Fire starters and fire starter sets

A technology for ignition parts and connecting parts, applied in the field of pyrotechnics manufacturing, can solve the problems of transportation of ignition parts, increase the safety hazard in the production process, and it is difficult to determine the length of bridge wires, etc., so as to improve uniformity, avoid accidental detonation, and improve ignition consistency. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

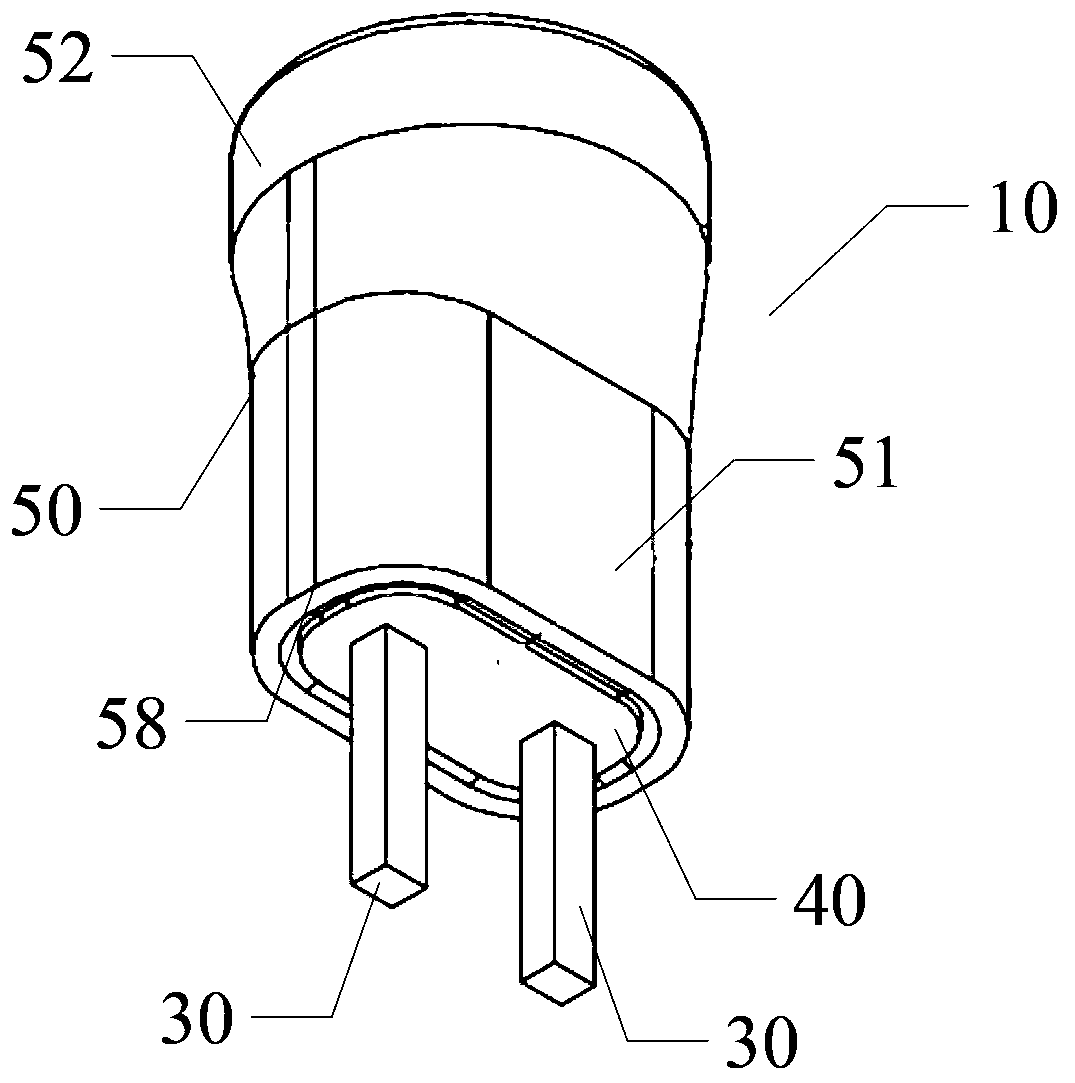

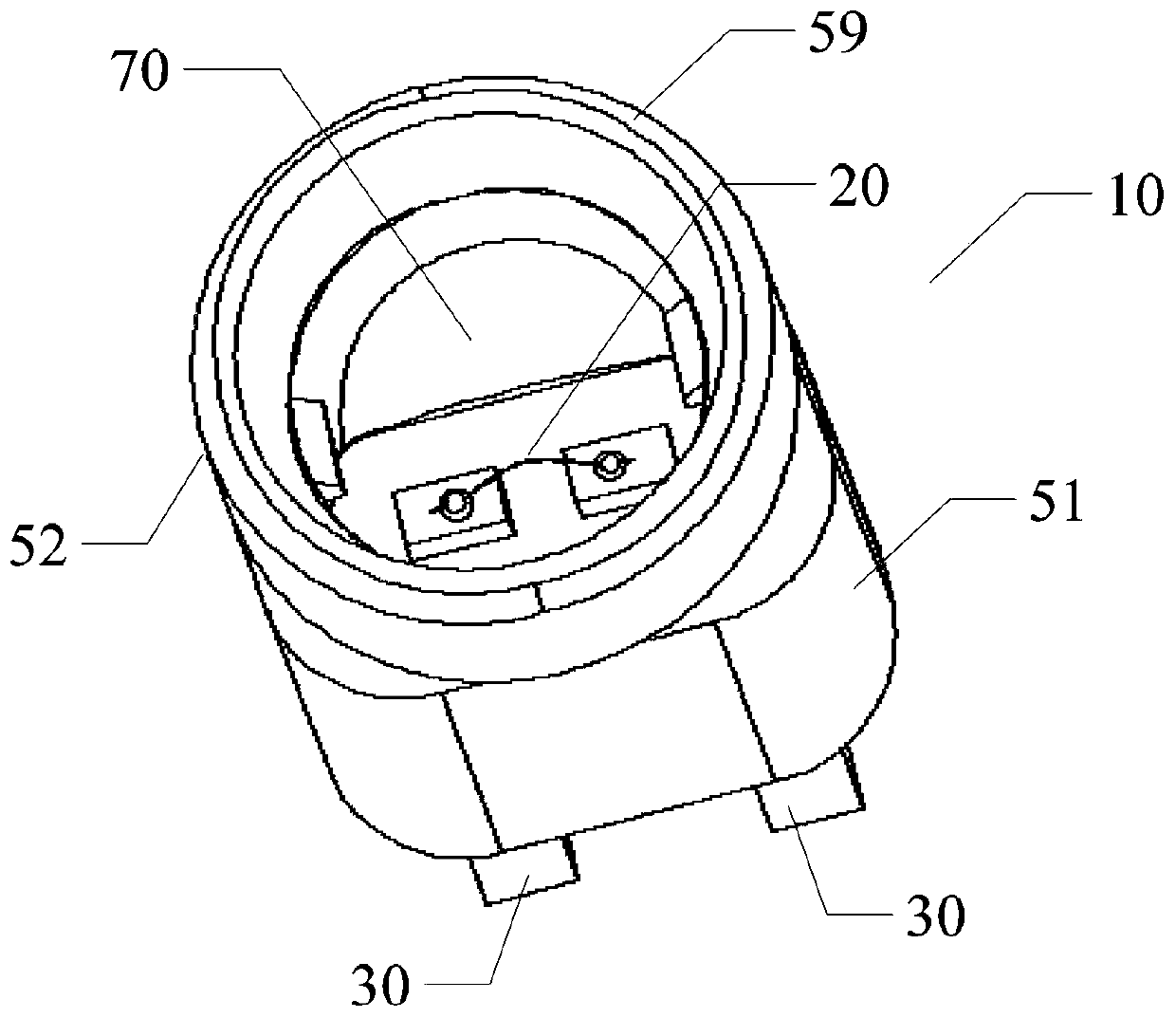

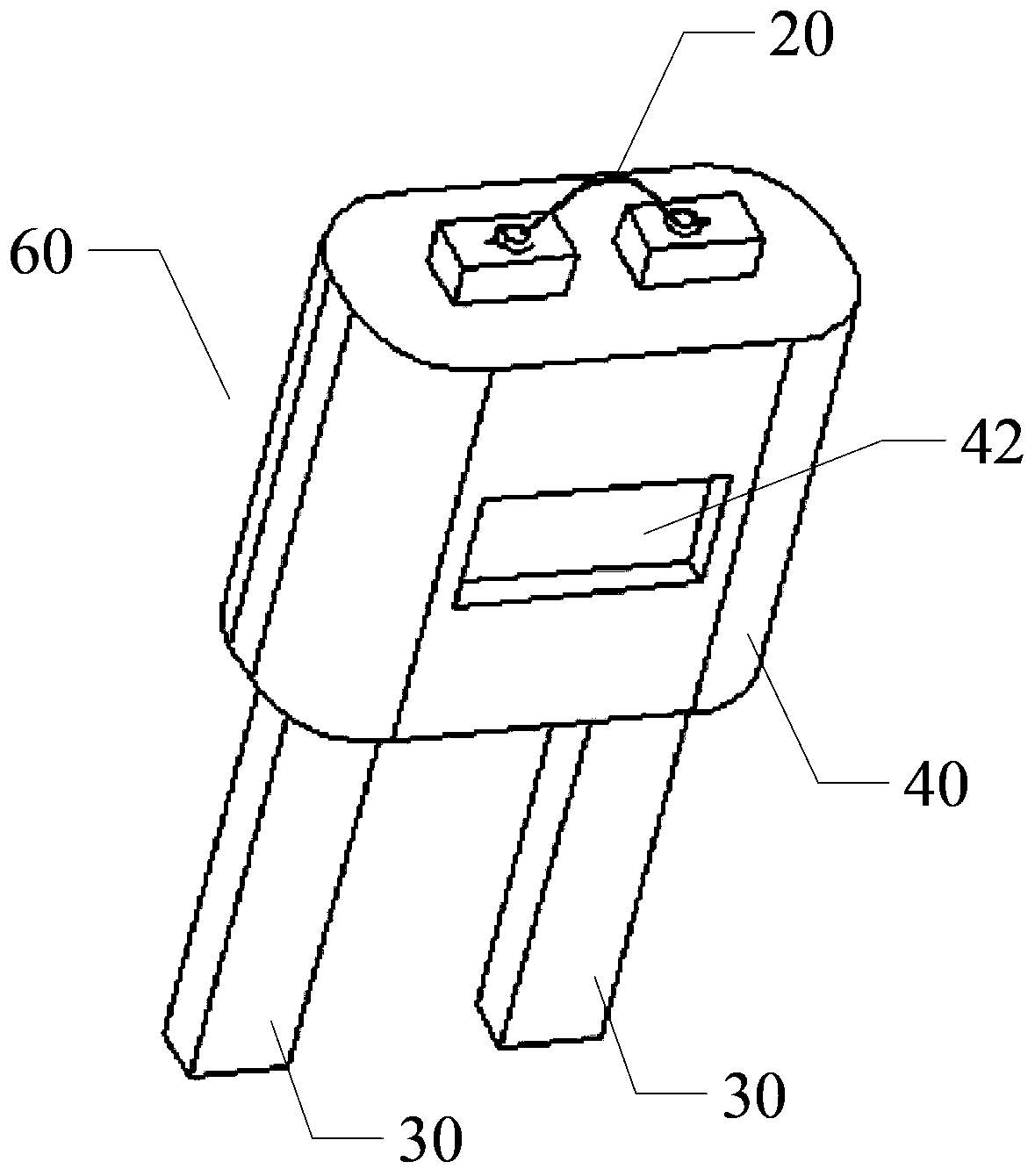

[0023] Fire starter 10 provided by the present invention, see figure 1 and figure 2 As shown, it is used to connect with the ignition control circuit board. In particular, the above-mentioned fire starter 10 includes an ignition bridge wire 20, a pair of bridge wire connectors 30, a base 40 and a cavity shell 50, the ignition bridge wire 20, a pair of bridge wires Connector 30, and base 40 jointly form an assembly 60, such as image 3 As shown; a pair of bridge wire connectors 30 are fixed by the base 40 and are insulated from each other; two ends of a pair of bridge wire connectors 30 extend out of the base 40, and one end is welded with an ignition bridge wire 20, so that a pair of bridge wire connectors 30 to form an electrical connection, and the other end is used to form an electrical connection with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com