Staggered connection process boss tool and method for machining workpiece

A technique for crafting bosses and workpieces, which is applied to metal processing machinery parts, positioning devices, grinding workpiece supports, etc., can solve the problems of restricting the production cycle of parts, low efficiency, and long manual processing time of fitters, so as to ensure the connection strength and Rigidity, high working efficiency, easy to break off and grind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described, but the patent of the present invention is not limited to this example.

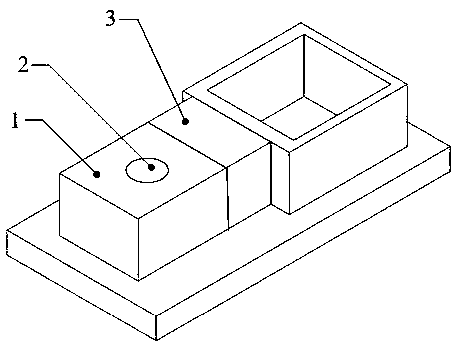

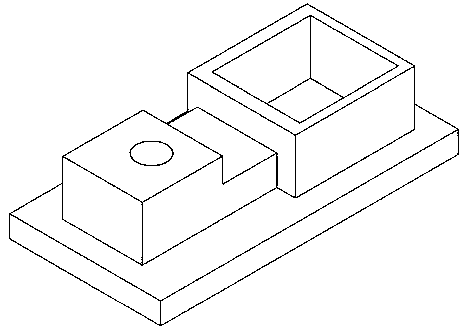

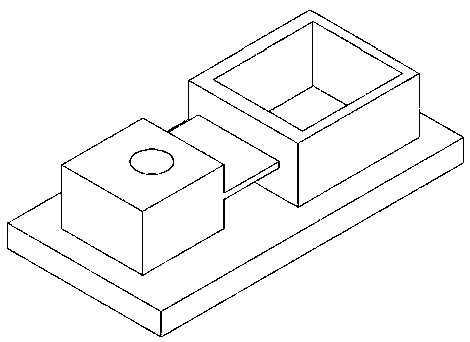

[0026] A dislocation connection process boss tooling, such as figure 1 , Figure 4 , Figure 5 and Figure 6 As shown, it includes a process boss body 1 and a workbench 5. The process boss body 1 is provided with a compression hole 2, and the bolt 6 passes through the compression hole to fix the process boss body 1 on the workbench 5. The process The boss body 1 and the workpiece 4 are connected by a connecting piece, and the connecting piece includes two high-position connecting blocks 7 and low-position connecting blocks 8 respectively. The high-position connecting block 7 and the low-position connecting block 8 are horizontally and vertically Displacement arrangement (such as Figure 6 shown).

[0027] The structure of the dislocation connection boss changes with the processing pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com