Electrolytic aluminum foil blowing switching module at outlet of stamping unit

A technology of switching components, aluminum foil, applied in the direction of gold powder printing, engine components, printing process, etc., to achieve the effect of flattening paper, reducing noise level, and reducing air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

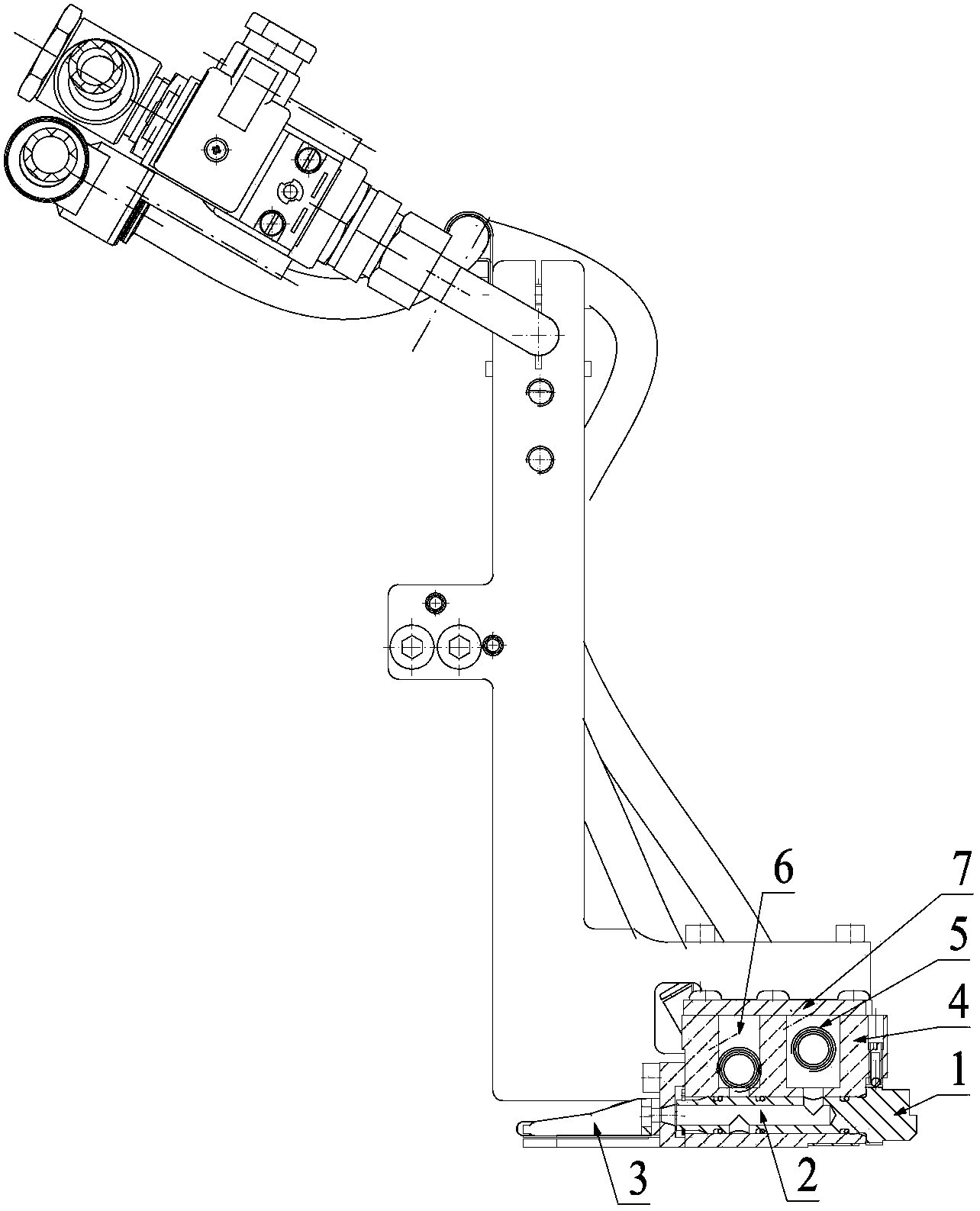

[0016] The electrolytic aluminum foil blowing switching assembly at the outlet of the hot stamping part is installed at the outlet of the hot stamping machine to control the air output of the blowing device. The structure of the switching assembly is as follows: figure 1 As shown, it is mainly composed of a switching lever 1 and an air blowing main body 4 . The end of the switching rod 1 is provided with an air outlet 3, and an air outlet pipe 2 is arranged inside. The cavity communicates with the air outlet pipeline 2 in the switching rod 1 to control different air output volumes. An air cavity cover 7 is also arranged on the blowing main body 4 to fix the two air cavities. When in use, the air outlet pipe 2 is controlled by the switching lever 1, and is switched and connected with the first air chamber 5 and the second air chamber 6 respectively. When the air outlet pipe 2 is connected to the first air chamber 5, the blowing body 4 controls the air output to form a paper bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com