Built-in oil pump gear chamber

A technology for gear chambers and oil pumps, which is applied to oil pans, mechanical equipment, engine components, etc. It can solve the problems of oil pump casing expansion, increased oil leakage probability, and seal failure, so as to reduce processing difficulty and solve sealing problems. Sexual failure, the effect of ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

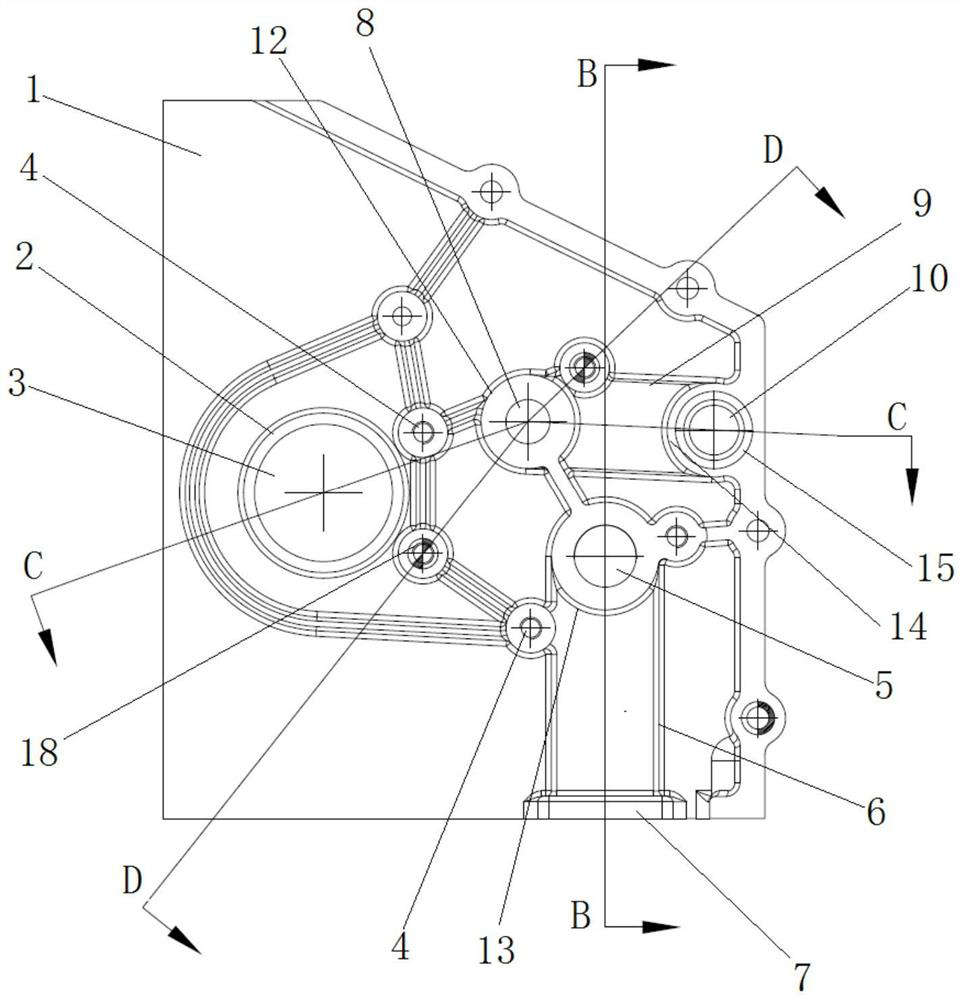

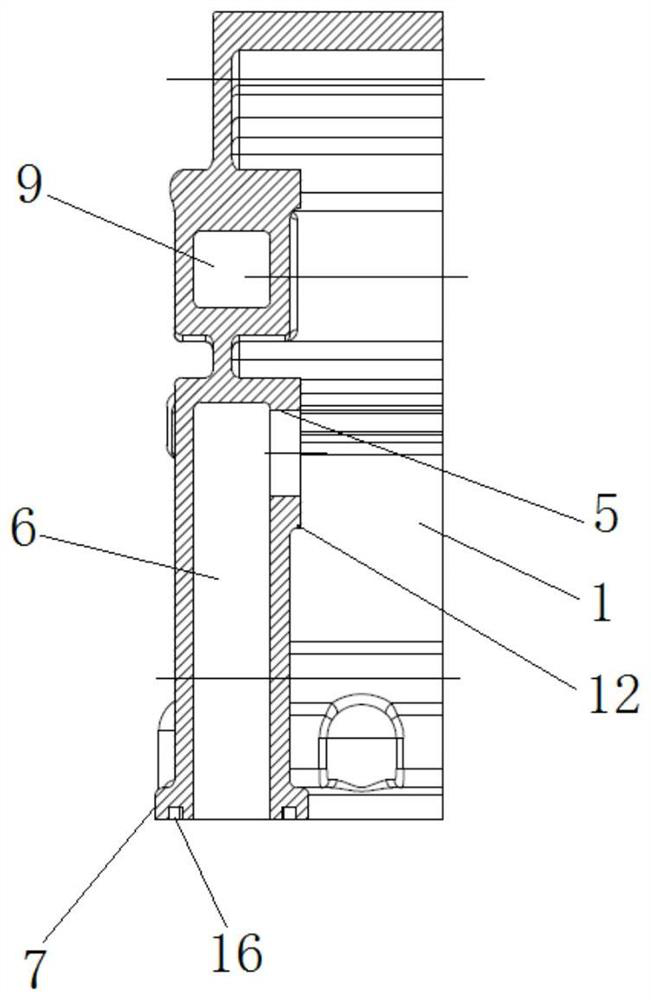

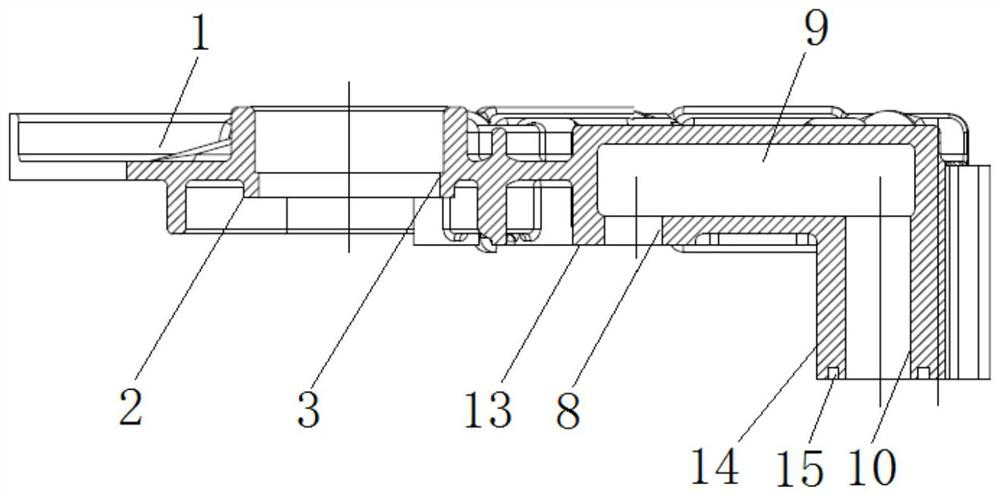

[0026] The specific embodiment of the present invention is as follows: Figure 1-8 As shown, a gear chamber with built-in oil pump includes a gear chamber 1. A positioning boss 2 is arranged in the gear chamber 1. The positioning boss 2 is provided with a crankshaft front oil seal mounting hole 3 which is adapted to the crankshaft. 1 is provided with a plurality of oil pump installation holes 4 on the bottom wall, and an oil inlet hole 5 is arranged on the inner side of the plurality of oil pump installation holes 4, and the hole wall of the oil inlet hole 5 is provided with a downward extension to the gear chamber 1. The oil inlet passage 6 at the bottom end is provided with an oil inlet flange 7 at the oil passage open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com