High color and luster artificial leather with characteristic of adhesion resistance during rolling

A technology for artificial leather and color and luster, applied in the field of artificial leather, can solve the problems of inconvenient packaging or storage, poor fabric elasticity, low color and luster, and achieve the effects of improving waterproof performance, good elasticity and high color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

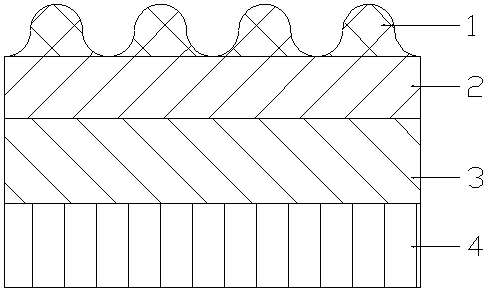

[0015] See figure 1 , The present invention is an artificial leather with high color and luster that is not easy to stick when rolled up. It includes a surface layer 3 and a base layer 4 that are bonded to each other. The surface layer 3 is bonded with a transparent film 2, and the transparent film 2 is provided with Embossing 1.

[0016] The base layer 4 is made of fabric, the fabric includes a base cloth layer, the front side of the base cloth layer is provided with a waterproof coating, the structure of the base cloth layer is a heavy weft structure, and consists of a set of warp yarns and two sets of weft yarns. It is interwoven, the warp yarn is 150D polyester viscose yarn, the weft yarn is R3.5N polyester viscose yarn + 300D bright polyester viscose network yarn, and the back of the base fabric layer is placed on one side of the surface layer and fixedly connected with the surface layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com