Split type solar water heater with 315-degree circular arc-distributed tube

A solar water heater, split-type technology, applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc., to achieve the effects of expanding the total water-carrying capacity, good air venting performance, and prolonging the direct sunlight time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

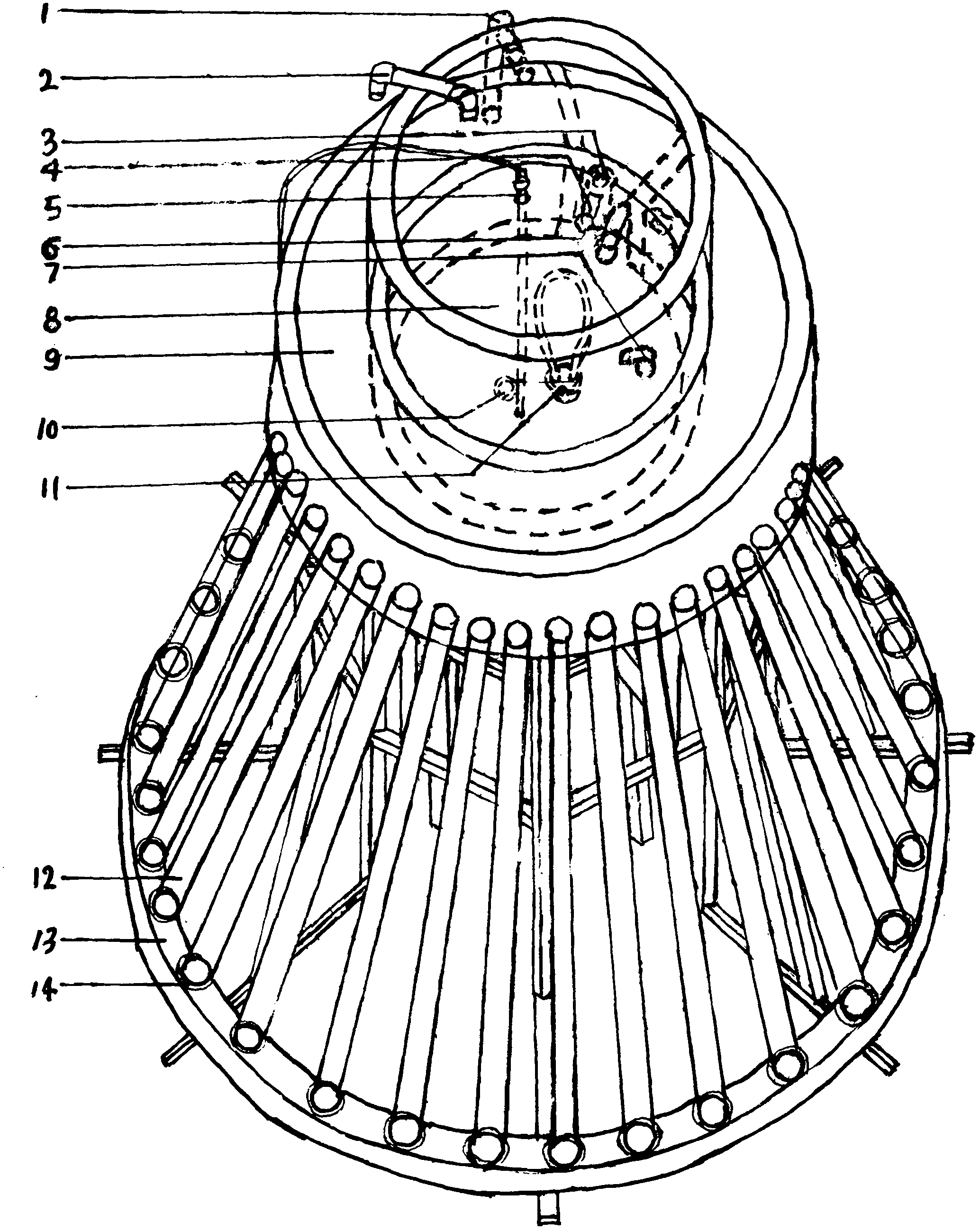

[0010] The split solar water heater with 315-degree arc pipe layout (see figure 1 ), it consists of the hot water pipe 1 from the arc-shaped intermediary water tank to the vertical water tank, the vent pipe 2, and the hot water pipe 4 from the vertical water tank to the outside. The hot water pipe 3 to the hot water valve of the user, the water temperature and water level detection rod and the insertion port of the rod on the top of the vertical water tank 5, the cold water pipe 6 that puts cold water from the vertical water tank into the arc-shaped intermediary tank, The cold water pipe 7 entering the bottom of the upright water tank from the outside, the upright water tank 8, the arc-shaped intermediary water tank 9, the drain valve 10 at the bottom of the upright water tank, the electric heater 11, and the glass heat collecting pipe 12, it has 28 or 35 in total root, each has three rubber sealing rings that seal with the socket of the arc-shaped intermediary water tank, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com