivator, and the balance ester base oil. The beneficial effects comprise that compared with common hydraulic oil, the product possesses protrude biodegradable characteristic (with biodegradation rate greater than 80%, OECD301B) and excellent oxidation stability (with the time longer than 6500 h when the acid value is 2.0 mg KOH / g, ASTMD943(dry)).

Description

technical field [0001] The invention relates to a lubricating oil composition, in particular to a hydraulic oil composition with outstanding biodegradability and excellent oxidation stability. Background technique [0002] At present, among the lubricants used all over the world, except for a part that is normally consumed by mechanical operation or partially recycled and reused, 4% to 10% of the lubricant still flows into the environment during assembly, disassembly, filling, and mechanical operation. Each year there are about 6×10 5 t lubricants are lost to the environment for various reasons. Traditional lubricant products based on mineral oil have poor biodegradability and long residence time in the natural environment. Once they penetrate into the soil and aquifer, they will cause serious damage to the environment. With the continuous enhancement of human environmental protection awareness, lubricants, especially hydraulic oil, which occupies an important proportion o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M141/10C10N40/08C10N30/10

Inventor 杜雪岭陈惠卿贾睿水琳汤涛韦安柱曹玉发王向阳薛玉苓

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com