Micro light-emitting element array substrate, and preparation method and transfer method thereof

An array substrate and micro-light emitting technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, and electric solid-state devices, etc., can solve the problems of small distance between micro-LEDs, small size of micro-LEDs, and difficult substrate peeling process, etc. The effect of preventing incomplete peeling and facilitating peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

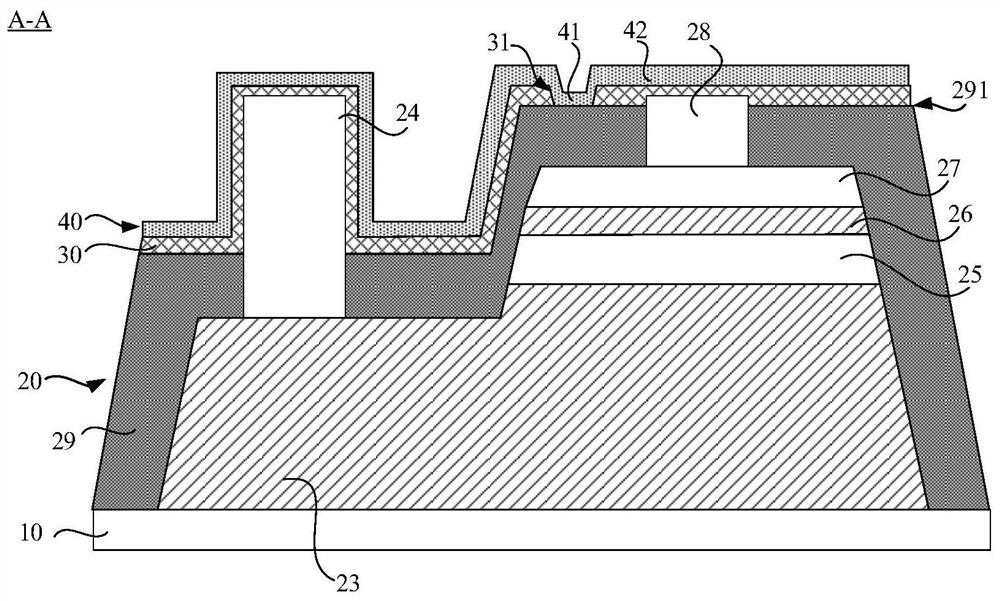

[0072] An embodiment of the present invention provides a method for preparing a micro-LED array substrate, comprising the following steps:

[0073] S110, providing a substrate;

[0074] S120, forming a micro light emitting diode chip on the substrate, the surface of the micro light emitting diode chip facing away from the substrate is a connection surface;

[0075] S130, forming a patterned sacrificial layer on the connection surface, where the sacrificial layer includes at least one first opening;

[0076] S140, forming an isolation layer on a side of the sacrificial layer away from the micro light-emitting diode chip, the isolation layer fills the first opening, and the isolation layer forms a connection structure at the first opening.

[0077] The micro-light emitting element array substrate manufactured by the above method can form a stable connection between the sacrificial layer and the micro light emitting diode chip, and the connection structure can form a stable conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com