Double-layer film bag device and method for sealing grouting pipes in gushing sandy soil layers

A technology for grouting pipes and sand layers, which is applied in earthwork drilling, shaft equipment, sealing/isolation, etc. It can solve the problems of easy flushing, easy damage of single-layer membrane bags, loose sand layers and easy collapse of holes, etc. , to achieve the effect of easy binding, less man-hour consumption, and improved sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

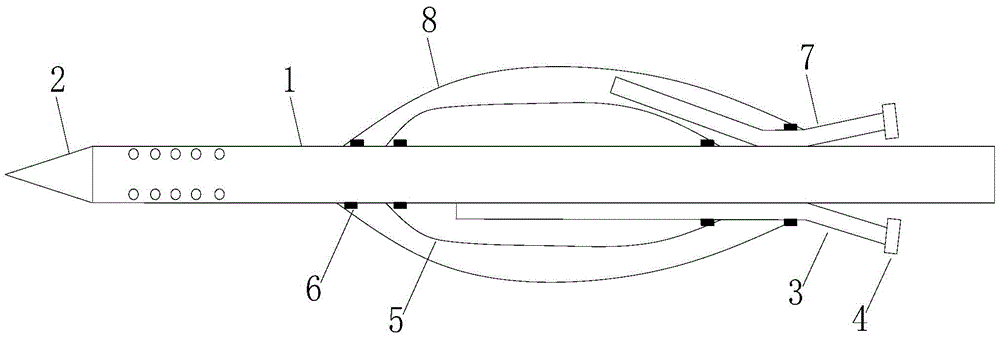

[0030] A double-layer film bag device used for sealing grouting pipes in gushing sandy soil, such as figure 1 As shown, it is mainly composed of an outer film bag 8, a rubber hose 7, an inner film bag 5, an iron pipe 3 and a grouting flower tube 1. The outer film bag 8 is fixed to the rubber hose 7 and the grouting flower tube by binding iron wire 6. On the pipe 1, the rubber hose 7 is placed inside the outer film bag 8 and outside the inner film bag 5, and the inner film bag 5 is fixed on the iron pipe 3 and the grouting flower pipe 1 by binding iron wire 6. The iron pipe 3 is placed inside the inner film bag 5 and outside the grouting flower tube 1. The front part of the grouting flower tube 1 is provided with a conical piercing end 2, and the inner film bag 5 and the grouting flower tube 1 are formed. The first grout barrier layer, the outer membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com