A washing machine water inlet valve and water inlet method

A water inlet valve and washing machine technology, applied in the field of washing machines, can solve the problems of high power consumption, complicated structure setting, unfavorable practical promotion and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

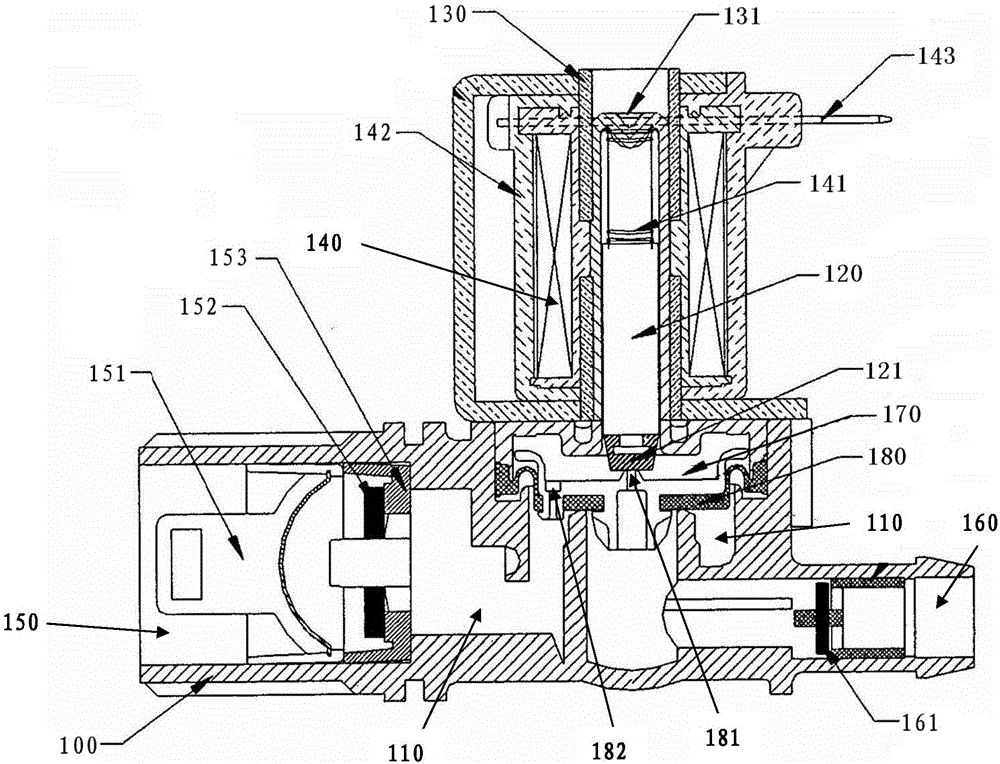

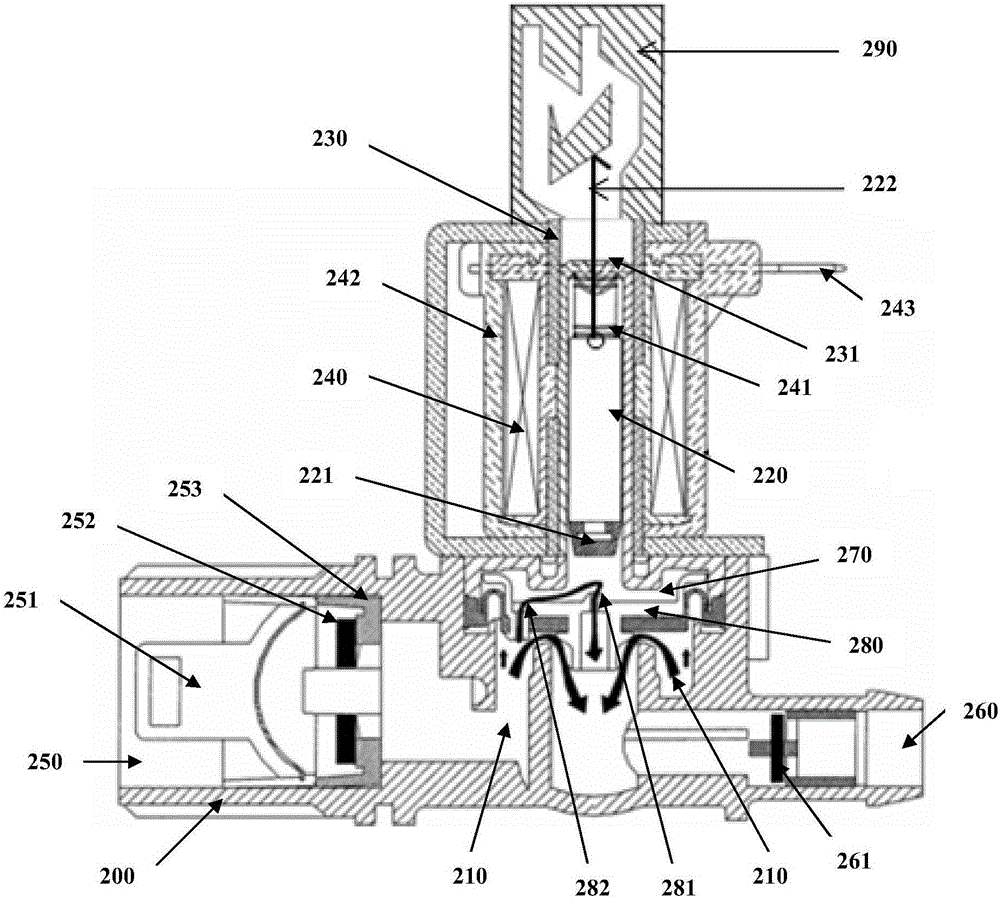

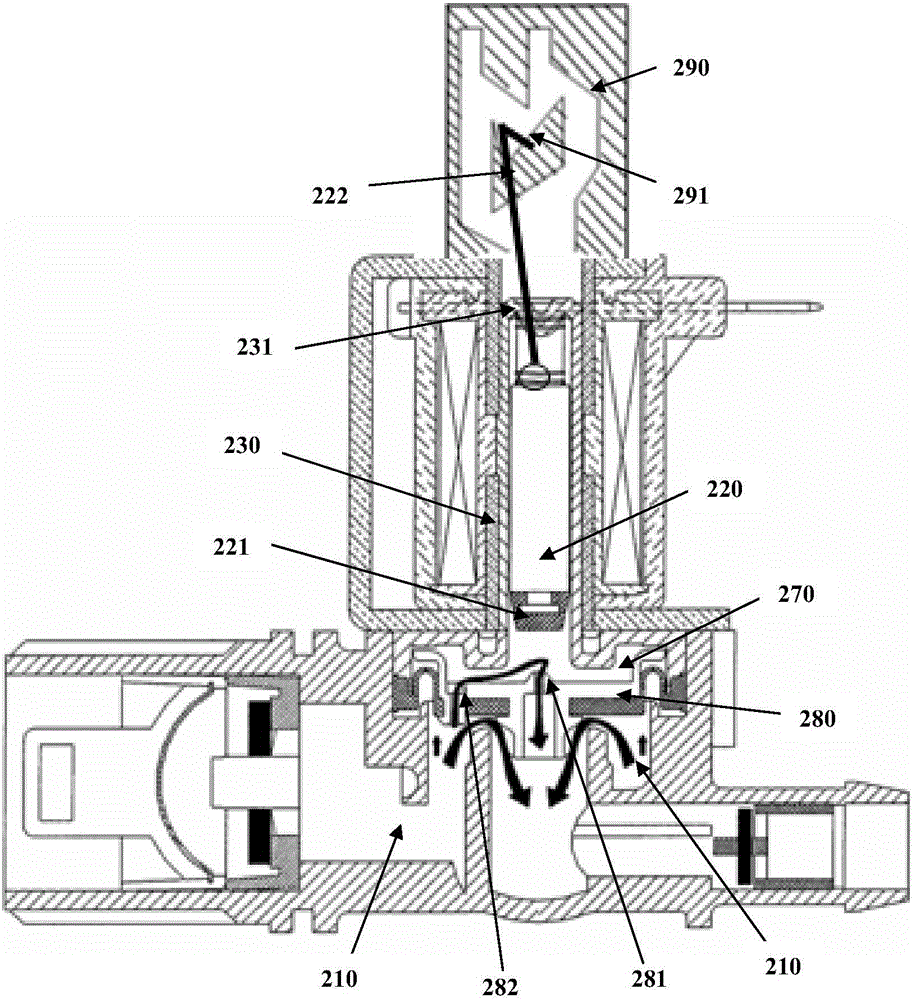

[0040] The embodiment of the invention discloses a water inlet valve for a washing machine, which includes a valve chamber, a sleeve, a valve core located on the inner circumference of the sleeve and movable up and down along the sleeve, an electromagnetic coil located on the outer circumference of the sleeve, and a water inlet located on the valve chamber. And the water outlet, the back pressure chamber under the sleeve and the diaphragm plate with a central hole, the upper end of the sleeve is provided with a guide groove, the guide groove is provided with a locking part, and the upper end of the valve core is fixed with a radial swing The hook, the electromagnetic coil adopts pulse-type electrification to generate pulse-type electromagnetic force on the valve core; among them,

[0041] The spool includes a first state, a second state and a third state;

[0042] The first state is: the lower end of the valve core is socketed and sealed with the central hole, and the hook is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com